Self-driving high precision angle measuring system and method

An angle measurement, high-precision technology, applied in measuring devices, instruments, electrical devices, etc., can solve the problems of complex circuits and large measurement errors, and achieve the effect of simple and compact structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

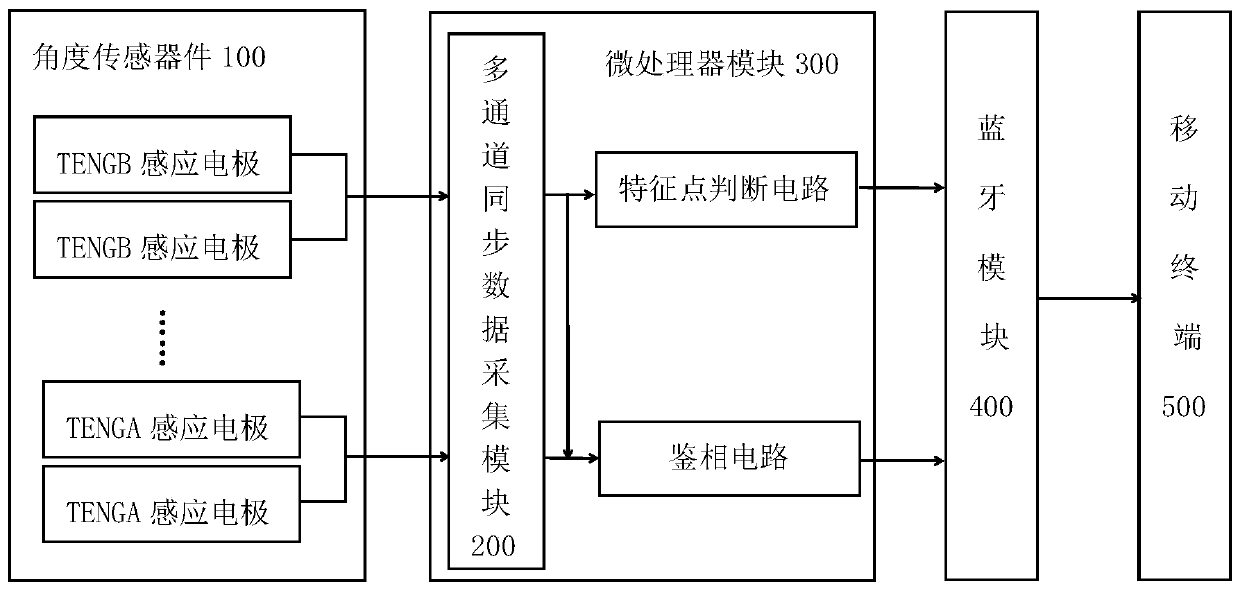

[0034] Such as figure 1 As shown, this embodiment proposes a self-driven high-precision angle measurement system, which includes an angle sensor 100 , a multi-channel synchronous data acquisition module 200 , a microprocessor module 300 , a communication module 400 and a mobile terminal 500 .

