Hydraulic-driving type miniature tapered hole inner surface cavitation shot-blasting system and method

A driving type, inner surface technology, applied in the fields of shot peening, cavitation generation and processing, to achieve the effect of strong versatility, improved comprehensive performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

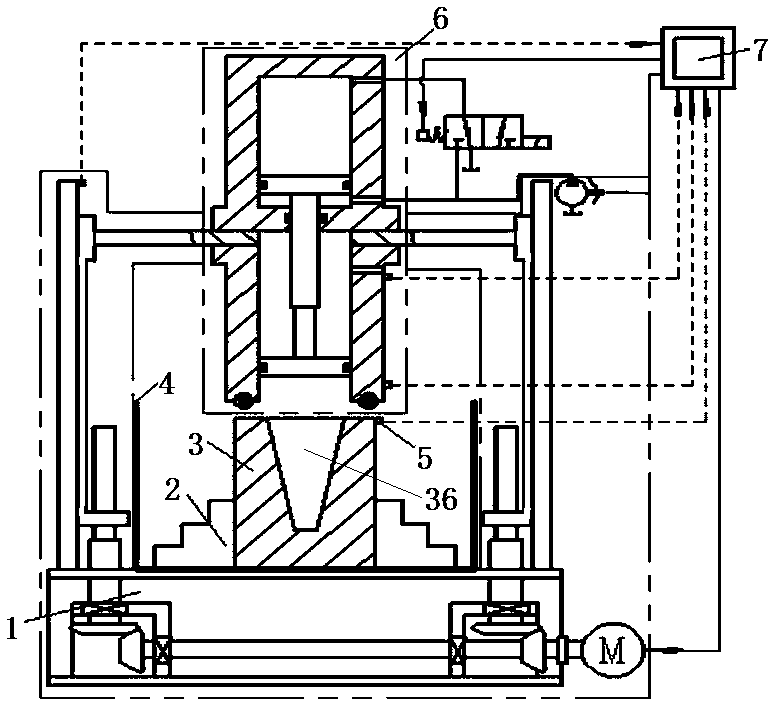

[0019] Such as figure 1 As shown, a hydraulically driven micro cone inner surface cavitation shot peening system of the present invention includes a driving device 1 , an oil tank 4 , a four-jaw chuck 2 , a hydraulic piston moving device 6 , a position sensor and a control terminal 7 .

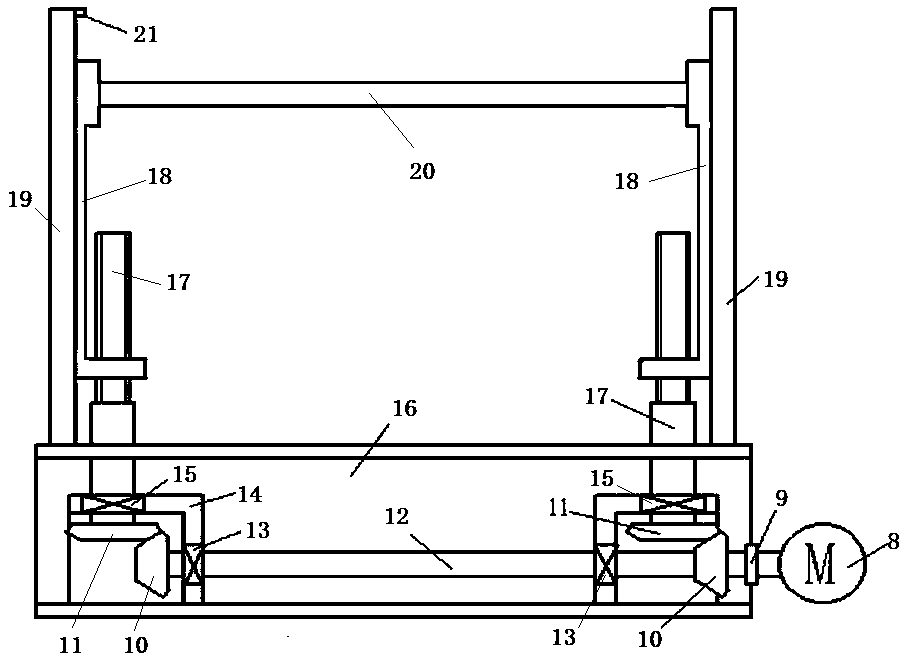

[0020] see you again figure 2 , the driving device 1 includes a worktable 16, a motor 8, a coupling 9, a connecting rod 12, a first bearing 13, a second bearing 15, a trihedron 14, a first bevel gear 10, a second bevel gear 11, and a screw 17 , guide rail 19, slider 18 and cover plate 20. Two trihedrons 14 are fixedly connected to the workbench 16, and the two trihedrons 14 are symmetrically arranged face to face. Each trihedron 14 is composed of two vertical planes and a horizontal plane, and one of the vertical planes is fixedly connected to the workbench 16 by screws. , the other vertical surface is connected to one end of the horizontal connecting rod 12 through the first bearing 13, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com