Modified chlorinated paraffin, preparation method and application thereof

A chlorinated paraffin, modification technology, applied in the field of modified chlorinated paraffin and its preparation, can solve the problems of increasing the plasticizing effect of chlorinated paraffin, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

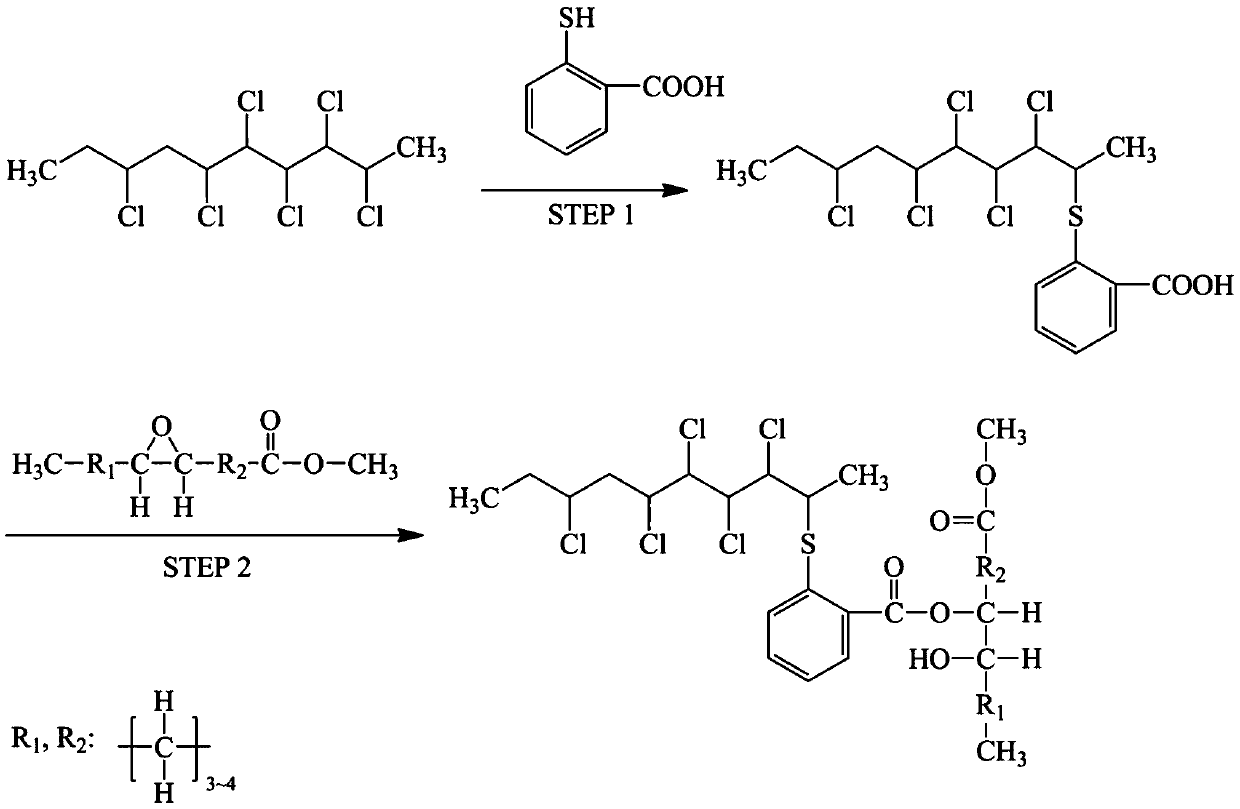

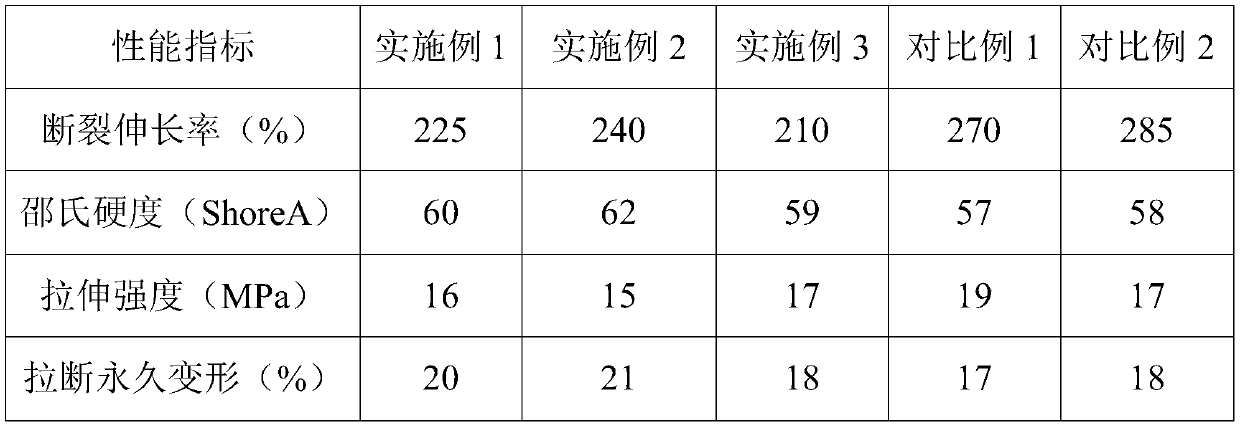

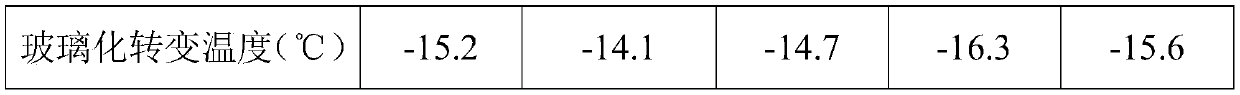

[0023] A preparation method of modified chlorinated paraffin, comprising the steps of:

[0024] S1. Dissolve 1 part of chlorinated paraffin in 10 parts of acetone by weight. After the chlorinated paraffin is completely dissolved, add 1 part of thiosalicylic acid and 2 parts of potassium carbonate, and react at a temperature of 90°C under nitrogen protection. After 24 hours, after the reaction is completed, pour the reactant into 10 parts of ethanol / water (the volume ratio of ethanol and water is 2:1) mixed solution, and dry in vacuum for 2 hours to obtain a transparent liquid;

[0025] S2. Dissolving the above transparent liquid in 10 parts of tetrahydrofuran, adjusting the pH value to 4 with hydrochloric acid, then pouring into 10 parts of ethanol for extraction, and drying in vacuum for 2 hours to obtain a transparent liquid thiosalicylic acid modified chlorinated paraffin product;

[0026] S3. Add 1 part of thiosalicylic acid-modified chlorinated paraffin product to 10 part...

Embodiment 2

[0028] A preparation method of modified chlorinated paraffin, comprising the steps of:

