Tunnel lining surface intelligent marking robot

A robot and lining technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of low construction efficiency, inability to realize intelligent construction and rework of auxiliary facilities on the surface of tunnel lining, and achieve the effect of high-precision construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

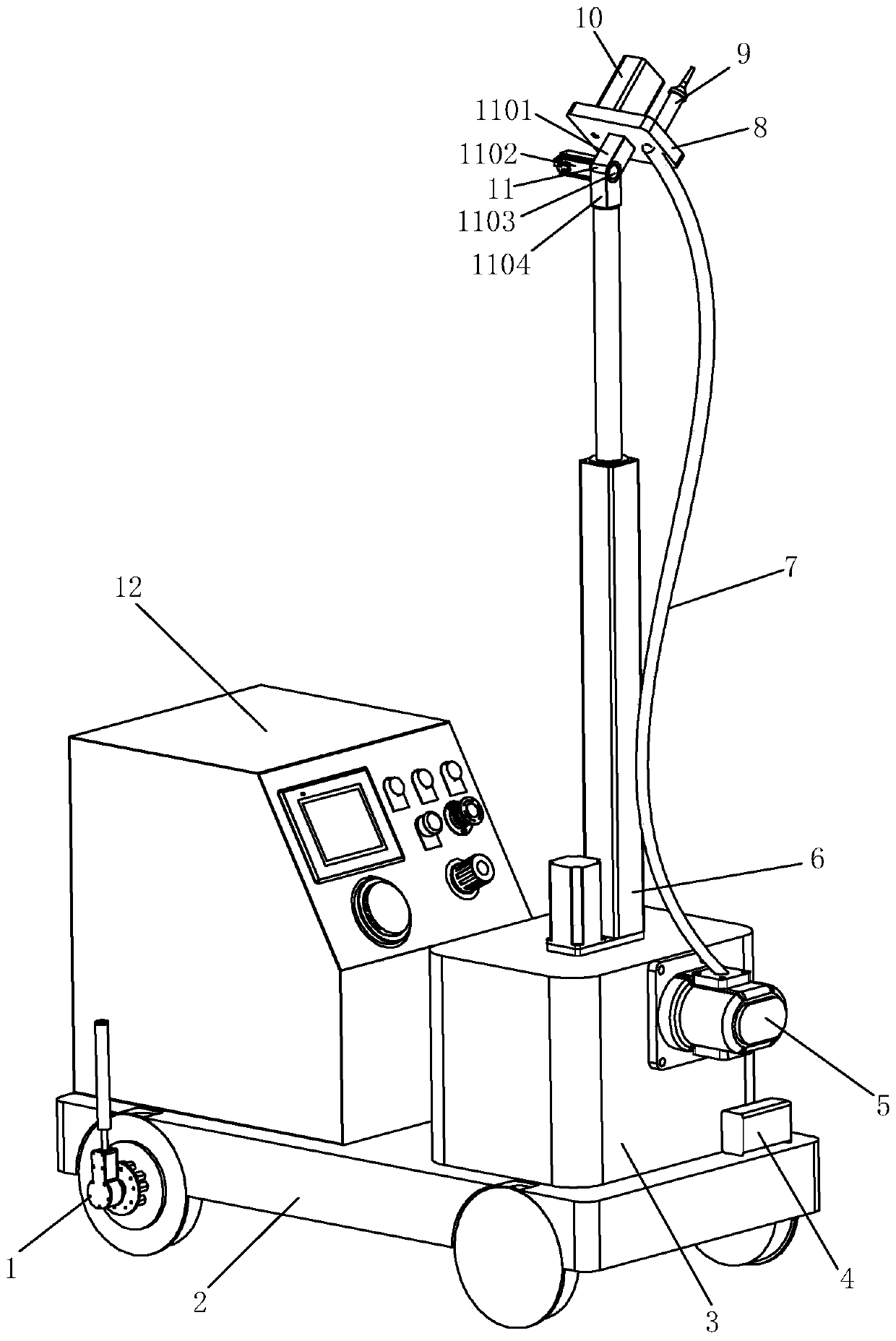

[0015] The intelligent scribing robot on the tunnel lining surface includes a wheeled chassis 2, a distance measuring device 1, a paint storage box 3, a horizontal laser range finder 4, a vertical laser range finder 10, a hydraulic pump 5, and a pipeline 7 , electric cylinder 6, angle regulator 11, marking platform 8, nozzle 9, control cabinet 12.

[0016] The wheeled chassis 2 is front-wheel steering, and the size of the platform plate of the wheeled chassis 2 is 1000mm×600mm; the speed measuring device 1 is an absolute value extension shaft encoder, the model is SICK-DFS60E-T5AM01024, and when installed, the extension The shaft is concentric with the right rear wheel tire; the paint storage box 3 is welded by stainless steel plates with a thickness of 0.5mm, and is fixed on the wheeled chassis 2 through bolt connection. A thick platform plate with a size of 400mm×300mm; the horizontal plane laser rangefinder 4 is fixed on the platform plate of the wheeled chassis 2 through b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com