High-pressure flange sealing structure used on heat exchange device header

A heat exchange device and flange sealing technology, which is used in the sealing of engines, heat exchanger shells, heat exchange equipment, etc., can solve the problems of frequent replacement of flat gaskets, difficulty in ensuring the flatness of the flange connection surface, etc., and achieve smooth movement. , reduce friction resistance, improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

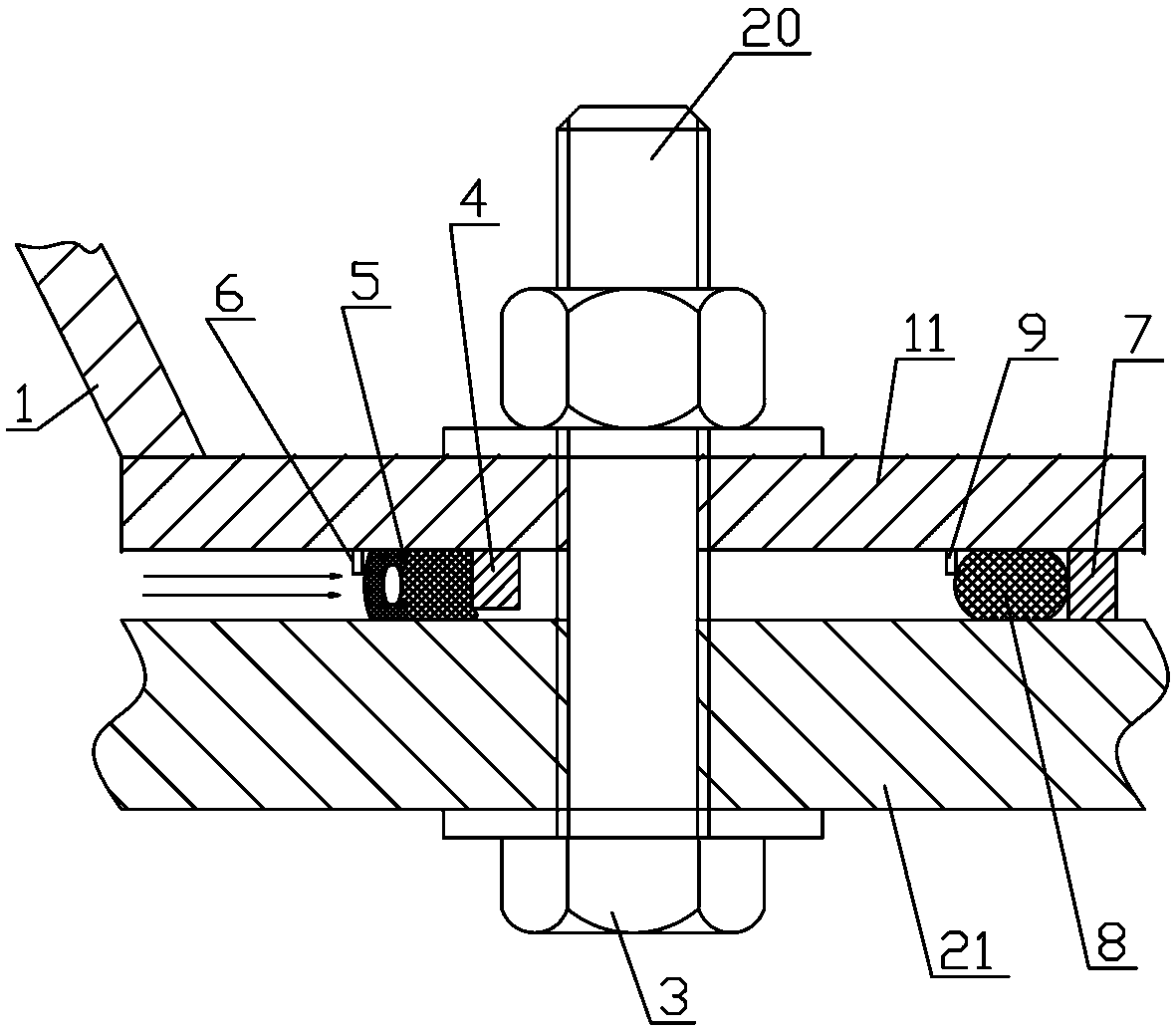

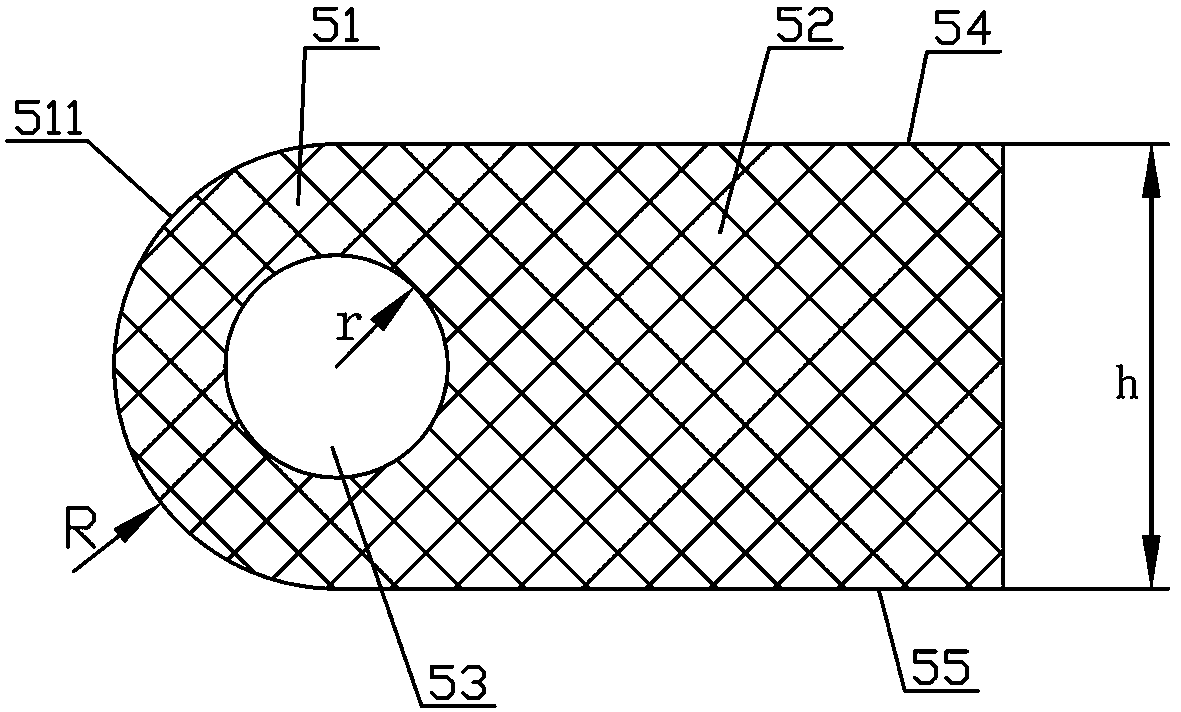

[0017] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

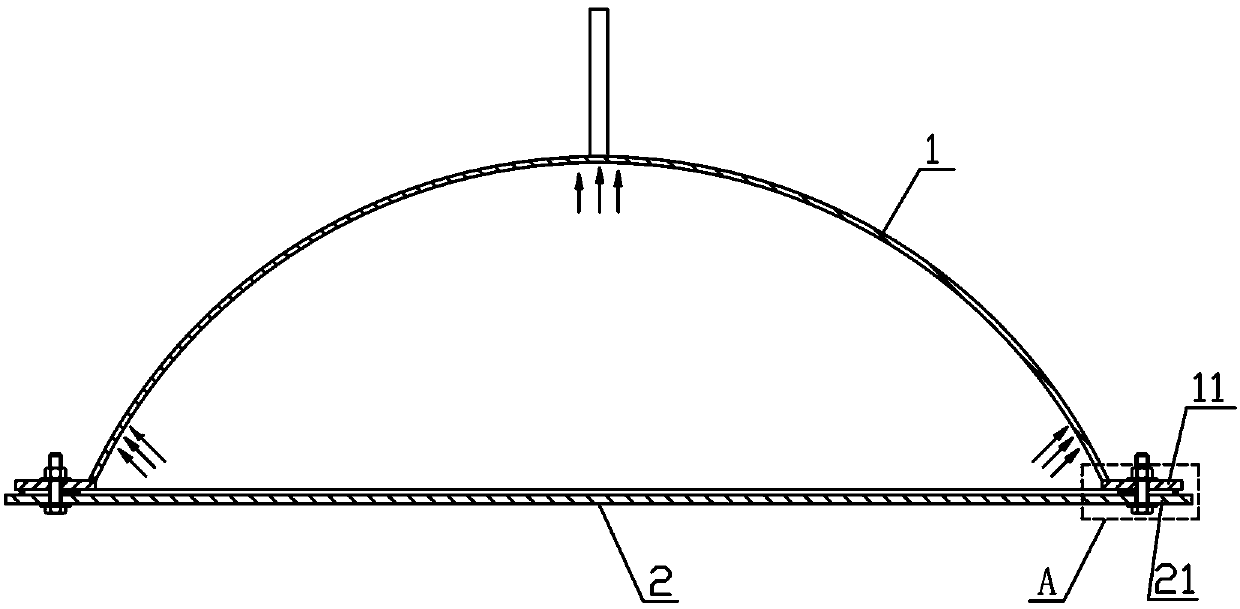

[0018] This application is aimed at the sealing problem existing when replacing the butt joints with headers instead of the elbow-shaped butt joints used to connect the heat exchange tubes in the original heat exchange device, and is designed for a heat exchange device. High-pressure flange sealing structure on the header. The sealing structure of the high-pressure flange used on the header of the heat exchange device is described here in combination with one of the header structures of the heat exchange device, and the sealing structures in the other headers are the same. Such as figure 1 As shown, the header is composed of the header body 1 and the header side plate 2, and a number of through holes corresponding to the heat exchange tubes are arranged on the header side plate 2, and each heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com