Charging loop cooling structure

A cooling structure and charging circuit technology, which is applied to circuits, electrical components, insulated cables, etc., can solve problems such as difficult heat dissipation, burning of the charging connection port, poor leak-proof performance, etc., and achieve improved connection reliability, safety and reliability, and low cost. Excellent cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

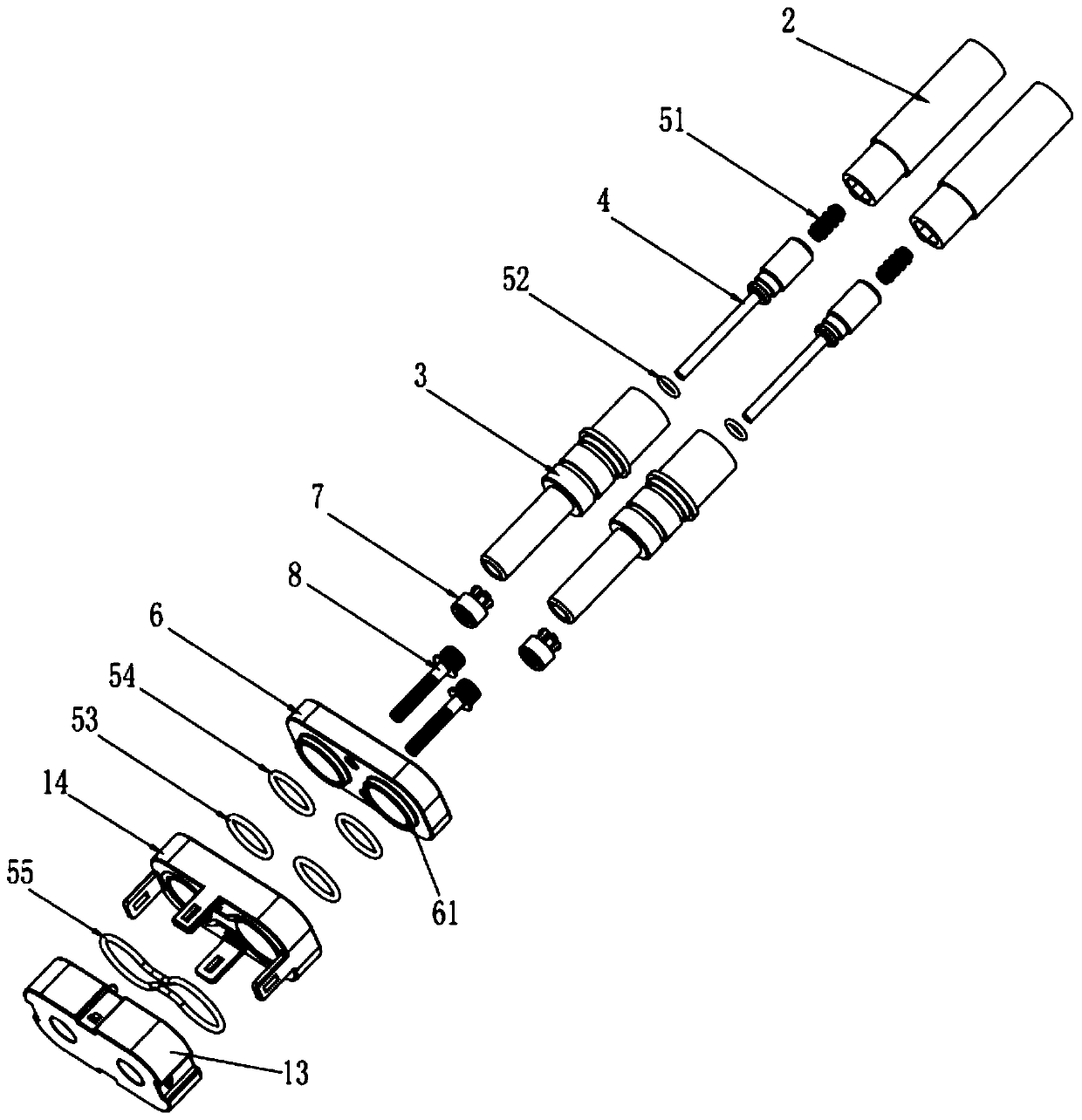

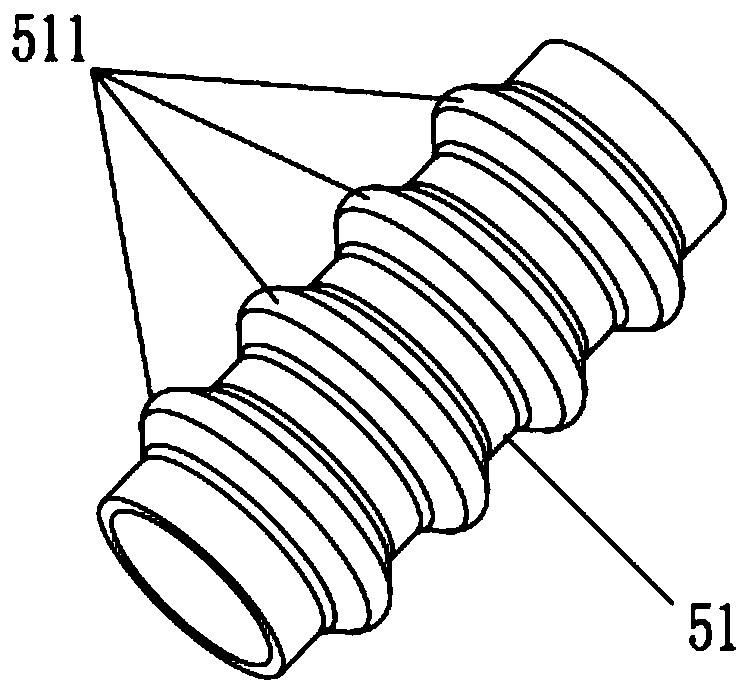

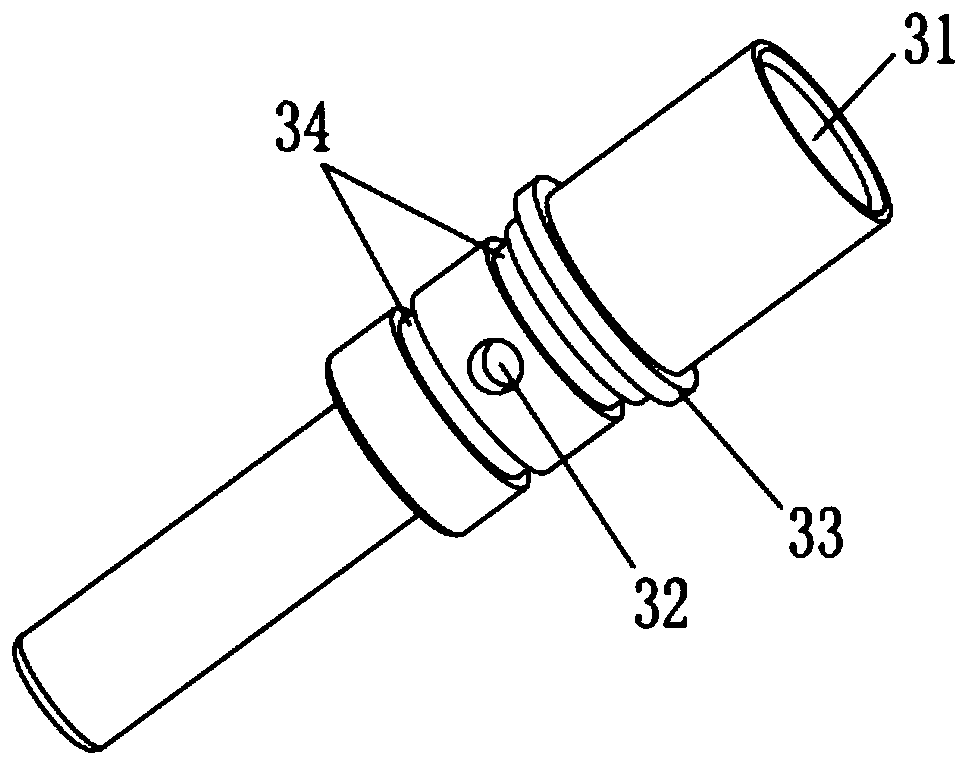

[0026] Such as Figure 1 to Figure 5 As shown, a charging circuit cooling structure shown in this embodiment includes a fixed part 1 and two jack terminals 3 sealed and penetrated in the fixed part 1 for connecting with the cable 2, and the middle of the cable 2 is provided There is a guide tube 21 for the flow of cooling medium. Specifically, the cable 2 includes a guide tube 21, a copper layer 22 and an insulating layer 23 from the inside to the outside. The rear end of the jack terminal 3 is opened in the middle of the axial direction slot 31, the slot 31 is provided with a pin 4 connected to the guide tube 21, the axial middle of the pin 4 is provided with a through hole 41 communicating with the guide tube 21, and the front end of the pin 4 extends to the groove The bottom of the hole 31, and the front end and surroundings of the pin 4 and the slot 31 are provided with a gap communicating with the through hole 41 for the flow of the cooling medium. The opposite sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com