Automatic ladder type fuel delivery device

A transmission device and escalator technology, applied in the field of material transmission, can solve the problems of aggravating the retention and vibration of fuel balls in pipelines, fuel loss of power source, and radioactive leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is described in detail as follows:

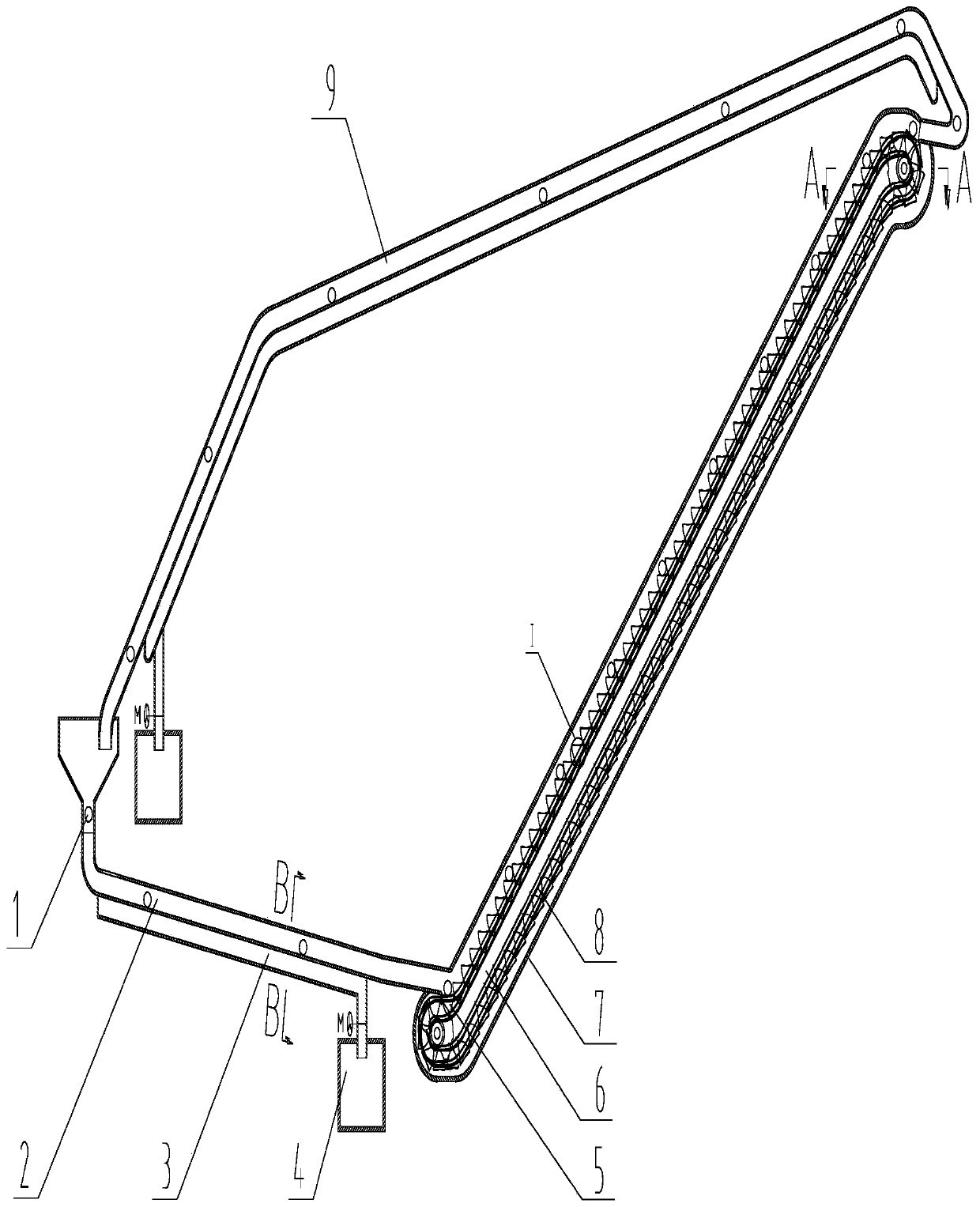

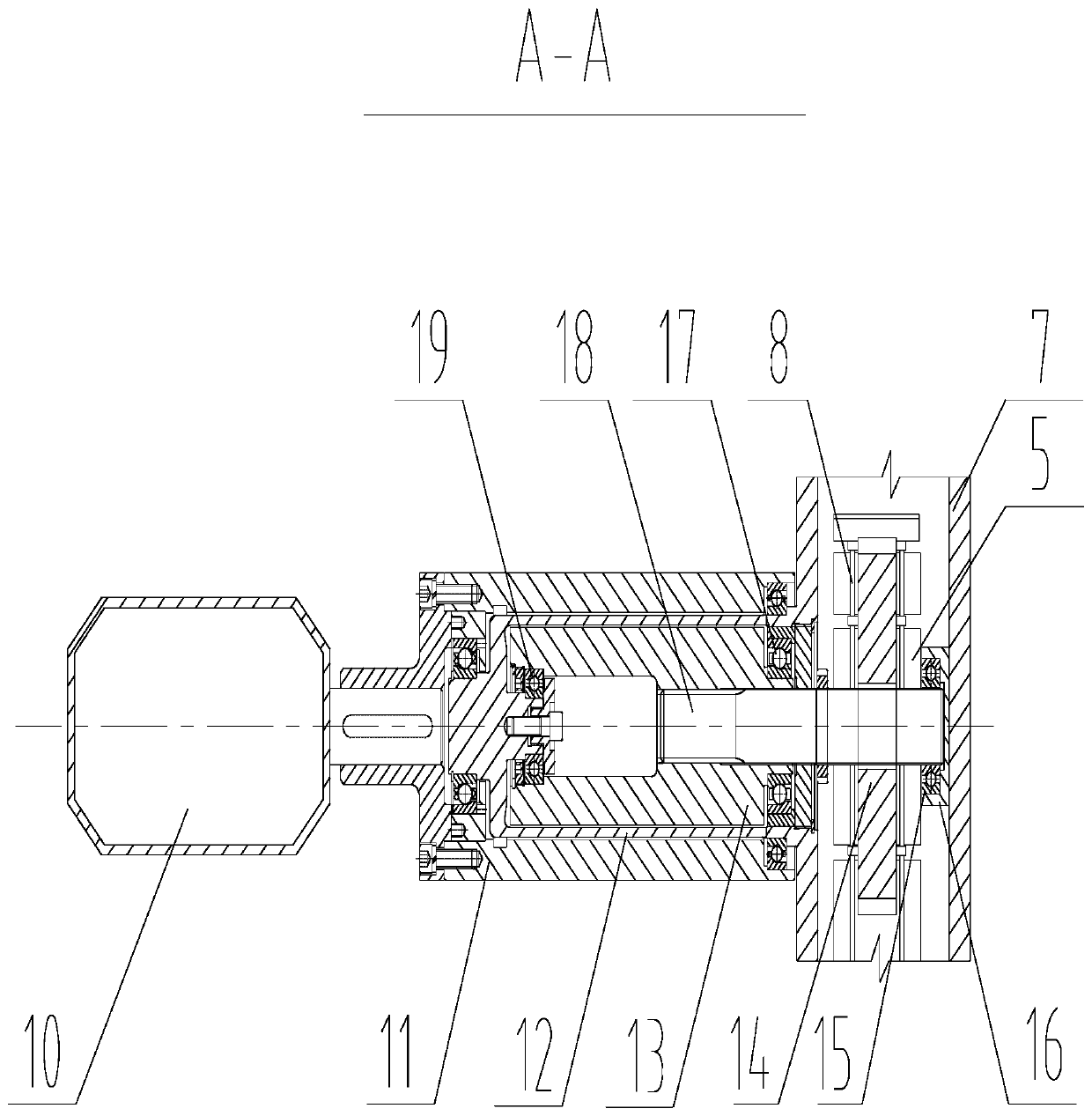

