Water filtering pipe, underground water monitoring well device and construction method

A technology for groundwater and water filter pipes, which is applied in the field of new water filter pipes and groundwater monitoring well devices. It can solve the problems of adverse effects of subsequent use of the site, short working hours, and high cost of well construction, so as to save materials and transportation labor costs and reduce groundwater disturbance. , The effect of simplifying the well construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

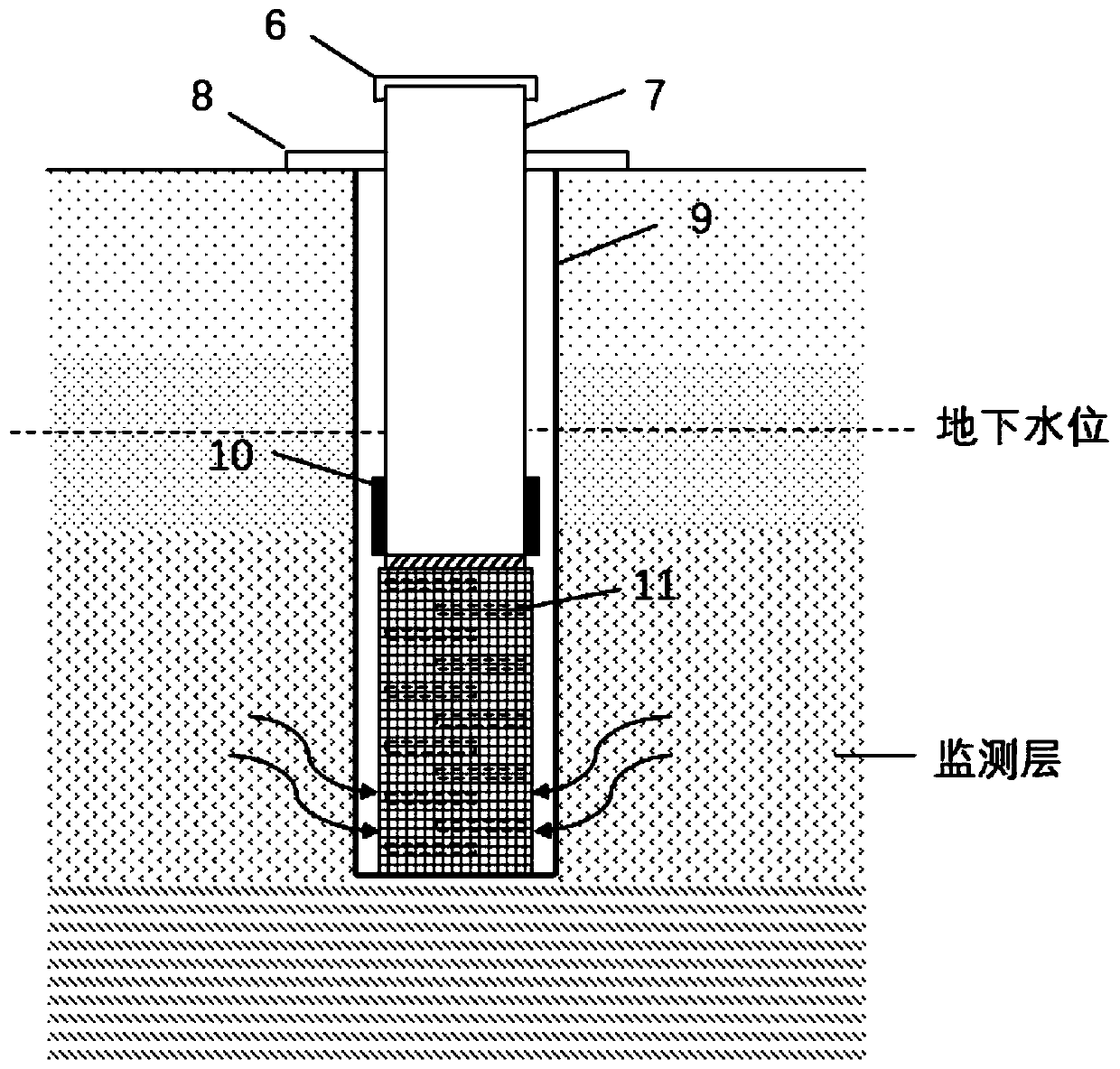

[0031] The groundwater monitoring well device is used to be installed in the groundwater sampling well, and after filtering the groundwater in a specific formation, the groundwater in a specific formation that needs to be monitored is obtained.

