Deep desulfurization system and desulfurization method thereof

A deep desulfurization and desulfurization agent technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, etc., can solve the problems affecting product quality and the activity decline of hydrodesulfurization catalysts, so as to improve production adaptability and adaptability, The effect of improving product indicators and reducing the requirements for raw material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

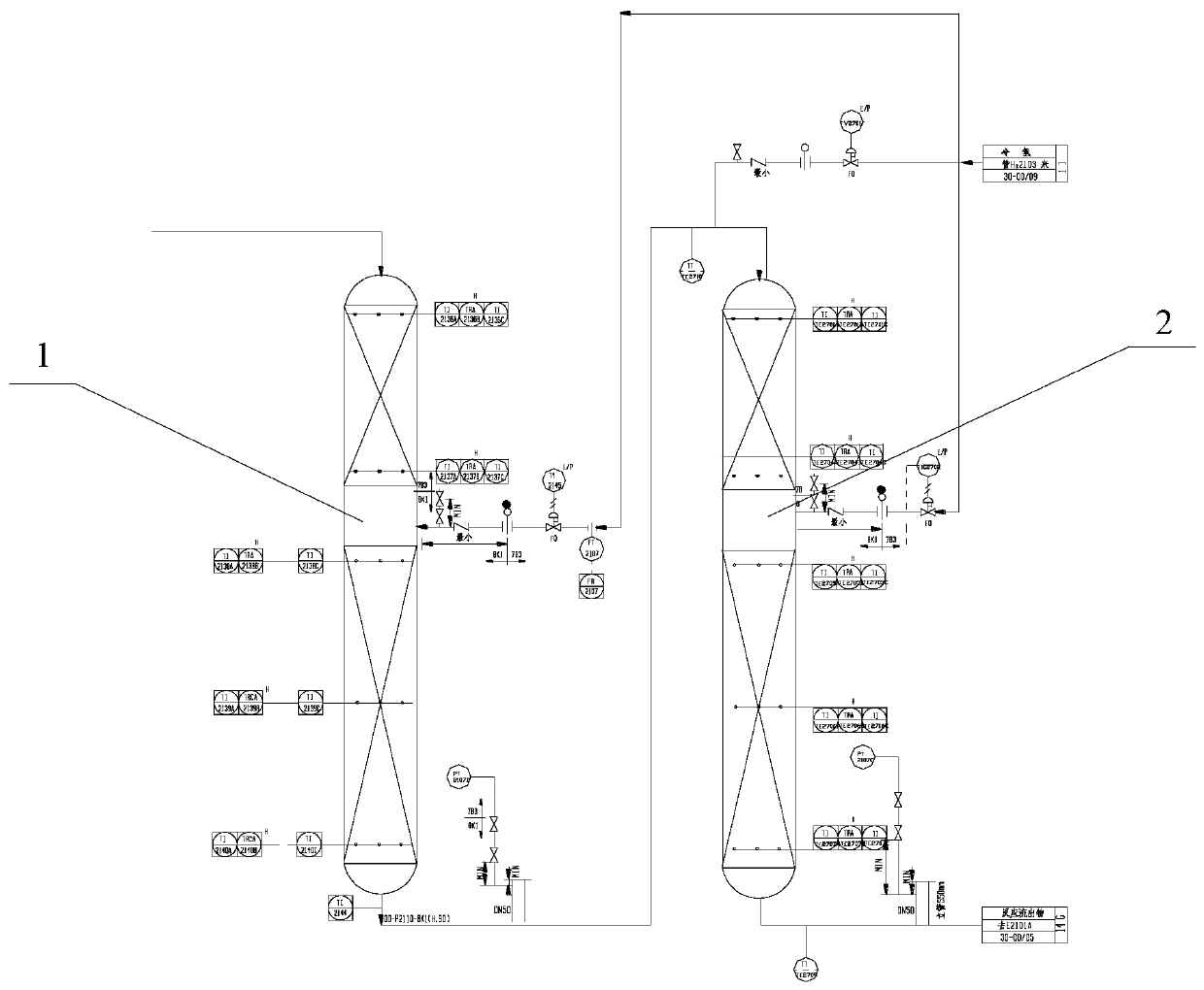

[0025] Example: A deep desulfurization system includes a first hydrogenation reactor 1 and a second hydrogenation reactor 2 connected by pipelines.