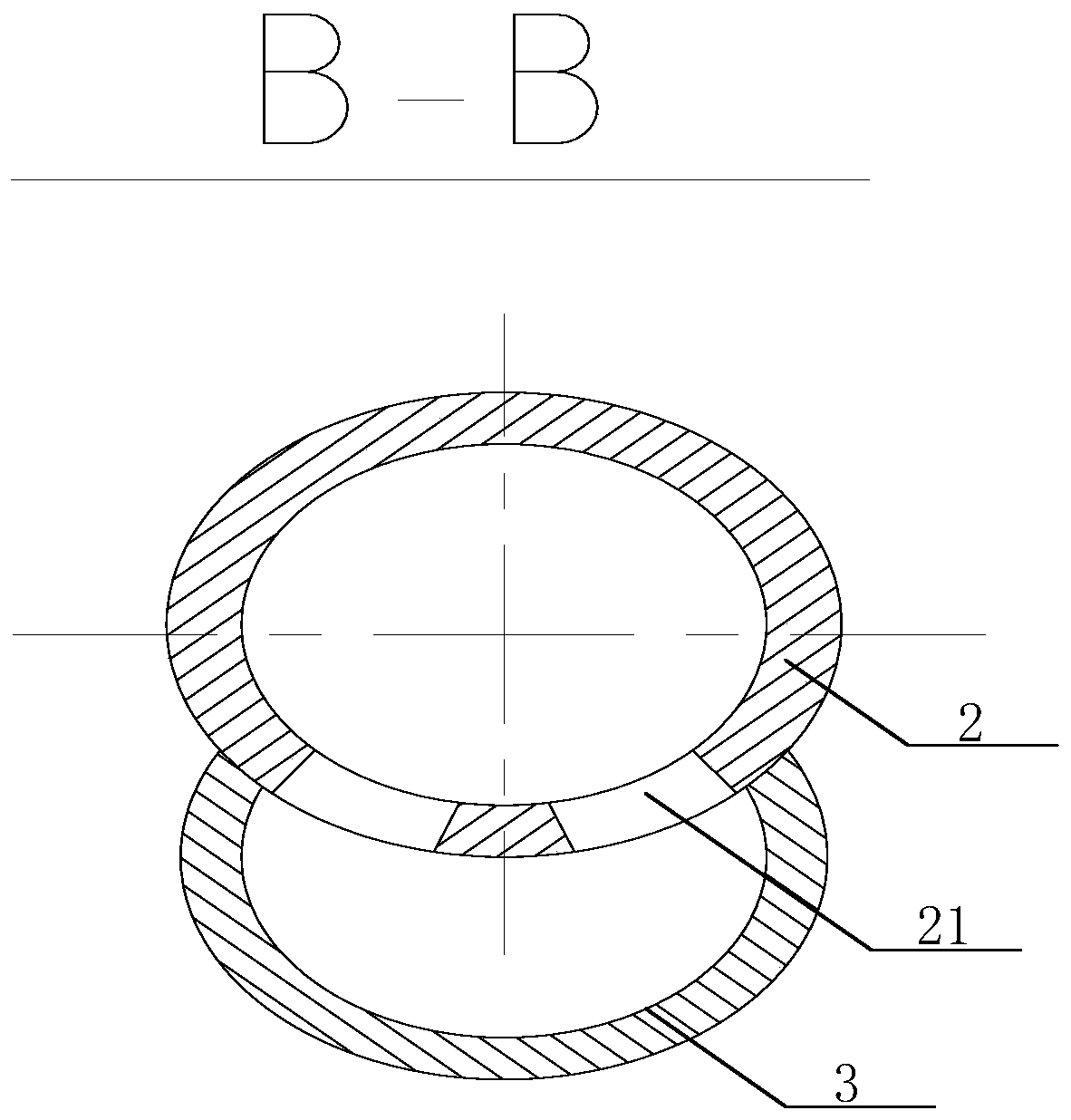

[0019] A kind of escalator type fuel transmission device of the embodiment of the present invention, see figure 1 , figure 2 , including a sealed containment body 7 containing helium, a mechanical transmission part 6 located in the containment body 7, and a drive motor 10 and a permanent magnet coupling located outside the containment body 7; the upper and lower ends of the containment body 7 are respectively connected to the gravity The passive slotted raceway (2, 9) is connected, and the bottom of the slotted raceway (2, 9) is provided with a dust conveying pipe 3 for collecting dust and debris falling through the slotted raceway. The end of the conveying pipe communicates with the dust collection device 4; the mechanical transmission part 6 includes a transmission ratchet 14, a drive chain 8 fixed on the transmission rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com