Variable frequency speed regulation device for vacuum carburizing process and speed regulating method thereof

A technology of variable frequency speed regulation and vacuum carburizing, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., which can solve the problem of surface carbon inhomogeneity and uniformity of carburizing layer, affecting the carburizing depth of workpiece surface, fan There are no problems such as speed regulation function, and the effect of uniform carburizing, reduced deformation, uniform atmosphere and temperature is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

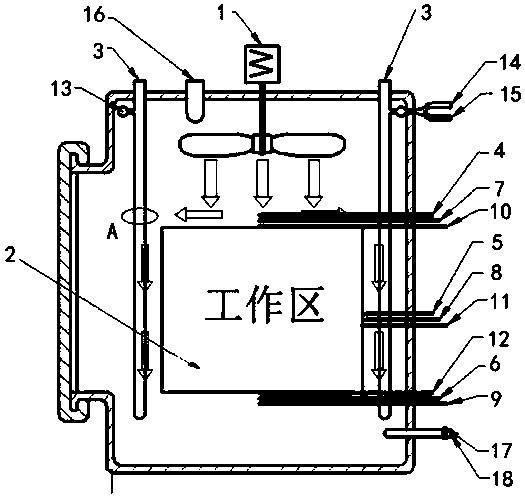

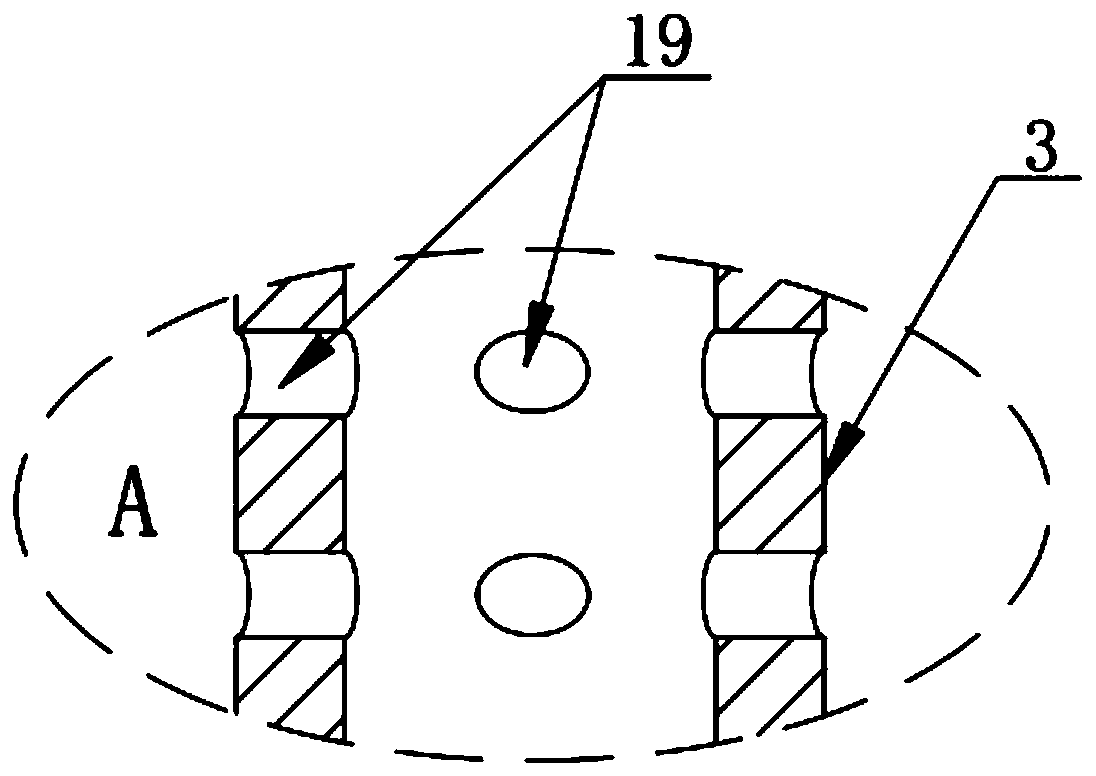

[0042] refer to figure 1 As shown, there is provided a frequency conversion speed regulating device for the vacuum carburizing process, including a vacuum carburizing furnace and some radiant tubes 3 extending into the furnace from the outside of the furnace and uniformly distributed around the working area 2 in the furnace, and also including: A variable frequency speed regulating fan 1 arranged on the top of the vacuum carburizing furnace; a first thermocouple arranged at the top, side and lower center of the working area 2 for detecting the temperature at the corresponding position of the working area 2 4. The second thermocouple 5 and the third thermocouple 6; one by one are arranged on the upper surface, the side surface and the center of the lower surface of the working area 2 to detect the first heat conduction of the furnace gas atmosphere in the corresponding position of the working area 2 Probe 7, second heat conduction probe 8 and third heat conduction probe 9; Fou...

