Card drilling clamp and drilling method with same

A drilling jig and card technology, which is applied in the field of smart card processing and testing equipment, can solve problems such as affecting the market launch of cards, scratching inherited circuit chips, affecting card detection, etc., and achieves shortened detection links, high drilling efficiency and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

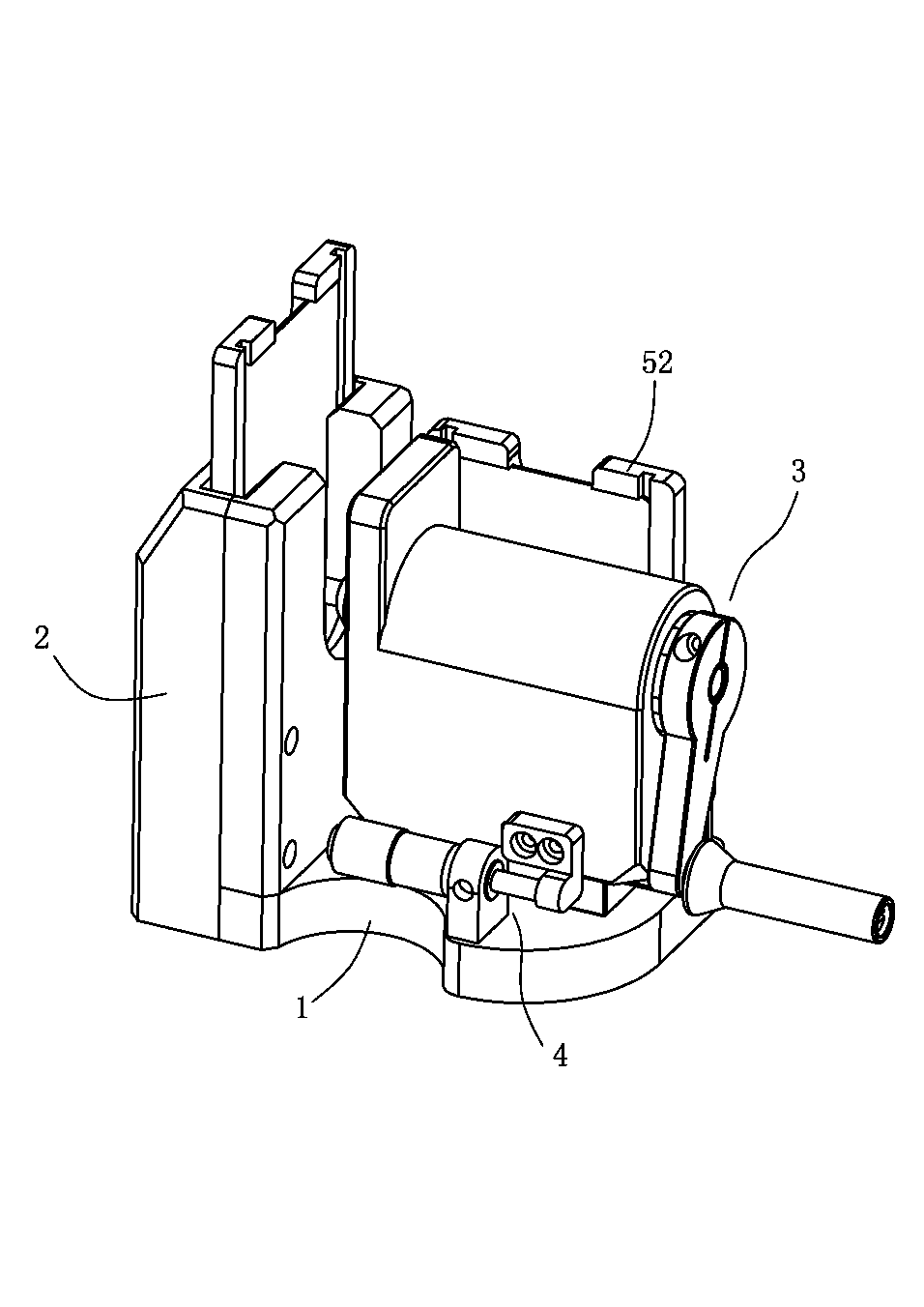

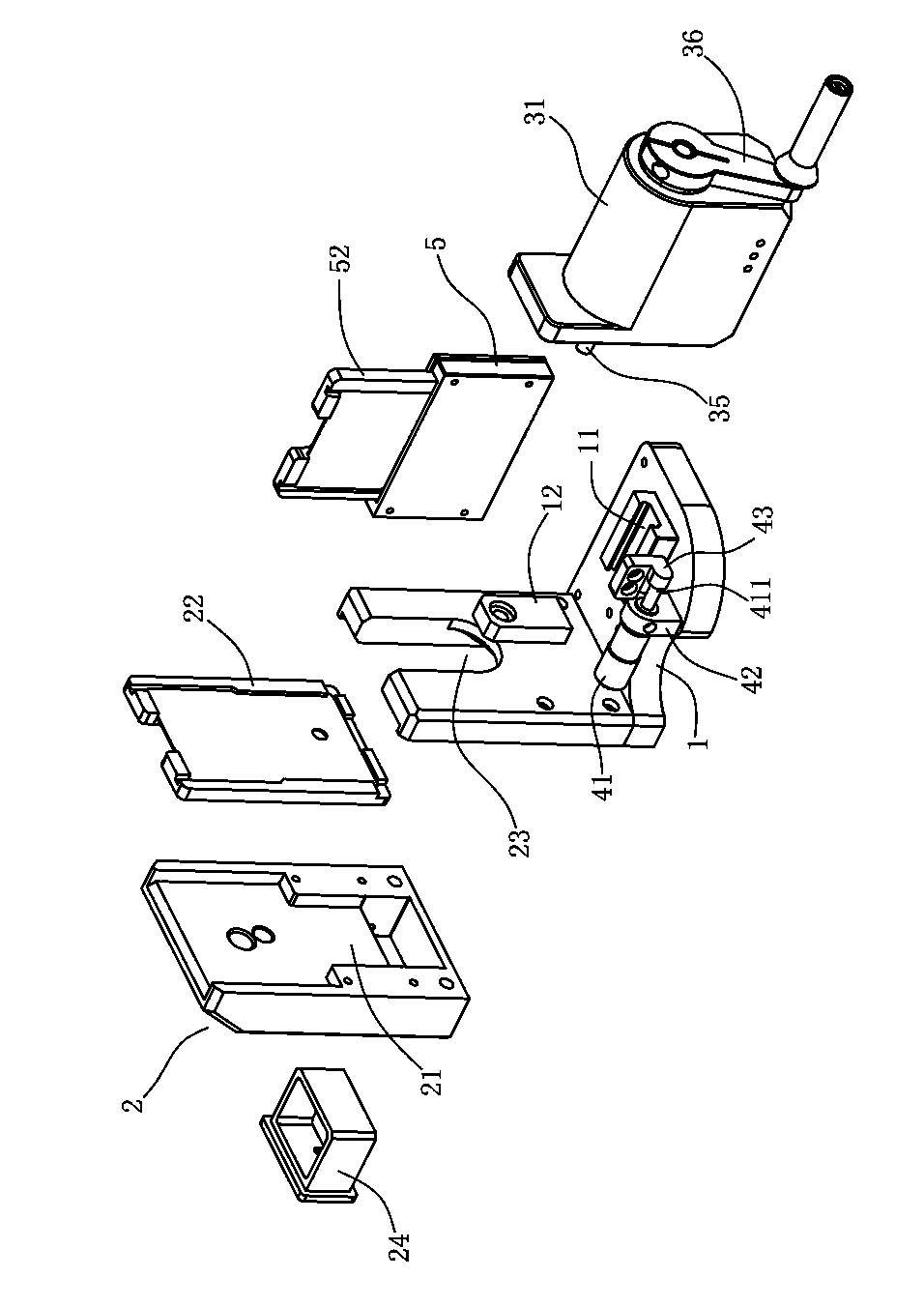

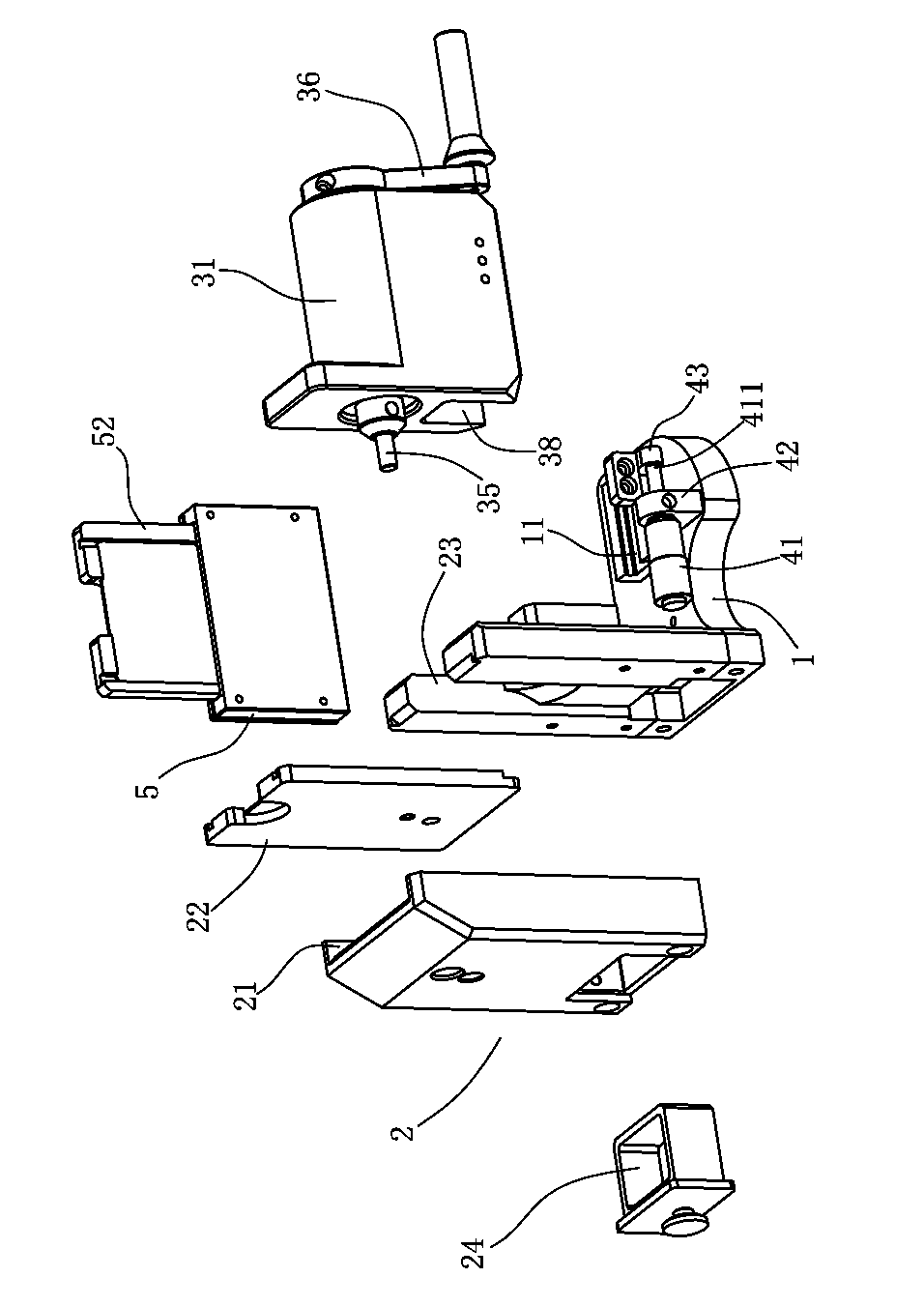

[0029] Example 1: Figure 1 to Figure 4 An embodiment of the present invention is shown. A card drilling fixture of the present invention includes a base 1, which also includes a first card positioning seat 2, a drilling device 3, and an adjusting device 4. The drilling device 3 It is slidably arranged on the base 1, the first card positioning seat 2 is arranged directly in front of the drilling device 3, and the adjusting device 4 is arranged on the base 1 and fixedly connected with the drilling device 3.

[0030] The drilling device 3 includes a drilling body 31. The drilling body 31 is provided with a through hole 32 passing through the front and rear ends thereof. A drill rod 34 is fixed in the through hole 32 through a bearing 33. The front end of the drill rod 34 A milling cutter 35 is detachably provided, and a drilling handle 36 is fixed at the rear end of the drill rod 34.

[0031] A sliding block 37 is fixed at the bottom of the drilling body 31, and a sliding groove 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com