Large-particle-diameter coal pyrolysis and separation utilization production system

A production system, large particle size technology, applied in the directions of dispersed particle separation, separation method, solid separation, etc., can solve the problems of weak practicability, ecological environment damage, inconvenient use, etc., to improve practicability and improve contact effect. , the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

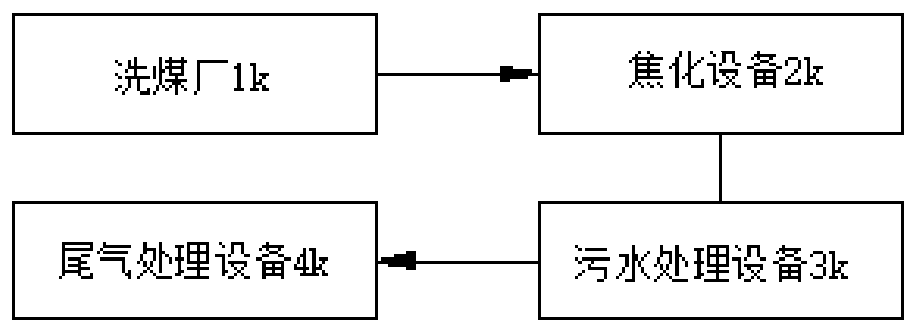

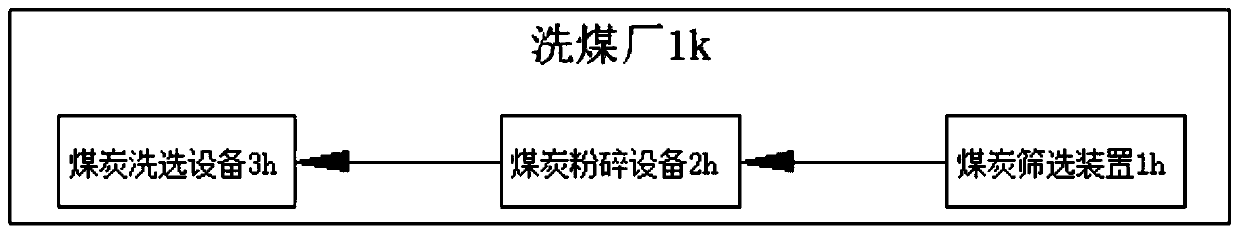

[0044] The particle size coal cracking and quality separation production system includes: coal washing plant 1k, coking equipment 2k, sewage treatment equipment 3k and tail gas treatment equipment 4k, the coal washing plant 1k is connected to the coking equipment 2k, and the coking equipment 2k is connected to the coking equipment 2k The sewage treatment equipment 3k is connected, and the sewage treatment equipment 3k is connected with the tail gas treatment equipment 4k.

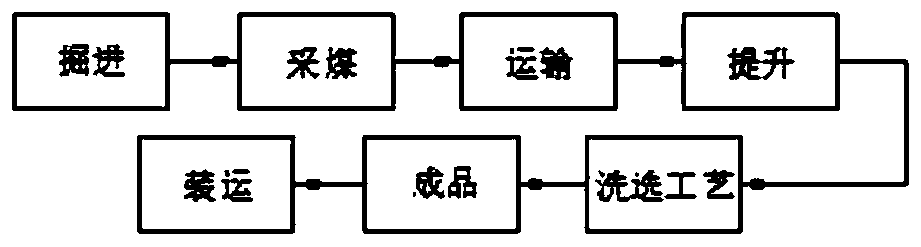

[0045] The coal washing plant 1k includes the following steps: the first step: excavating a part of the section as a pilot tunnel, and then enlarging the entire section of the excavated tunnel successively, using jack picks, combined machines and other methods to excavate; the second step: mining Coal, the valuable coal is excavated from the ground through the coal mining machine, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com