A method for safely hoisting pipe piles

A hoisting method and pipe pile technology, applied in the field of spreaders, can solve problems such as potential safety hazards, hoisting tripping, lack of protective measures, etc., and achieve the effects of stable transportation, fast installation, and improved protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

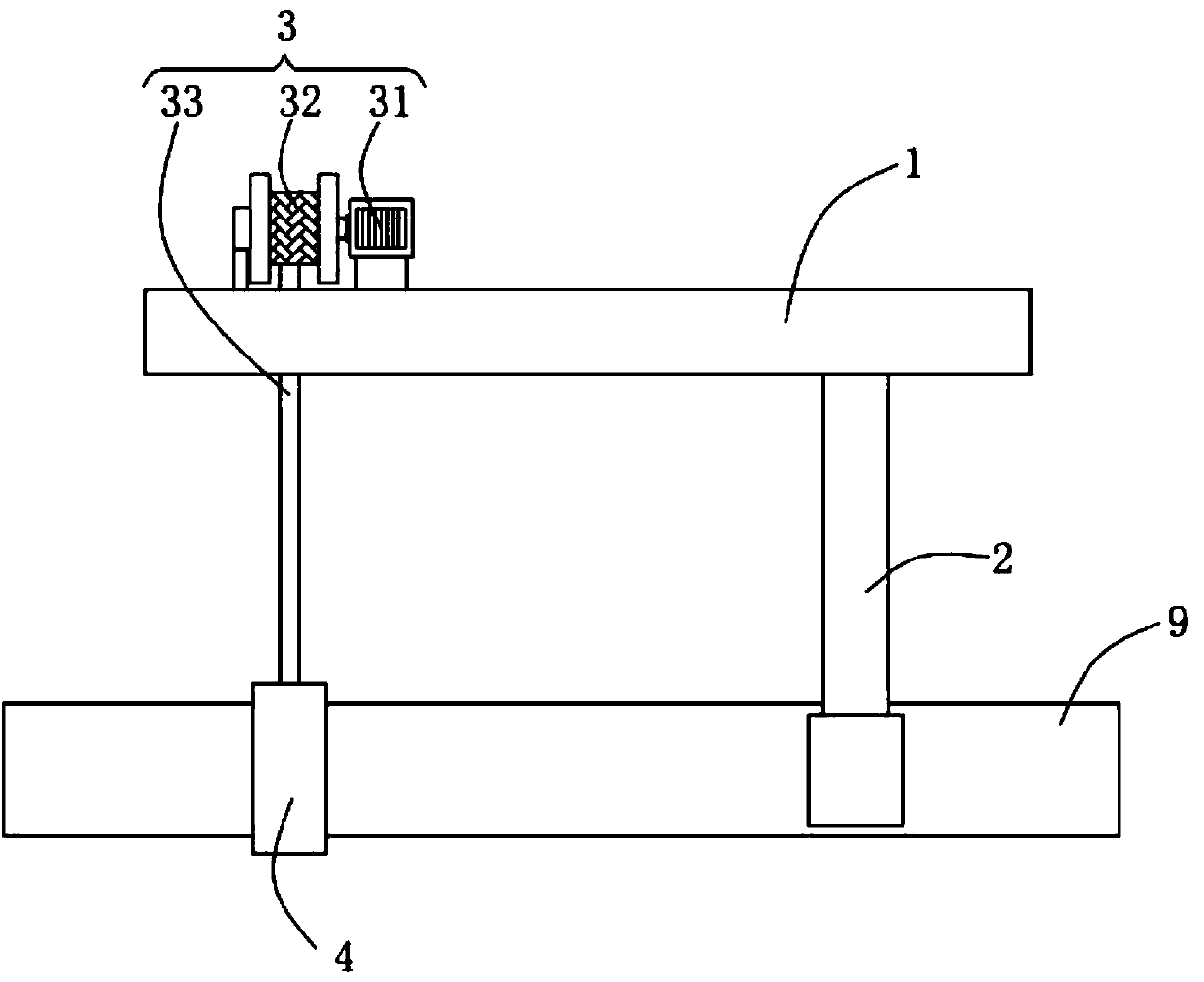

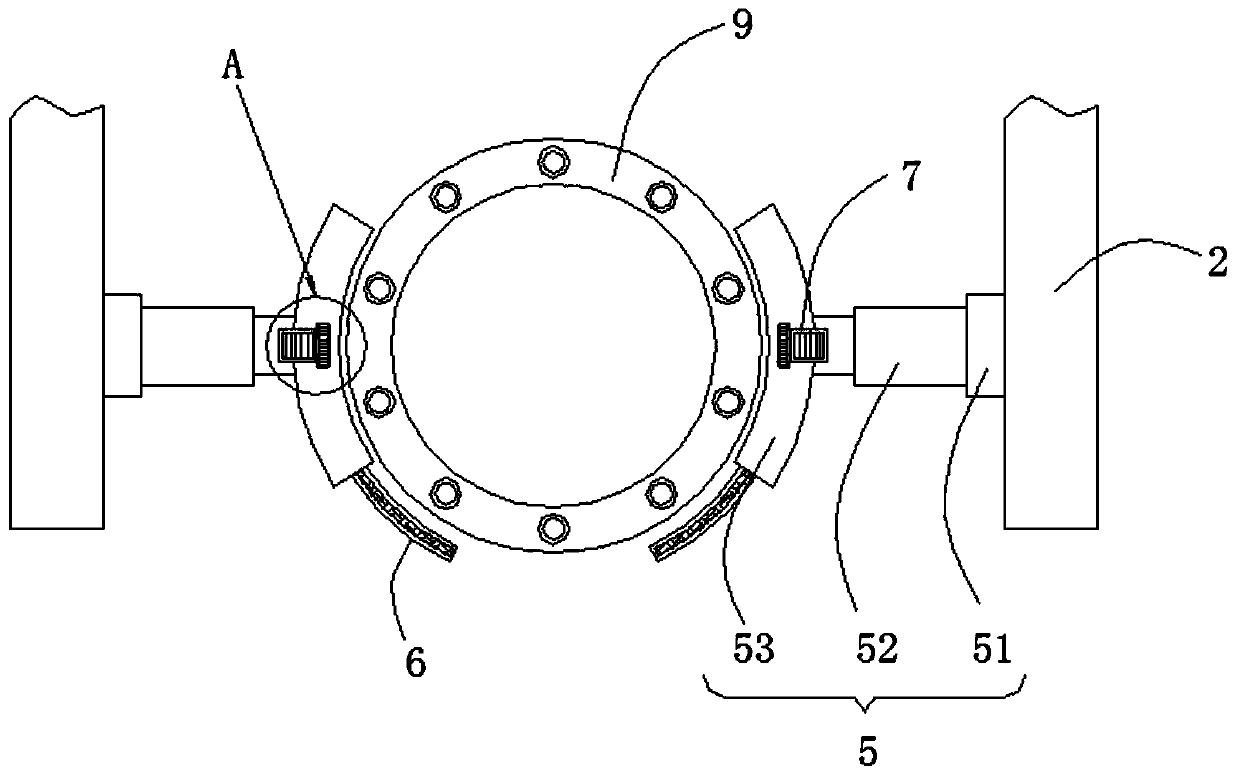

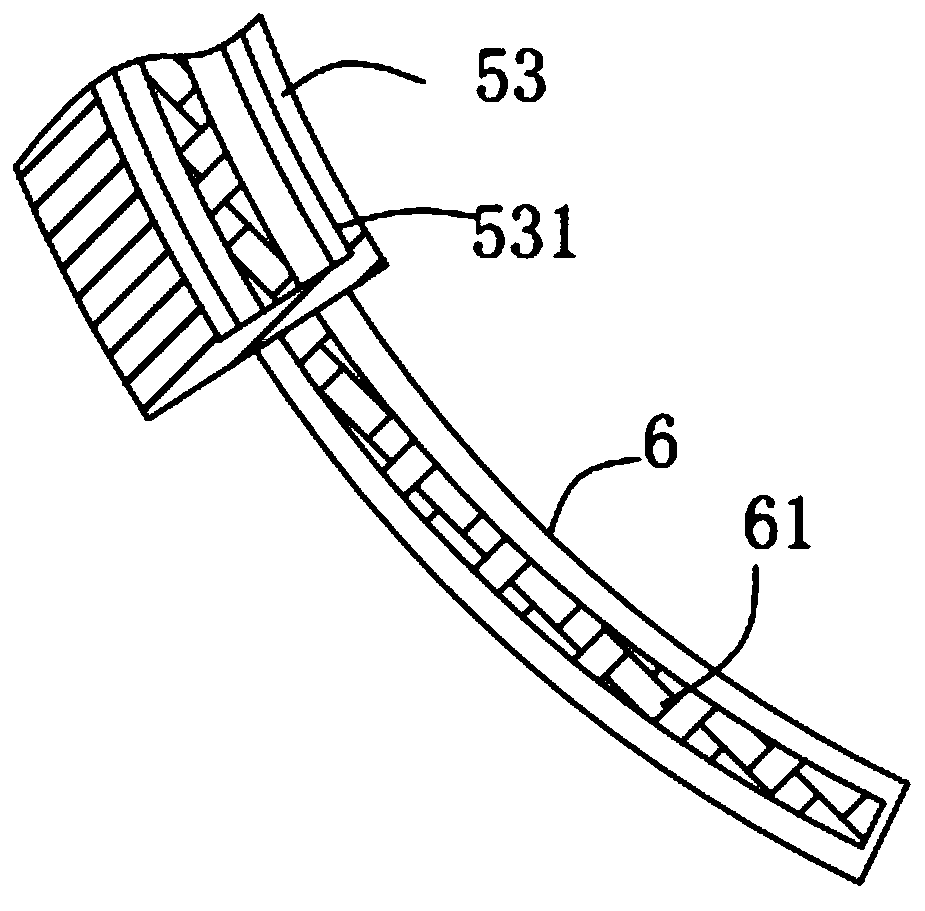

[0031] Such as Figure 1-Figure 5 As shown, a method for safely hoisting pipe piles according to the present invention comprises the following steps:

[0032] S1, installing a special spreader for pipe piles on the row frame;

[0033] S2, use the special spreader for pipe piles in S1 to fix the pipe piles, and then slowly lift the pipe piles about 20 cm from the ground;

[0034] S3, then the wire rope is bypassed from the bottom of the pipe pile, the two ends of the wire rope are respectively fixed on the special spreaders for pipe piles on both sides of the pipe pile, and the lowest end of the wire rope is in contact with the ground;

[0035] S4, the metal adjustment block is hung on the bottom of the steel wire rope in S3, and the metal adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com