Automatic labelling pretreating device for inserting core of sensor housing and use method

An automated device and preprocessing technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as difficulty in matching customers' high-volume requirements, hidden dangers of batch quality problems, and low work efficiency, and achieve power consumption. Small, perfect system, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

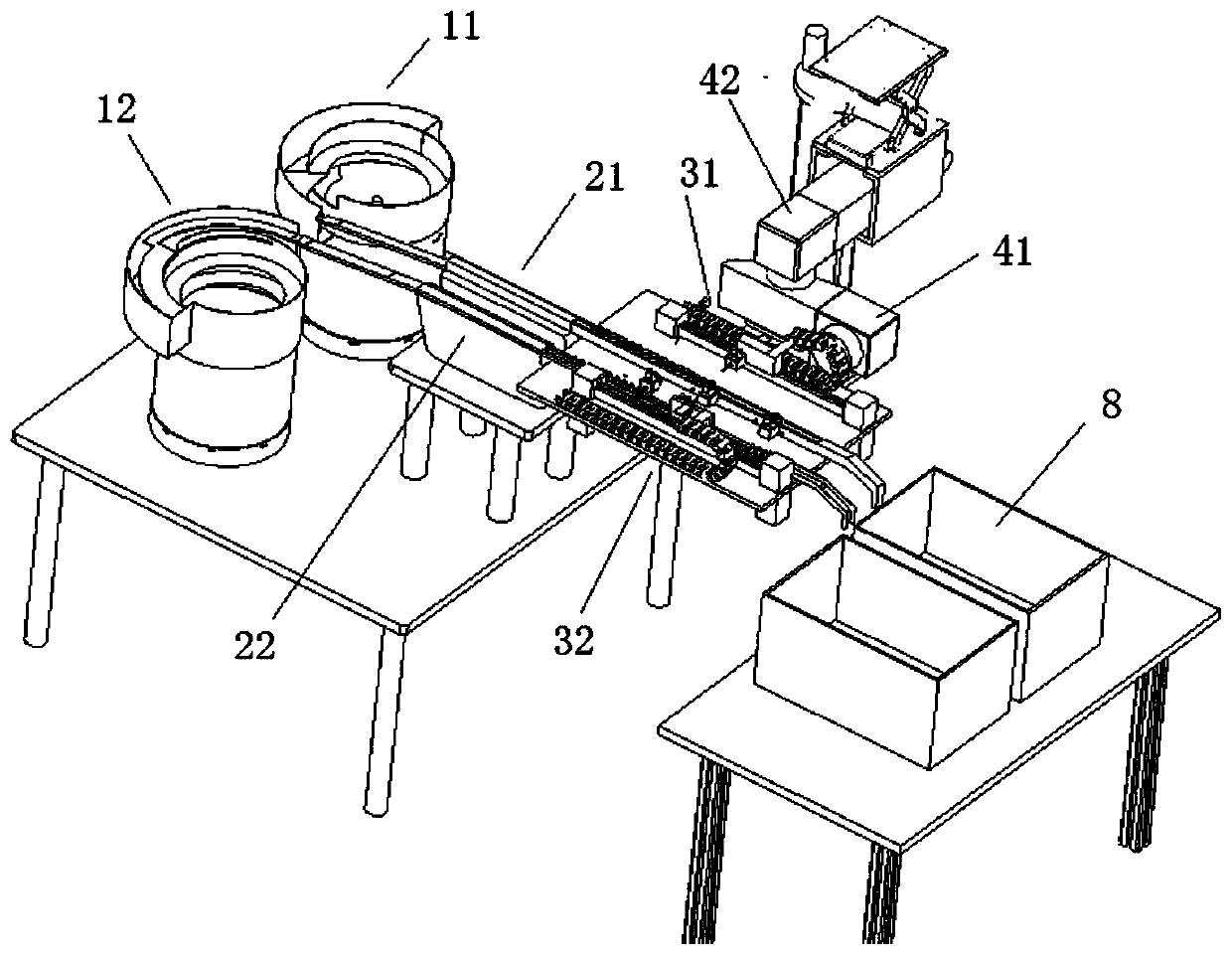

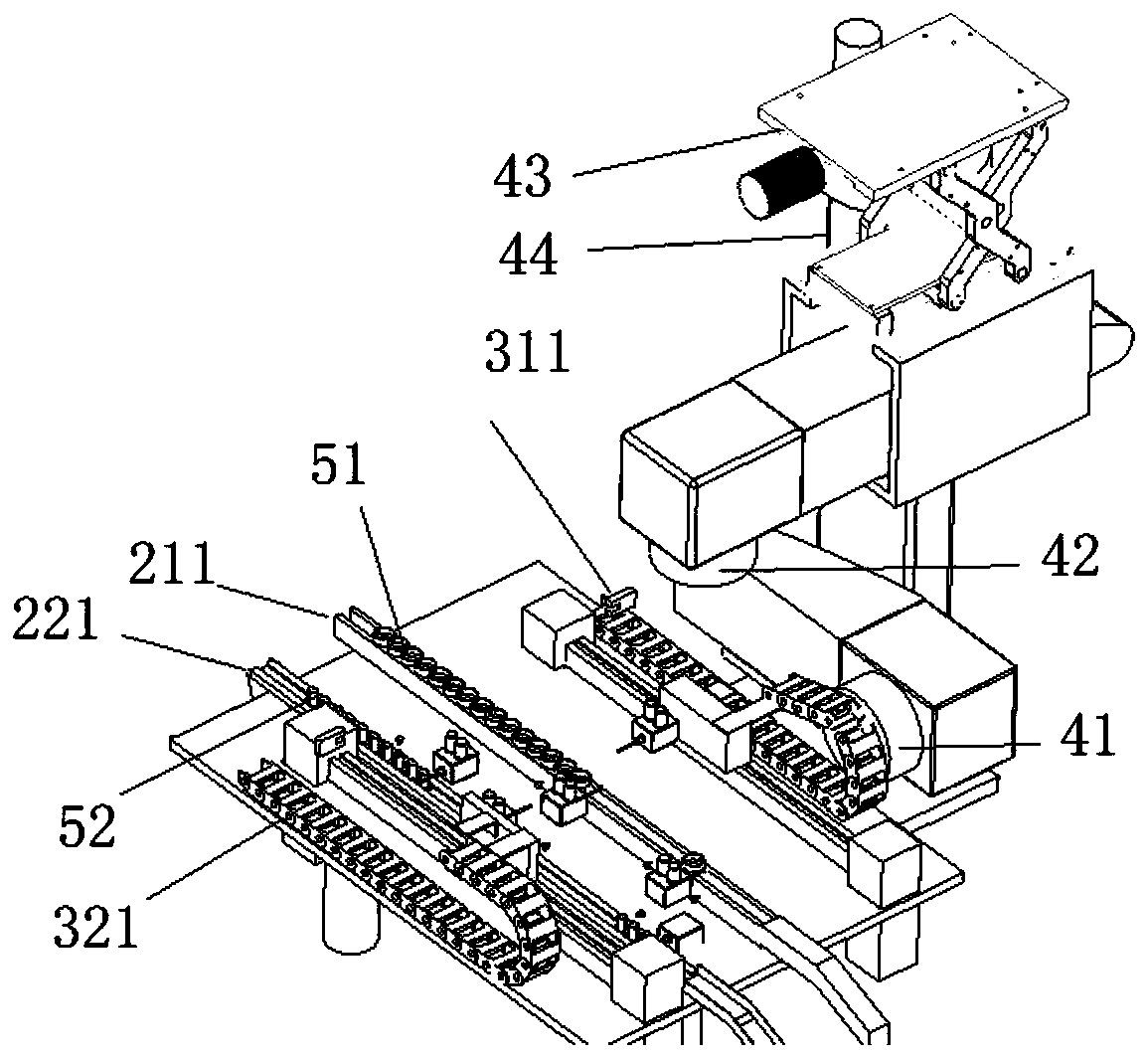

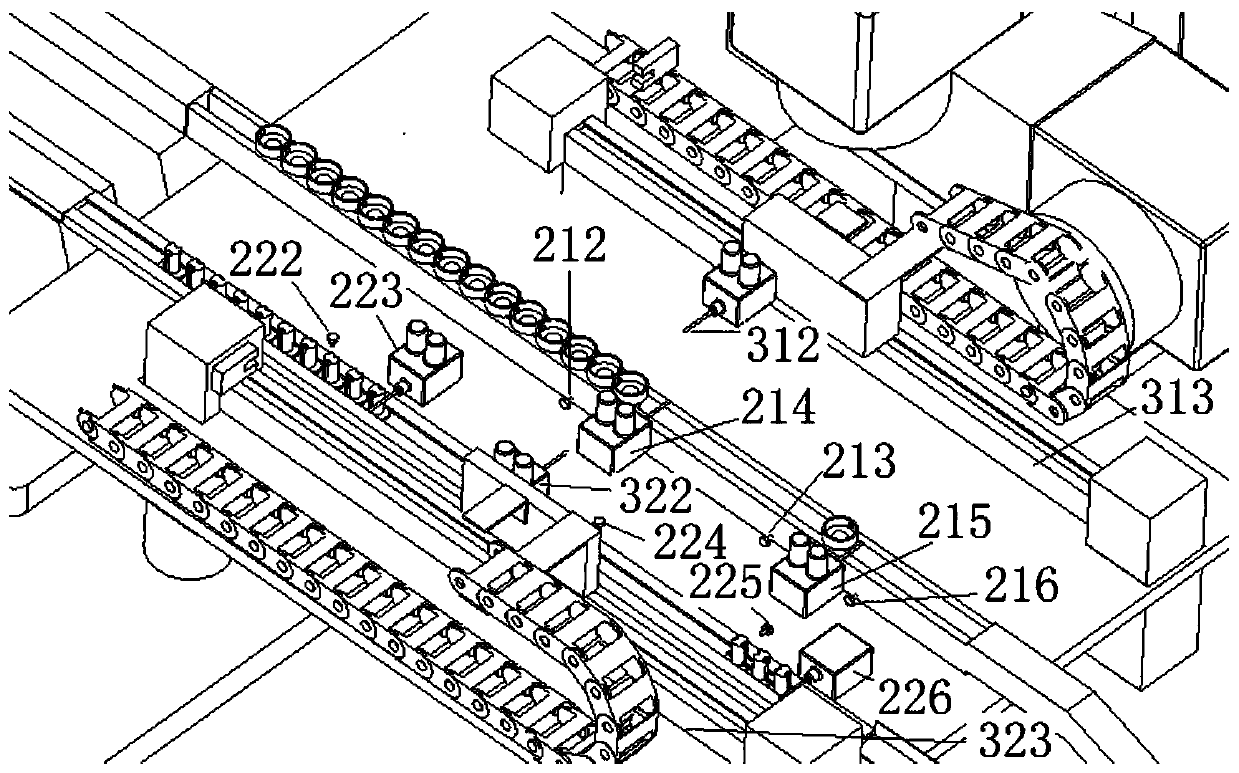

[0043] Referring to the accompanying drawings, it can be seen that the marking pretreatment automation device for the sensor shell ferrule includes a first feeding mechanism 11, a second feeding mechanism 12, a first transport mechanism 21 connected to the first feeding mechanism 11, and a second feeding mechanism 12 Connected second transport mechanism 22, first push mechanism 31, second push mechanism 32, first laser head 41, second laser head 42;

[0044] The first feeding mechanism 11 sends the shell 51 to the first transportation mechanism 21, and the second feeding mechanism 12 sends the ferrule 52 to the second transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com