Film unloading device for polyvinyl chloride (PVC) decorative film production

A film device and decorative film technology, applied in transportation and packaging, winding strips, thin material processing, etc., to achieve the effects of convenient operation, improved film unloading efficiency, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

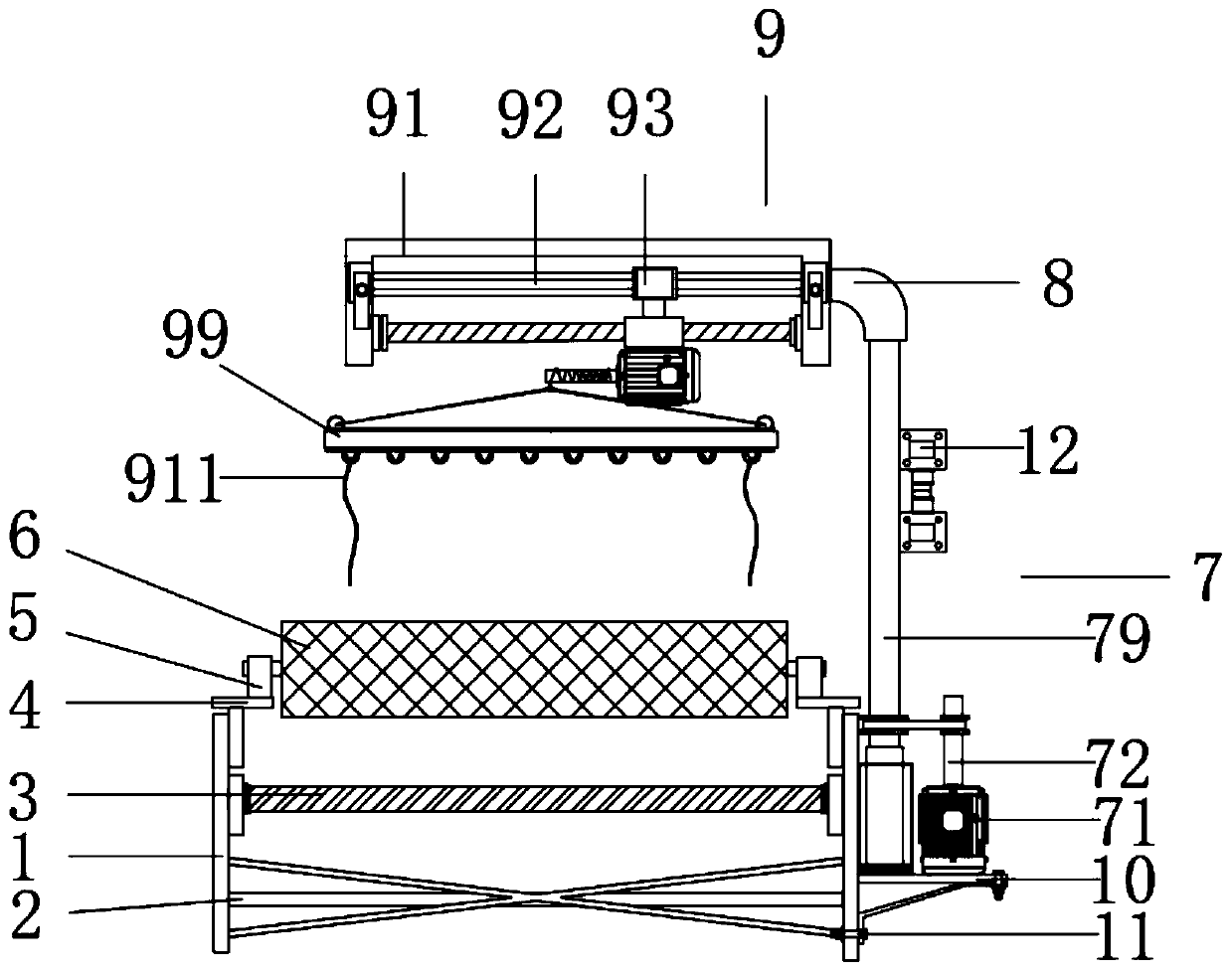

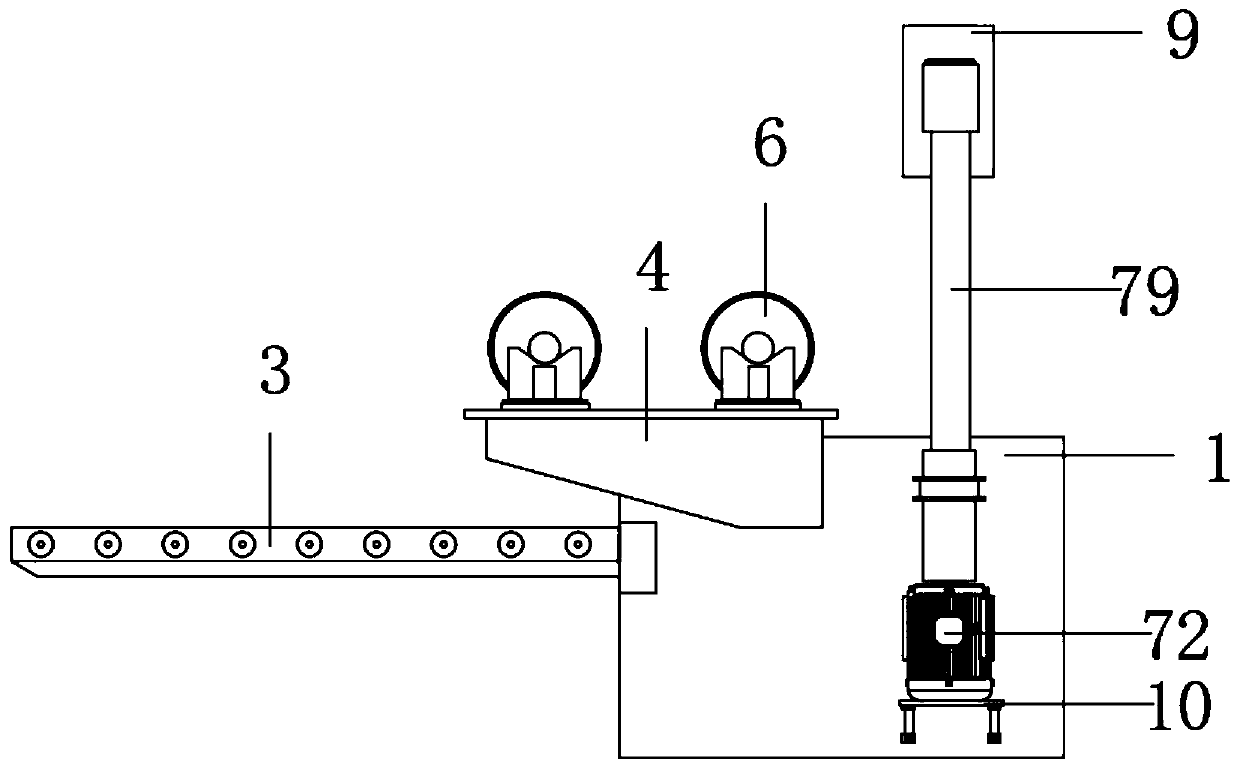

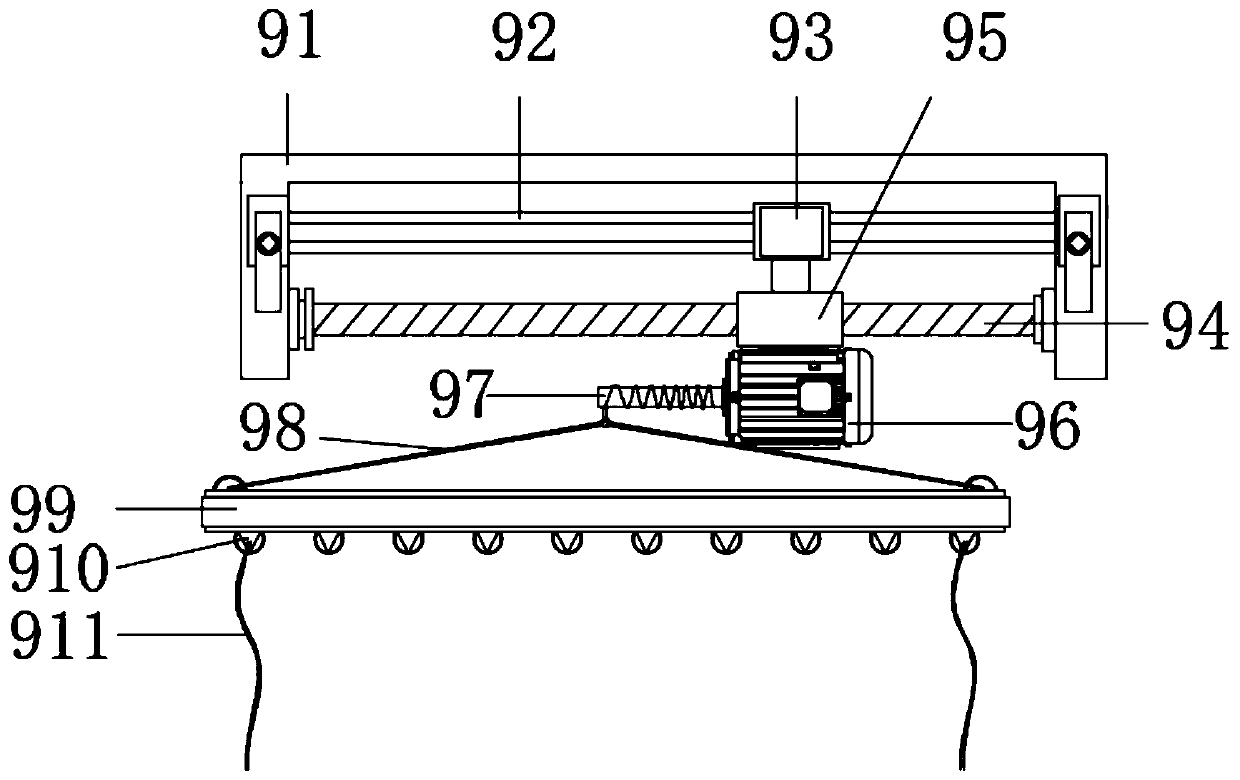

[0028] Such as Figure 1-4 As shown, the specific embodiment adopts the following technical solutions: a film unloading device for PVC decorative film production, including a frame 1, and a number of firm ribs 2 are evenly fixed and connected between the two side walls of the inner bottom of the frame 1, The upper end of the stable reinforcing rib 2 is horizontally provided with an output belt 3 in the frame 1, and several film material supports 4 are fixedly connected to both sides of the upper end of the frame 1 respectively, and the upper ends of the two film material supports 4 are fixedly connected with Bearing mounts 5, film rolls 6 are rotatably connected between the two bearing mounts 5, a welding tripod 10 is fixedly connected to the outer wall of one side of the frame 1, and the welding tripod 10 is close to the frame 1 One side is fixedly connected with the frame 1 through high-strength hexagon socket head stop bolts 11, the upper end of the welding tripod 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com