Drainage control method of washing machine

A control method and washing machine technology, which are applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of troubled designers, increase of rotating barrels, limited position, etc., to achieve good washing effect, realize expansion effect, and save washing. The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 1 As shown, the drainage control method of a washing machine in this embodiment, the washing machine includes a washing bucket that can be used to hold water during the washing process and a water collecting device for collecting the water discharged from the washing bucket, and the washing bucket of the washing machine in this embodiment is used as a water bucket , the outside of the washing bucket is no longer provided with an outer bucket. In this embodiment, only a water collection device is provided at the bottom of the washing bucket. The water collection device generally has a straight drainage pipeline, but when the drainage speed slows down due to poor drainage , causing the water level in the water collecting ring to be too high, and there is a risk of overflow.

[0045] Therefore, the water collecting device described in this embodiment is equipped with a collecting water level detection device, and combined with a drainage control method to pr...

Embodiment 2

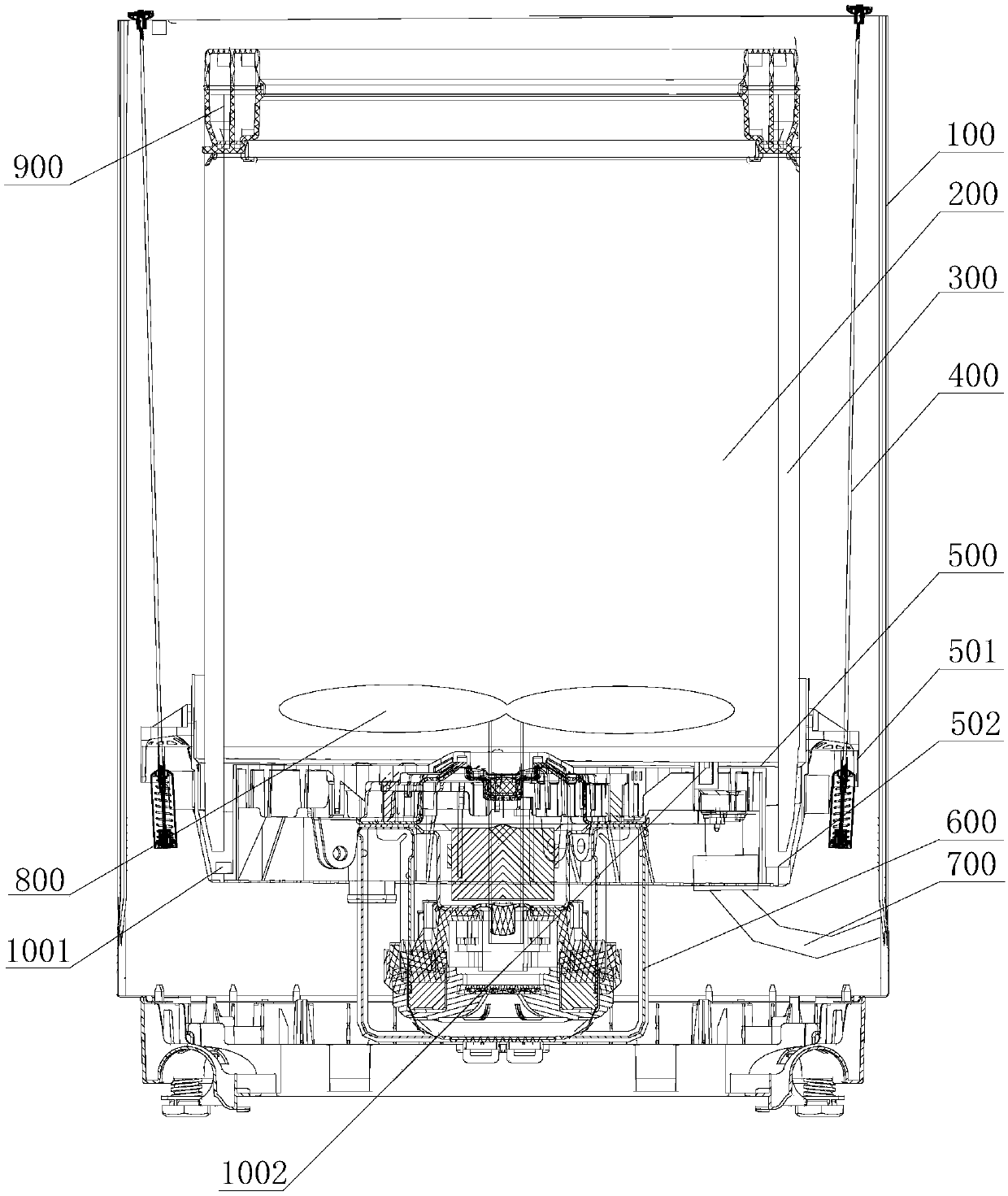

[0064] Such as figure 2 As shown, a washing machine includes a water level detection device, a washing tub 200 that can be used to hold water during the washing process, and a water collection device 500 for collecting the water discharged from the washing tub. The water level detection device includes a washing tub 200 for detecting The washing water level detection device 1002 for the inner water level and the water collection level detection device 1001 for detecting the water level in the water collection device 500 .

[0065] The washing tub 200 of the washing machine in this embodiment is used as a water bucket, and the outer tub is no longer provided outside the washing tub 200. In this embodiment, only a water collecting device 500 is provided at the bottom of the washing tub 200. The water level detection device of this embodiment includes a water level detection device for detecting washing The washing water level detection device 1002 of the water level in the buck...

Embodiment 3

[0076] Such as Figure 2-Figure 5 As shown, a washing machine in this embodiment includes a washing tub 200 for holding water during the washing process and a water collecting device 500 for collecting water discharged from the washing tub 200. The water collecting device 500 includes a water collecting chamber 503 The drain port 504 communicates with the water collection chamber 503 , and the bottom wall of the water collection chamber 503 is provided with a water guide structure for guiding water flow to the drain port 504 .

[0077] The washing tub 200 of the washing machine in this embodiment is used as a water bucket, and no outer tub is provided outside the washing tub 200. In this embodiment, only a water collecting device 500 is provided at the bottom of the washing tub 200, so that the washing water in the washing tub is discharged to the water collecting device 500, so the water collecting device 500 has a water collecting chamber 503 to realize the function of tempo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com