Prefabricated high-pressure airbag isolation pile structure with grouting function and construction method

A technology for isolating piles and airbags, which is used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problem that the direction of the grout and the corresponding reinforcement area cannot be accurately determined, there are many uncontrollable factors in the grouting reinforcement method, and the deformation of surrounding structures is increased. and other problems, to achieve the effect of compensating for displacement deformation, reducing displacement, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

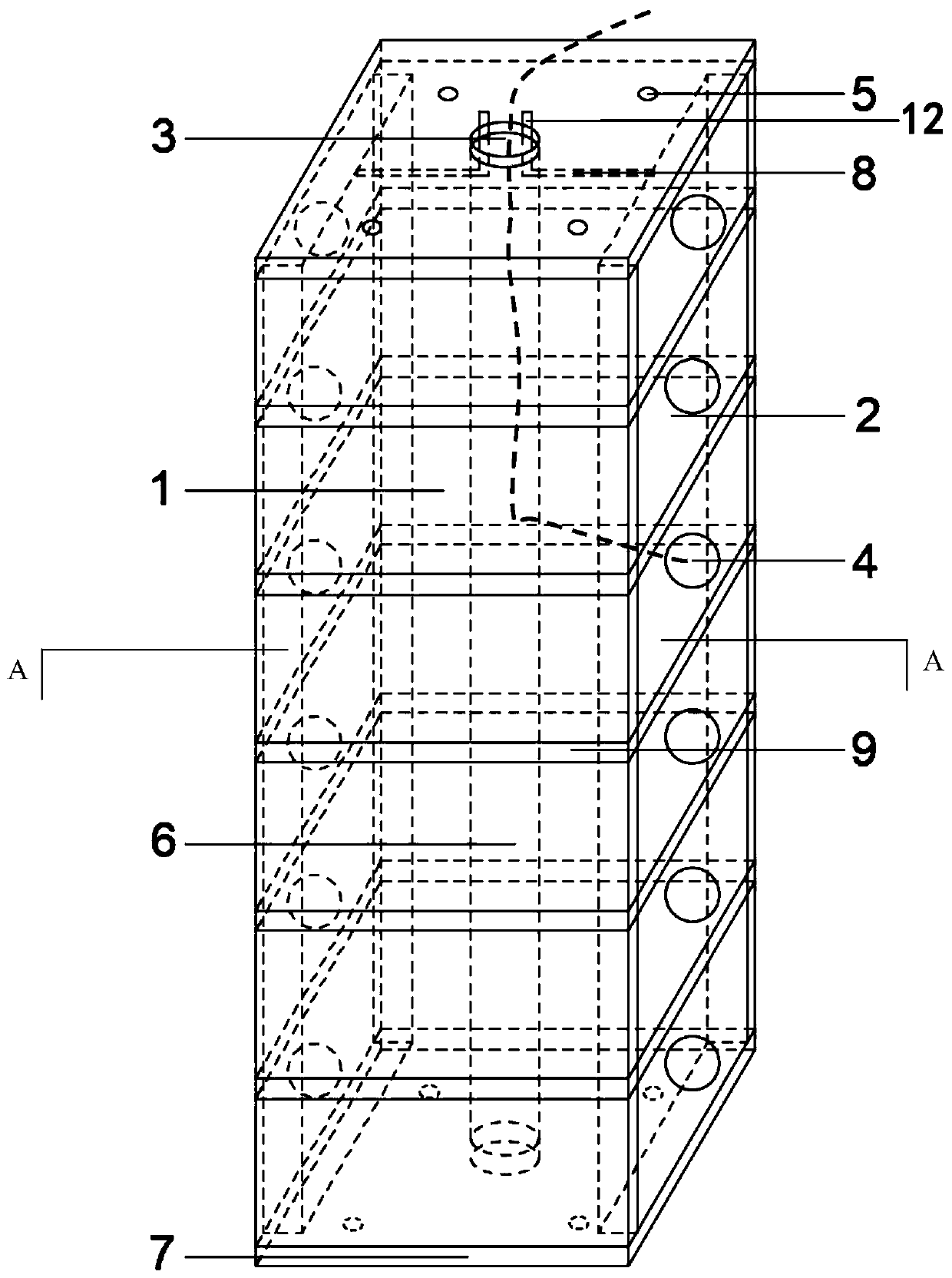

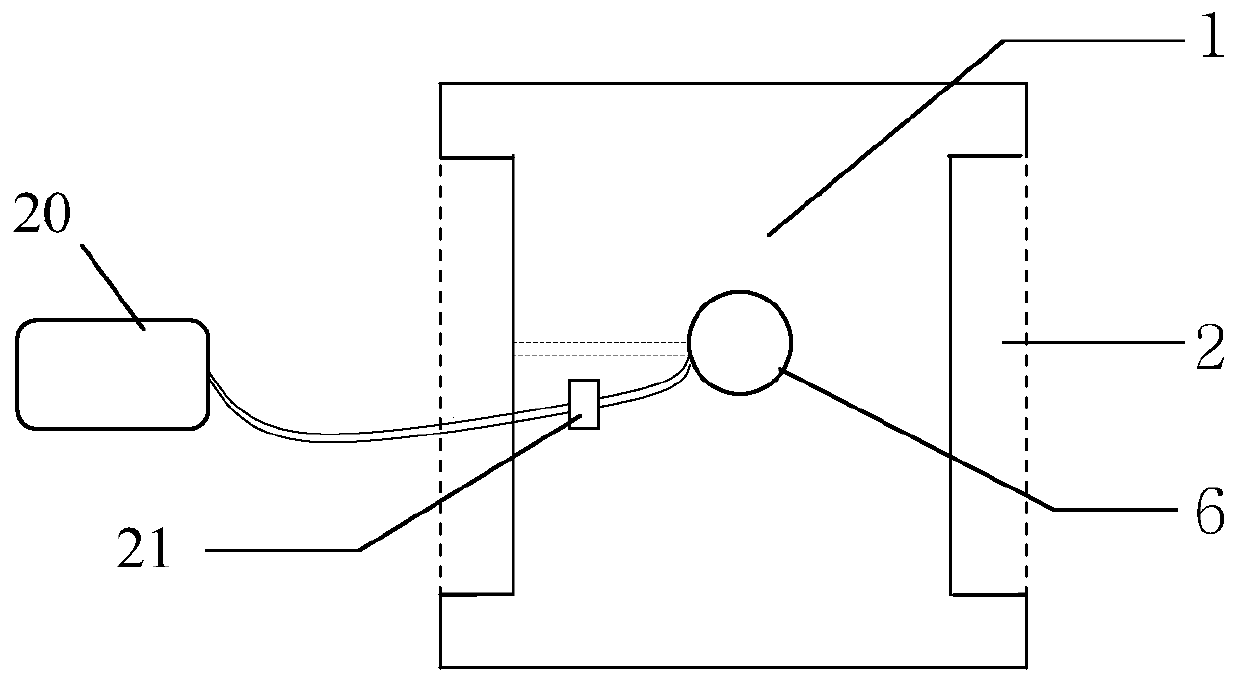

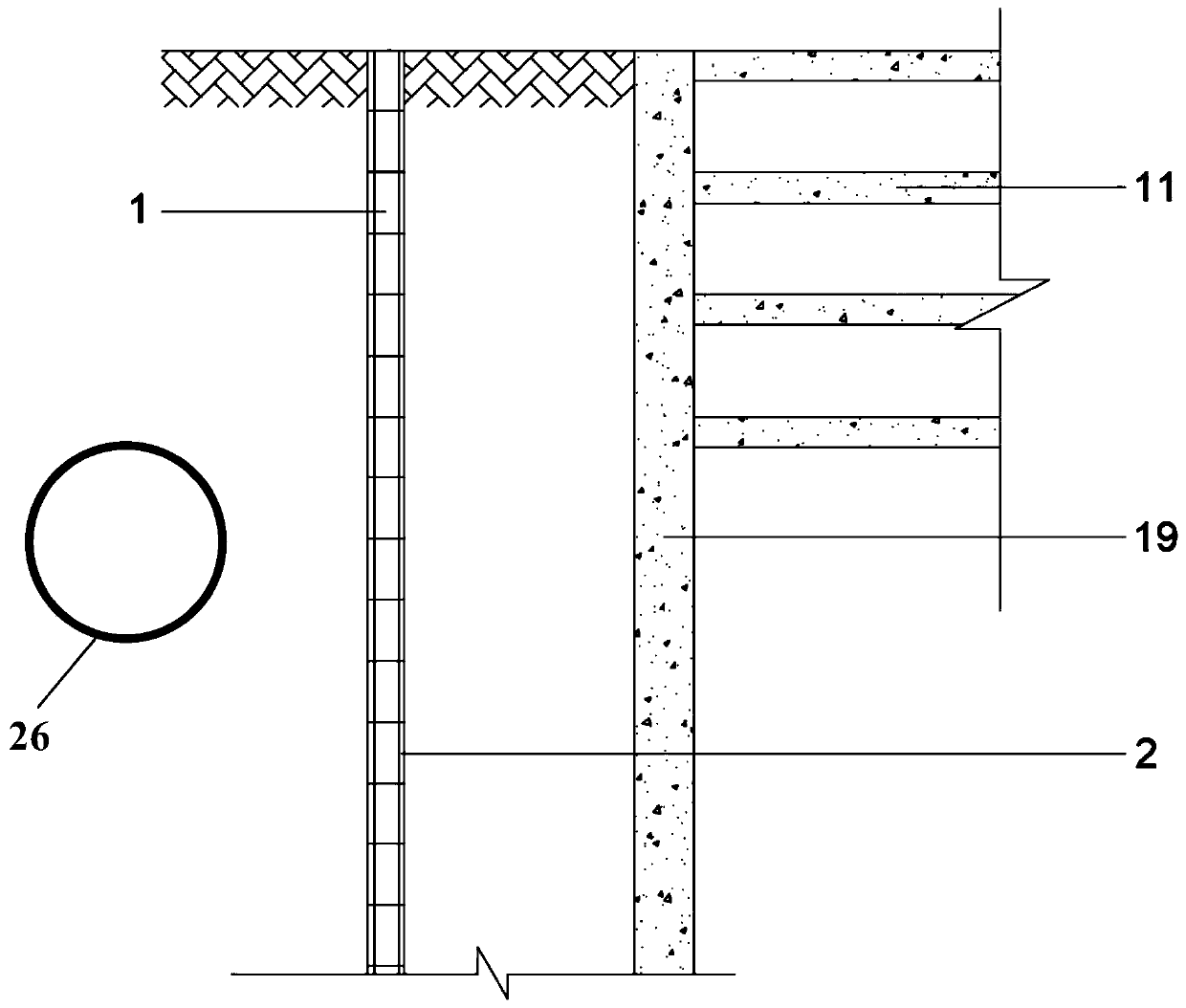

[0032] The prefabricated high-pressure airbag isolation pile structure with grouting function includes a prefabricated high-pressure airbag pile body 1, an automatic control system 10 and a grouting system. The grouting system is mainly composed of a grouting valve 21 and a grouting pump 20 . The prefabricated high-pressure air bag pile body 1 is the core design of the present invention, the pile body can adopt reinforced concrete, and the section can be designed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com