Tunable metamaterial polarizer and manufacturing method thereof

A technology of metamaterials and polarizers, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as difficulty in integration, size reduction, and large size, and achieve the effects of easy integration, size reduction, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiment of the present invention provides a tunable metamaterial polarizer and its manufacturing method, which solves the technical problems of large volume, difficulty in integration, and very limited working wavelength range in the prior art, and realizes reduced volume, easy integration, and broadened working range. The technical effect of the applicable range of wavelengths.

[0035] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

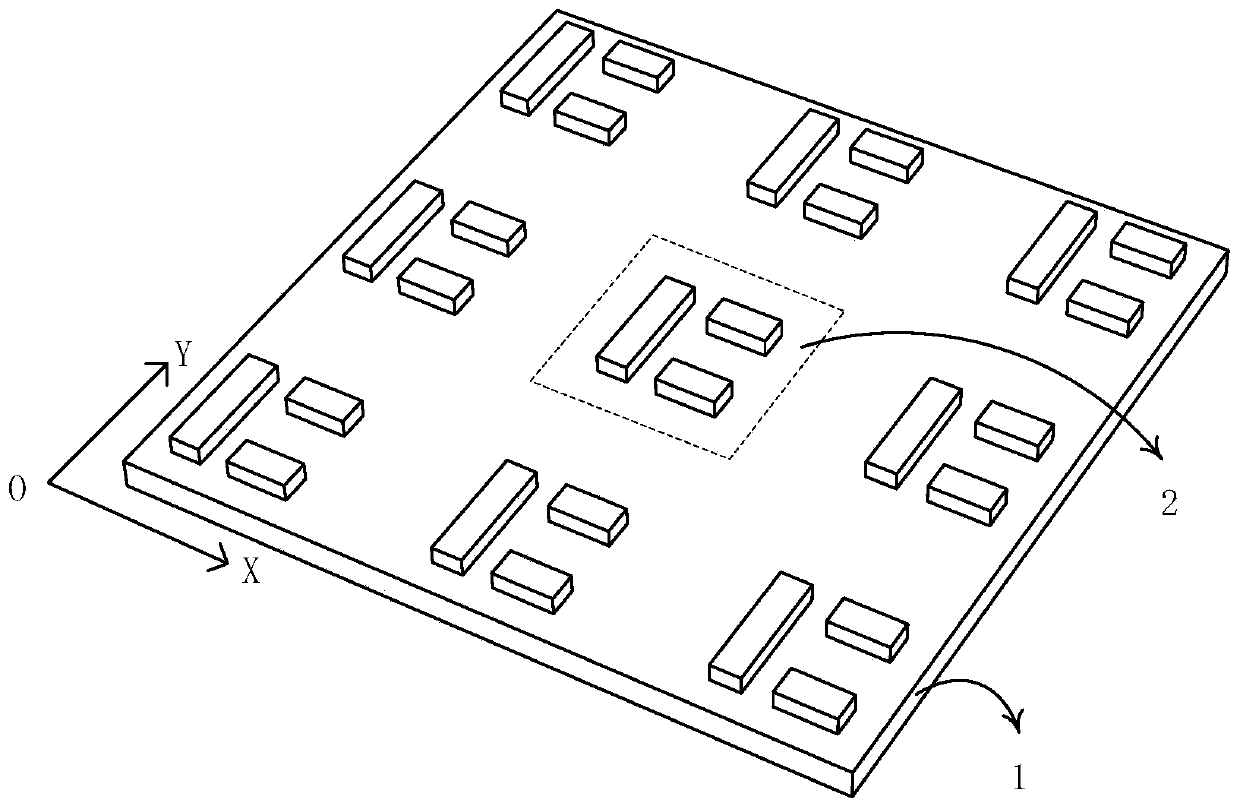

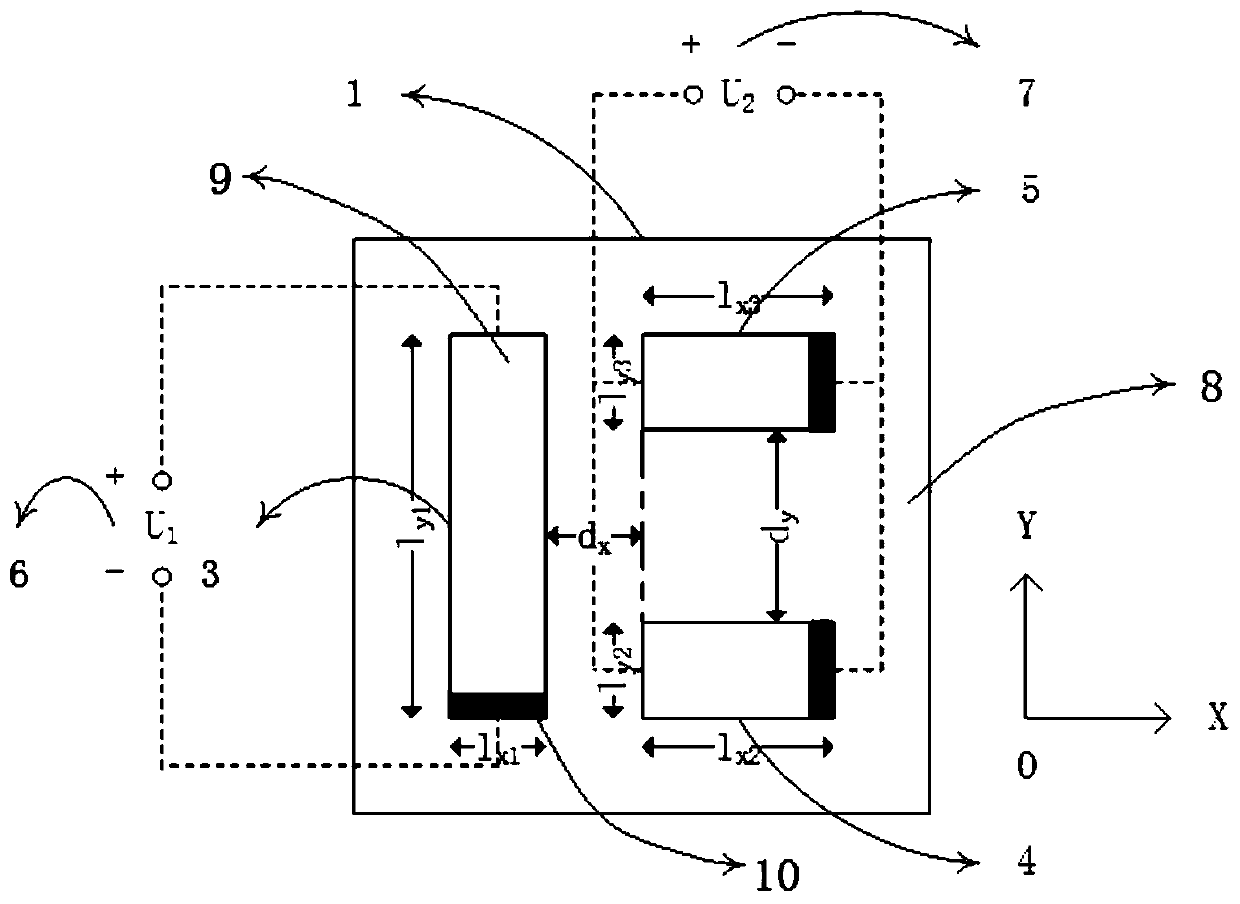

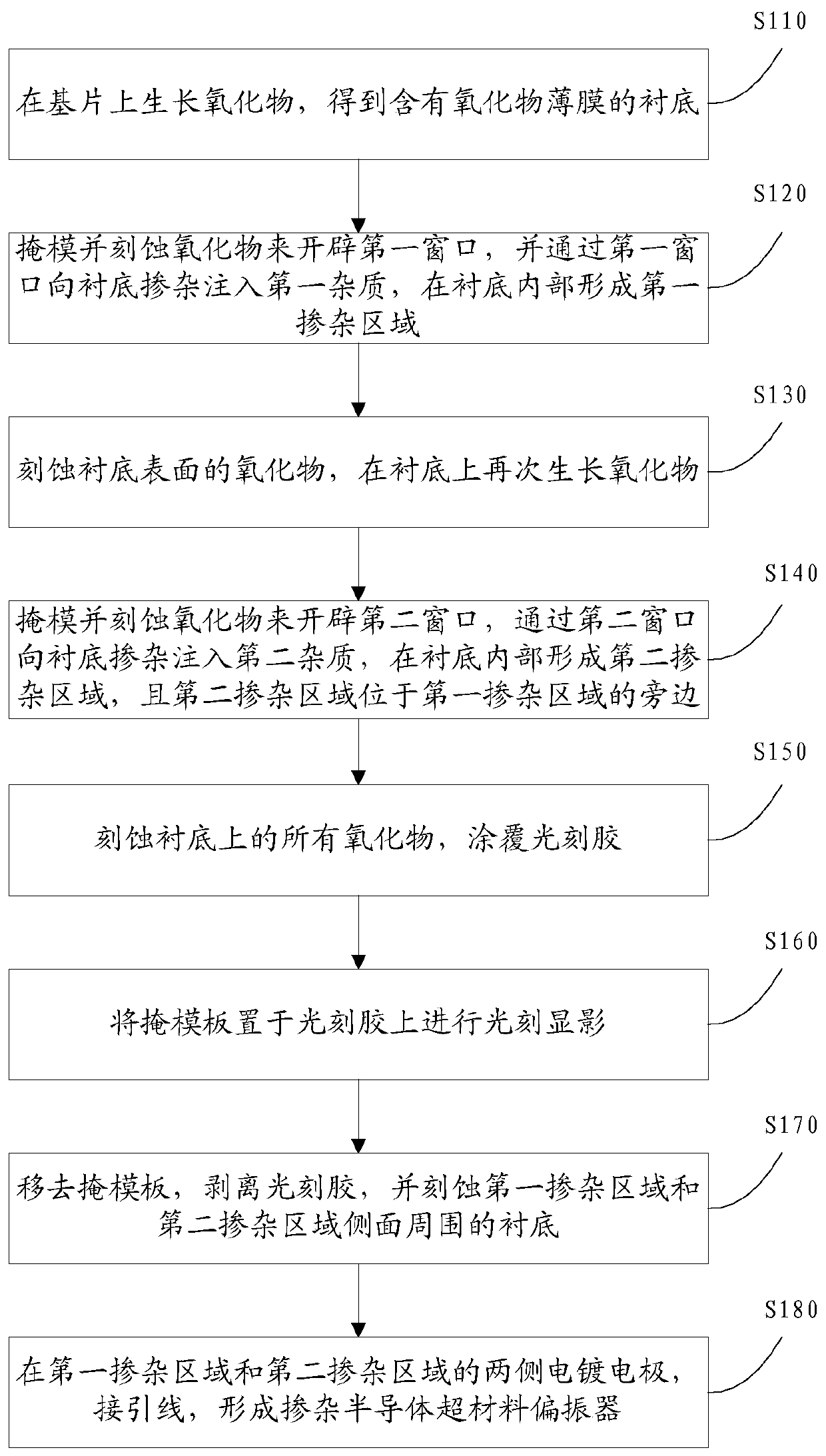

[0036] A metamaterial array composed of a doped semiconductor metamaterial resonant unit on the substrate, the first power port of the resonant unit is connected to the positive pole of the regulating power supply, and the second power port of the resonant unit is connected to the negative pole of the regulating power supply, avoiding the linear polarization The polarizer is constructed by using a polarizer and a quarter-wave plate, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com