[0029] S1. Take 2 parts by weight of chlorinated paraffin and dissolve in 15 parts of acetone. After the chlorinated paraffin is completely dissolved, add 2 parts of thiosalicylic acid and 2 parts of potassium carbonate, and react at a temperature of 70°C under nitrogen protection. After 24 hours, after the reaction is completed, the reactant is poured into 15 parts by weight of ethanol / water (the volume ratio of ethanol and water is 2:1) mixed solution, and vacuum-dried for 2 hours to obtain a transparent liquid;

[0030] S2. Dissolving the above transparent liquid in 15 parts of tetrahydrofuran, adjusting the pH value to 4 with hydrochloric acid, pouring into 10 parts of ethanol for extraction, and drying in vacuum for 2 hours to obtain a transparent liquid thiosalicylic acid-modified chlorinated paraffin product;

[0031] S3. Add 2 parts of thiosalicylic acid-modified chlorinated paraff...

Embodiment 3

[0033] A preparation method of modified chlorinated paraffin, comprising the steps of:

[0034] S1. Take 2 parts by weight of chlorinated paraffin and dissolve in 20 parts of acetone. After the chlorinated paraffin is completely dissolved, add 2 parts of thiosalicylic acid and 2 parts of potassium carbonate, and react at a temperature of 70°C under nitrogen protection. 24h, after the reaction is completed, the reactant is poured into 20 parts of ethanol / water (the volume ratio of ethanol and water is 2:1) mixed solution, and vacuum-dried for 2h to obtain a transparent liquid;

[0035] S2. Dissolving the above transparent liquid in 20 parts of tetrahydrofuran, adjusting the pH value to 4 with hydrochloric acid, pouring into 20 parts of ethanol for extraction, and drying in vacuum for 2 hours to obtain a transparent liquid thiosalicylic acid-modified chlorinated paraffin product;

[0036] S3. Add 2 parts of thiosalicylic acid-modified chlorinated paraffin product to 10 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com