A kind of anti-floating anchor construction method

A technology of anti-floating anchor rods and construction methods, which is applied in the direction of basic structure engineering, buildings, sheet pile walls, etc., can solve the problems of difficult and easy construction quality assurance, low economic benefits, slow construction speed, etc., to achieve safe and civilized construction, reduce Effects of pollution and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

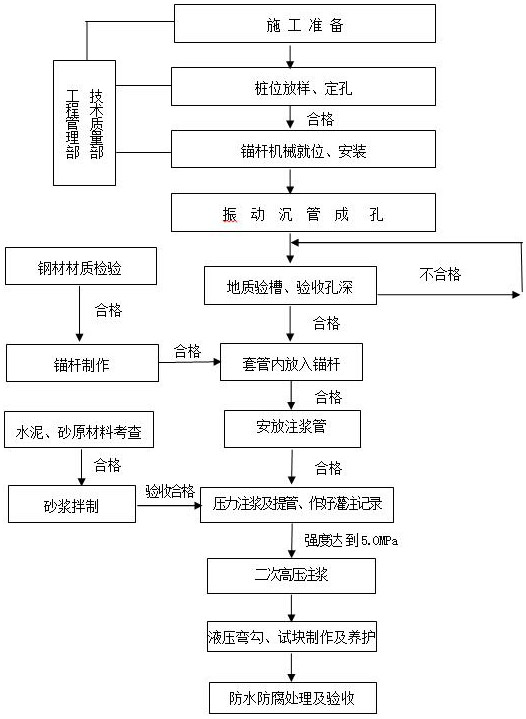

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be further described in conjunction with specific embodiments, but the examples do not limit the present invention in any form. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field. Unless otherwise specified, the reagents and materials used in the following examples are commercially available.

[0037] The following table 1 and table 2 show the main materials and main equipment used in the implementation of the construction method of the following examples:.

[0038] Table 1 Main material equipment list

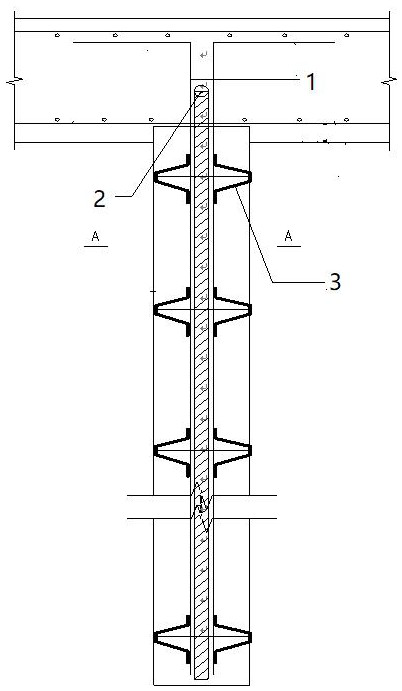

[0039] serial number Name Types of Remark 1 cement P.042.5 Raw materials for primary and secondary grouting 2 rebar Grade 3 steel 22 and Grade 3 steel 10 Raw materials for making anchor rods and locators. 3 sand Middle sand Raw material for primary grouting. 4 Grouting ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com