Hole spacing measuring instrument

A technology for measuring instruments and hole distances, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., can solve the problems of uncontrollable drilling depth, etc., and achieve improved quality and aesthetics, convenient operation, and equipment structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

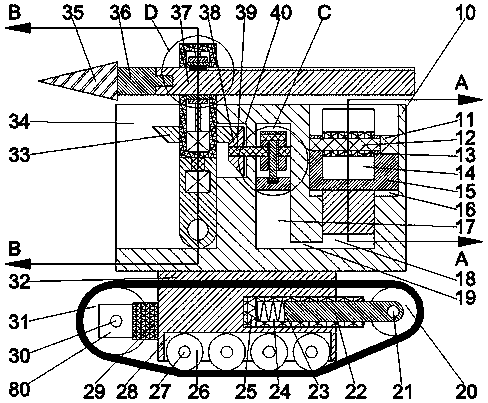

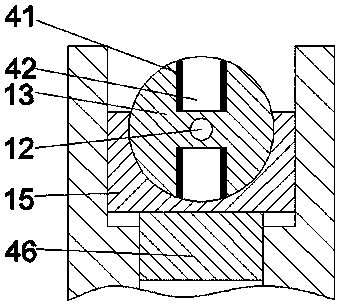

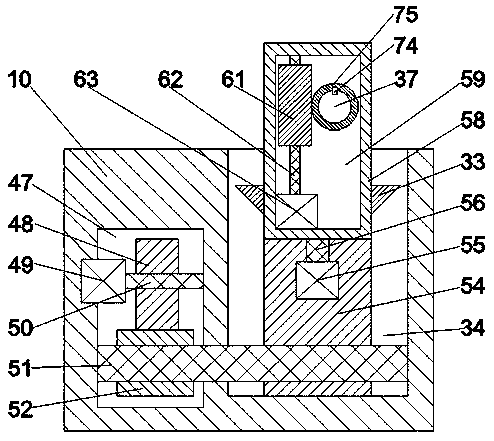

[0017] like Figure 1-Figure 5As shown, a hole distance measuring instrument of the present invention includes a main body 10, a chassis 32 extending downward is fixed on the bottom end surface of the main body 10, and a retractable opening is provided on the left end surface of the main body 10. Groove 34, the top end surface of the main body 10 is provided with a lifting chute 16, and the end wall on the right side of the receiving groove 34 is provided with a bevel gear chamber 40, and the main body located on the right side of the bevel gear chamber 40 10 is provided with a first hydraulic chamber 17 extending downward, and a hydraulic pipeline 19 extending left and right is fixed in the main body 10 below the first hydraulic chamber 17, and the left extension end of the hydraulic pipeline 19 is It communicates with the extension end of the bottom of the first hydraulic chamber 17, and a second hydraulic chamber 18 extending downward is opened on the bottom end wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com