[0026] The first hydrogenation reactor 1 and the second hydrogenation reactor 2 both have two catalyst beds; wherein:

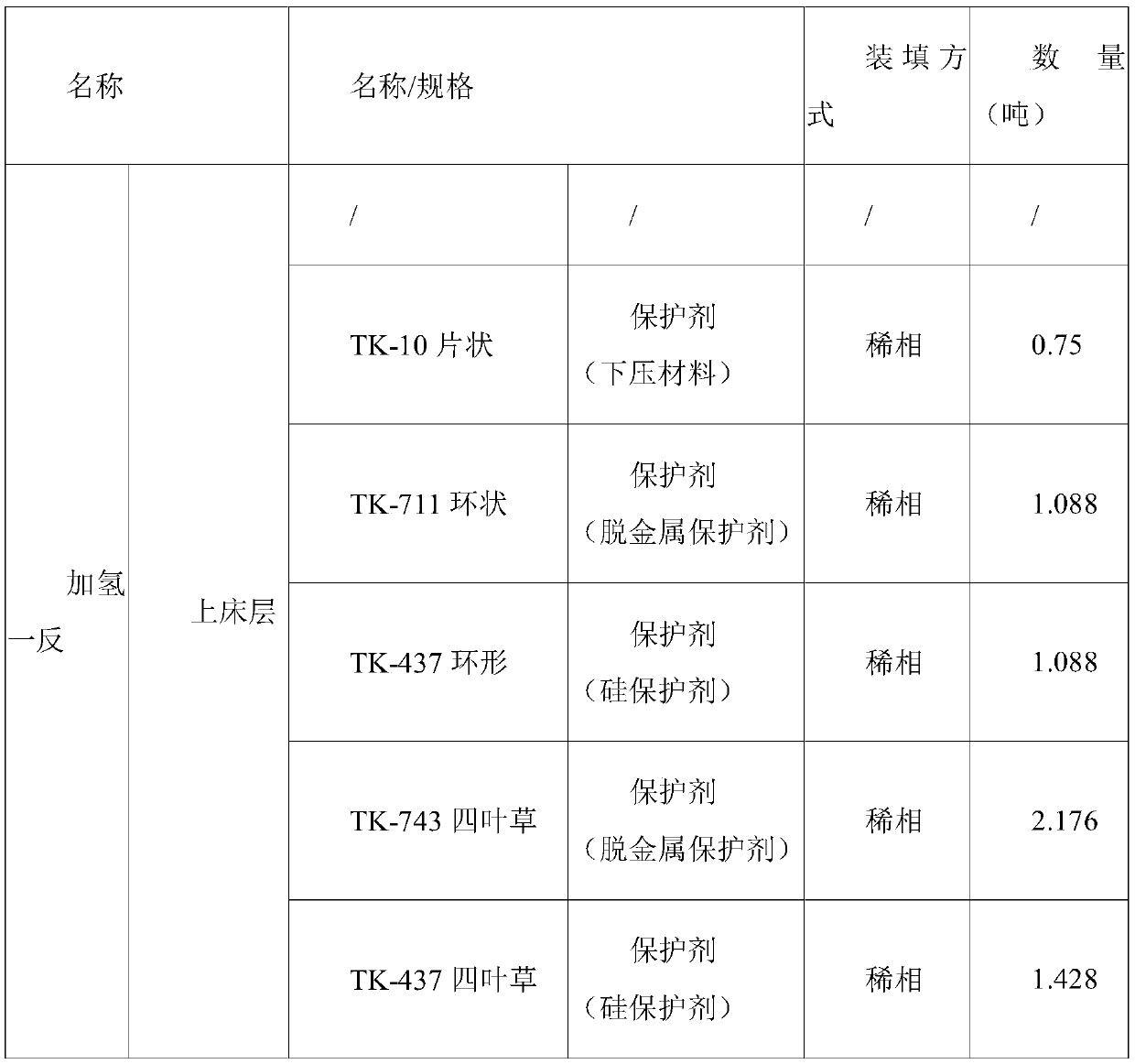

[0027] The upper catalyst bed of the first hydrogenation reactor 1 includes dense-phase desulfurization / dearomatization catalyst TK-568, and dilute phase sheet-shaped compacted top catalyst TK-10, cyclic demetalization protective agent TK-711, Ring-shaped silicon protective agent TK-437, four-leaf clover shaped demetallic protective agent TK-743, four-leaf clover shaped silicon protective agent TK-437, 3mm porcelain balls, 6mm porcelain balls and 13mm porcelain balls.

[0028] The lower catalyst bed of the first hydrogenation reactor 1 includes dense-phase desulfurization / dearomatization catalyst TK-568, and dilute phase 3mm ceramic balls, 6mm ceramic balls, 13mm ceramic balls and 15mm ceramic balls.

[0029] The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com