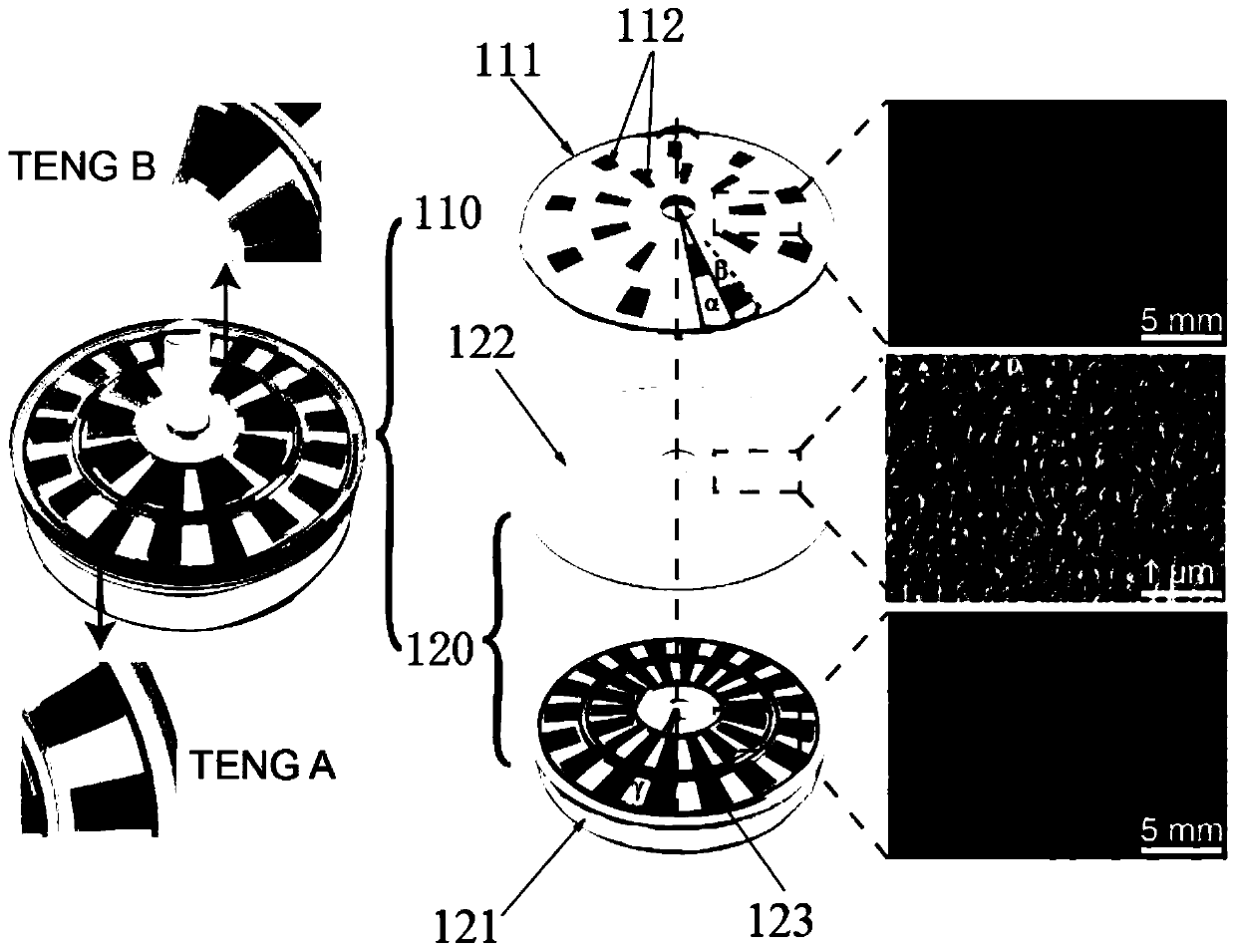

[0035] This embodiment utilizes the triboelectric charge generated during the rubbing process between metal copper and Kapton (polyimide) film and the spatial position change of the electrostatically induced charge to realize the direct sensing of the rotational motion: two planes that are in contact with each other during the rubbing process Due to the difference in their ability to obtain electrons, they will be charged with frictional charges of equal magnitude and different sign. When one of the planes is rotated relative to the other plane, the spatial position of the frictional charges will also change accordingly, which will lead to positive and negative electrodes. The amount of...

Embodiment 2

[0053] Corresponding to Embodiment 1 above, this embodiment proposes a self-driven high-precision angle measurement method, such as Figure 5 As shown, the method includes:

[0054] S500. Using at least two sets of frictional nanogenerators to generate friction through rotational driving of the rotating member to be tested to generate alternating current signals respectively, and there is a phase difference between the alternating current signals generated by the frictional nanogenerators.

[0055] S510, synchronously collect the generated AC signal, and transmit it to the microprocessor module 300 for processing and calculation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com