Preparation method of soil-based gelatinized starch composite water retention material for preservation of soil moisture

A technology of water-retaining material and starch, which is applied in the preparation of soil-based starch composite water-retaining materials and the preparation of soil-based gelatinized starch composite water-retaining materials, which can solve the problems of refractory degradation, white pollution of plastic film, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

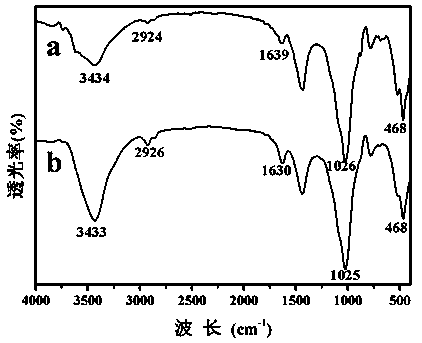

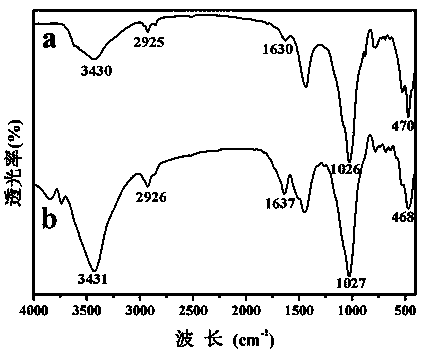

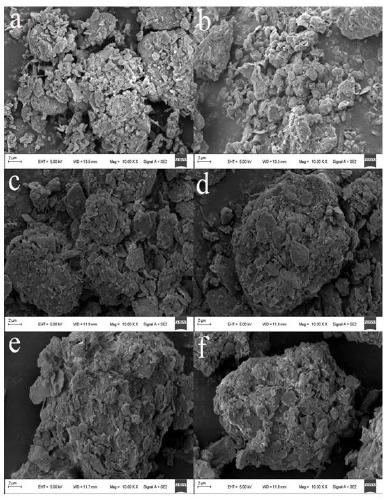

Image

Examples

Embodiment 1

[0039] Embodiment one, the preparation of soil-based gelatinized potato starch composite material

[0040] 1) After removing impurities, loess and clay are mixed at a mass ratio of 1:2, dried, crushed to 100-200 mesh, and set aside;

[0041] 2) Take 100g of potato starch, add 900g of tap water, gelatinize at 80°C for 60 minutes, then add 1000g of mixed soil, stir at room temperature at a stirring speed of 600 r / min for 60 minutes, granulate and dry , that is, soil-based gelatinized potato starch composite material.

Embodiment 2

[0042] Embodiment two, the preparation of soil-based gelatinized sweet potato starch composite material

[0043] 1) After removing impurities, loess and clay are mixed at a mass ratio of 1:2, dried, crushed to 100-200 mesh, and set aside;

[0044] 2) Take 80g of sweet potato starch, add 850g of tap water, gelatinize at 95°C for 30min, then add 1000g of mixed soil, stir at room temperature at a stirring speed of 300r / min for 120min, granulate and dry, that is Soil-based gelatinized sweet potato starch composite material was obtained.

Embodiment 3

[0045] Embodiment three, the preparation of soil-based gelatinized tapioca starch composite material

[0046] 1) After removing impurities, loess and clay are mixed at a mass ratio of 1:2, dried, crushed to 100-200 mesh, and set aside;

[0047] 2) Take 50g of tapioca starch, add 800g of tap water, gelatinize at 65°C for 60 minutes, then add 1000g of mixed soil, stir at room temperature at a stirring speed of 400 r / min for 90 minutes, granulate, and dry. The soil-based gelatinized tapioca starch composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com