Embodiment 2

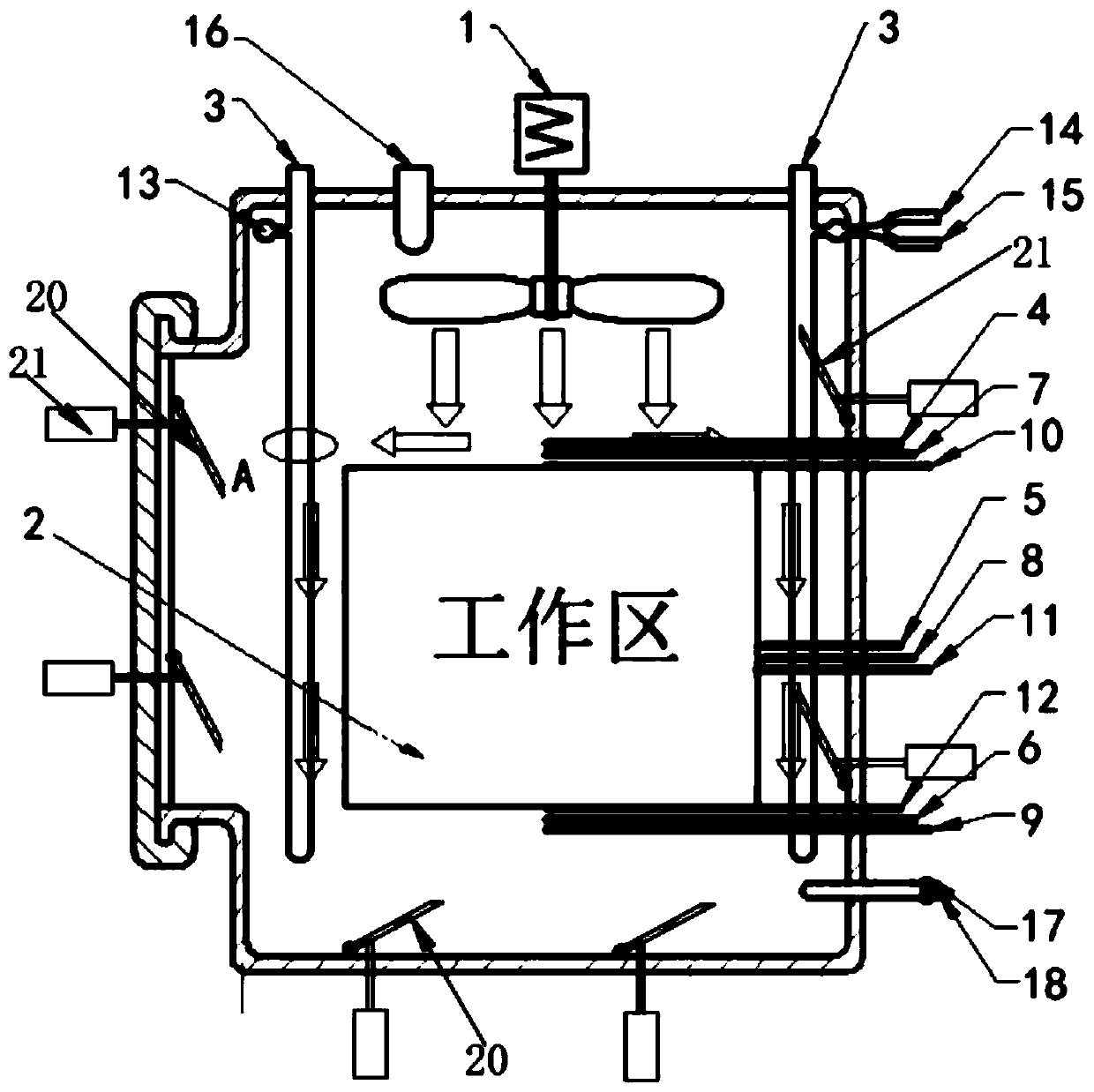

[0053] Different from Example 1, see image 3 As shown, in this embodiment, the side wall and the bottom of the vacuum carburizing furnace are respectively hingedly provided with several adjustable baffles 20, and the adjustable baffles 20 are connected with the telescopic motor arranged on the outer wall of the vacuum carburizing furnace. 21 connections. An adjustable baffle 20 is arranged at a certain position in the furnace, through which the atmosphere in the furnace can flow according to the set channel when flowing, so that the atmosphere in the furnace is uniform and the occurrence of dead ends is avoided. The installation position and angle of the adjustable baffle 20 can be changed according to the needs of the fluid movement, combined with the frequency conversion speed regulation of the frequency conversion speed regulation fan 1, the uniformity of carburizing on the surface of the workpiece can be ensured.

Embodiment 3

[0055] refer to Figure 4 As shown, based on the frequency conversion speed regulation device for the vacuum carburizing process provided by the above-mentioned embodiment 1 or embodiment 2, this embodiment provides a frequency conversion speed regulation method for the vacuum carburization process as described above, Including the following steps:

[0056] S1, in the heating stage, the speed of the heating process is regulated according to the temperature signals of each part of the working area and the temperature of the radiant tube; by adjusting the speed of the frequency conversion speed regulating fan 1, the temperature difference in the heating process of each part of the working area is reduced, and the working area of the heat treatment furnace is realized. Uniform heating;

[0057] S2, after entering the carburizing stage, the speed is regulated according to the temperature difference of each part of the working area in the furnace and the atmosphere concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com