[0032] like figure 1 As shown, the groundwater monitoring well device includes a plurality of tubular well pipes 7 , filter pipes 11 , water stop rings 10 , wellhead protection covers 6 , and sampling well covers 8 connected sequentially from top to bottom.

[0033] The well pipe 7 is cylindrical, and its outer diameter is smaller than the inner diameter of the groundwater sampling well. Two adjacent well pipes 7 are connected by threaded connection or buckle connection. In the embodiment, the well pipe 7 is made of PVC material. 3 A section of about one meter, using threaded connection. When threaded connection is adopted, the upper end of the well pipe 7 is provided with an internal thread, and the outer diameter of the connection ...

Embodiment 2

[0073] The other structures of this embodiment are the same as those of the first embodiment, except that the body structure of the filter pipe is different from that of the first embodiment.

[0074] In this embodiment, the tube body is a cylindrical tube body with a tube wall, and a plurality of through holes are arranged on the tube wall, and the bottom of the tube body may or may not be closed. In an embodiment, the bottom of the tube is closed.

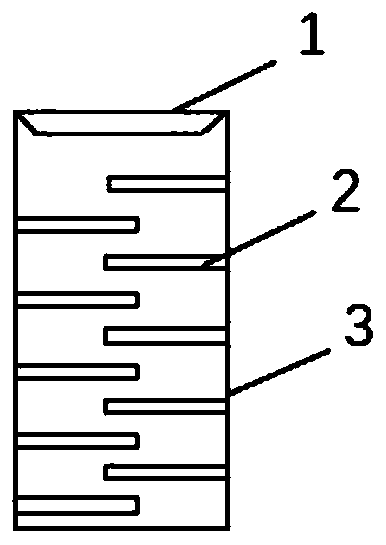

[0075] Wherein, the pipe wall includes an upper wall part, a middle wall part and a lower wall part from top to bottom,

[0076] The plurality of through holes include an upper through hole disposed on the upper wall portion, a middle through hole disposed on the middle wall portion, and a lower through hole disposed on the lower wall portion.

[0077] The angle between the centerline of the upper through hole and the downward direction of the centerline of the pipe body is an acute angle.

[0078] The centerline of the through...

Embodiment 3

[0081] The other structures of this embodiment are the same as those of the first embodiment, except that the structure of the filter pipe and the installation position of the water stop ring are different from those of the first embodiment.

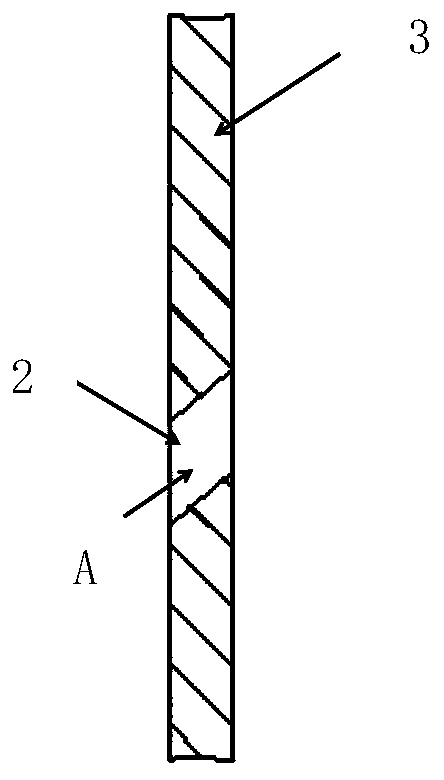

[0082] The water filter pipe includes a pipe body, at least one filter layer and a water stop ring.

[0083] The cylindrical pipe body has a pipe wall, including an upper part of the pipe wall and a lower part of the pipe wall, and the lower part of the pipe wall is provided with a plurality of through holes;

[0084] At least one filter layer is wrapped around the lower part of the pipe wall;

[0085] The water stop ring is arranged around the upper part of the pipe wall and is located between the well pipe 7 and the well wall of the sampling well.

[0086] Wherein, the center line of the through hole is perpendicular to the center line of the pipe body,

[0087] Alternatively, the downward angle between the centerline of the through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com