Laser cutting device for special-shaped hardware

A cutting device and hardware technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of affecting cost, locking and positioning of difficult-shaped hardware, and low cutting accuracy, so as to increase work efficiency and ensure Positioning effect, improve the effect of cutting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

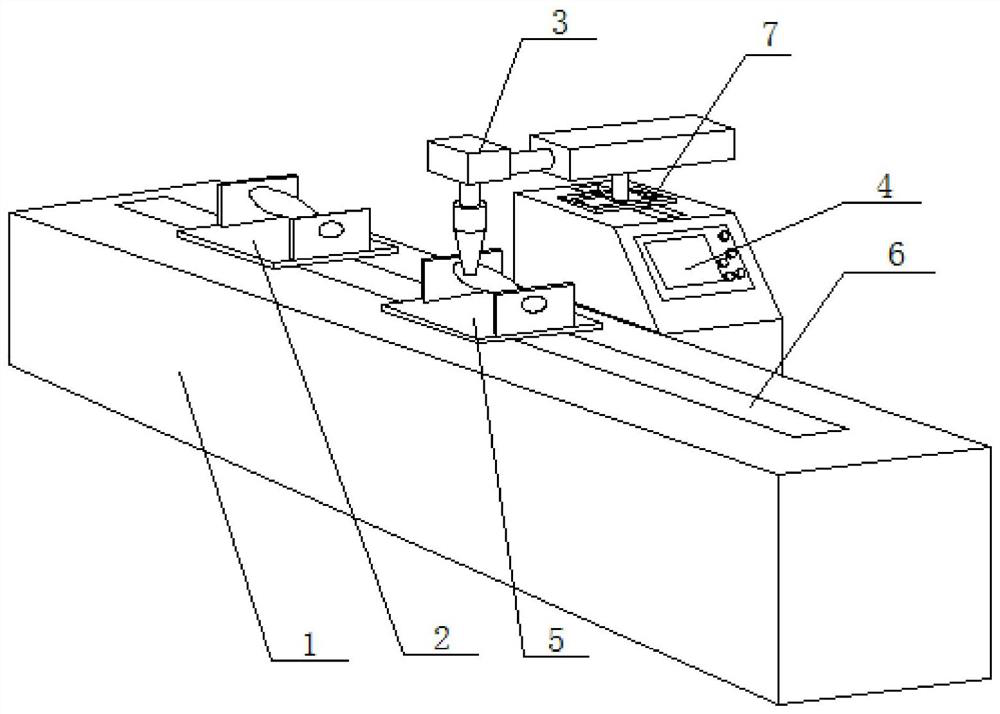

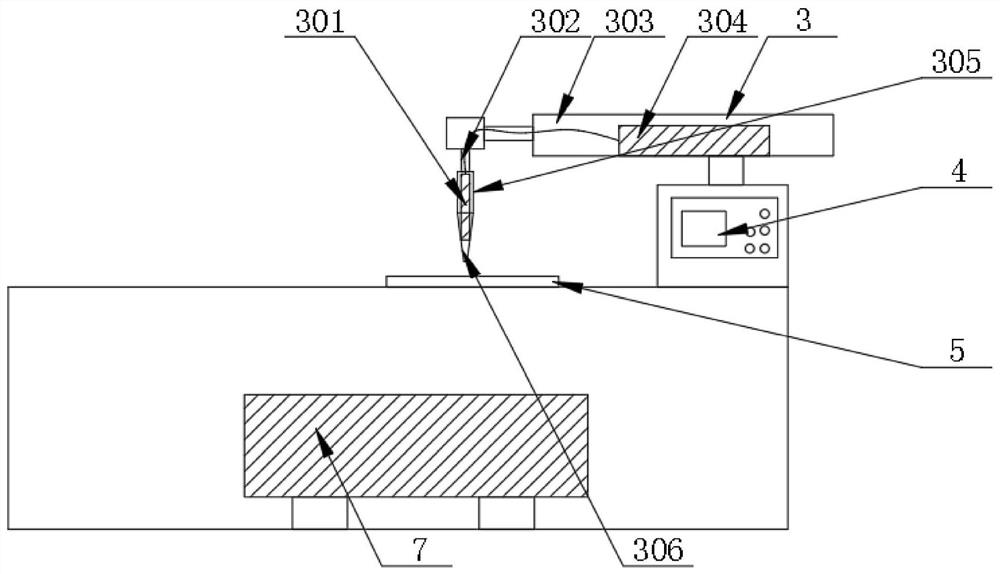

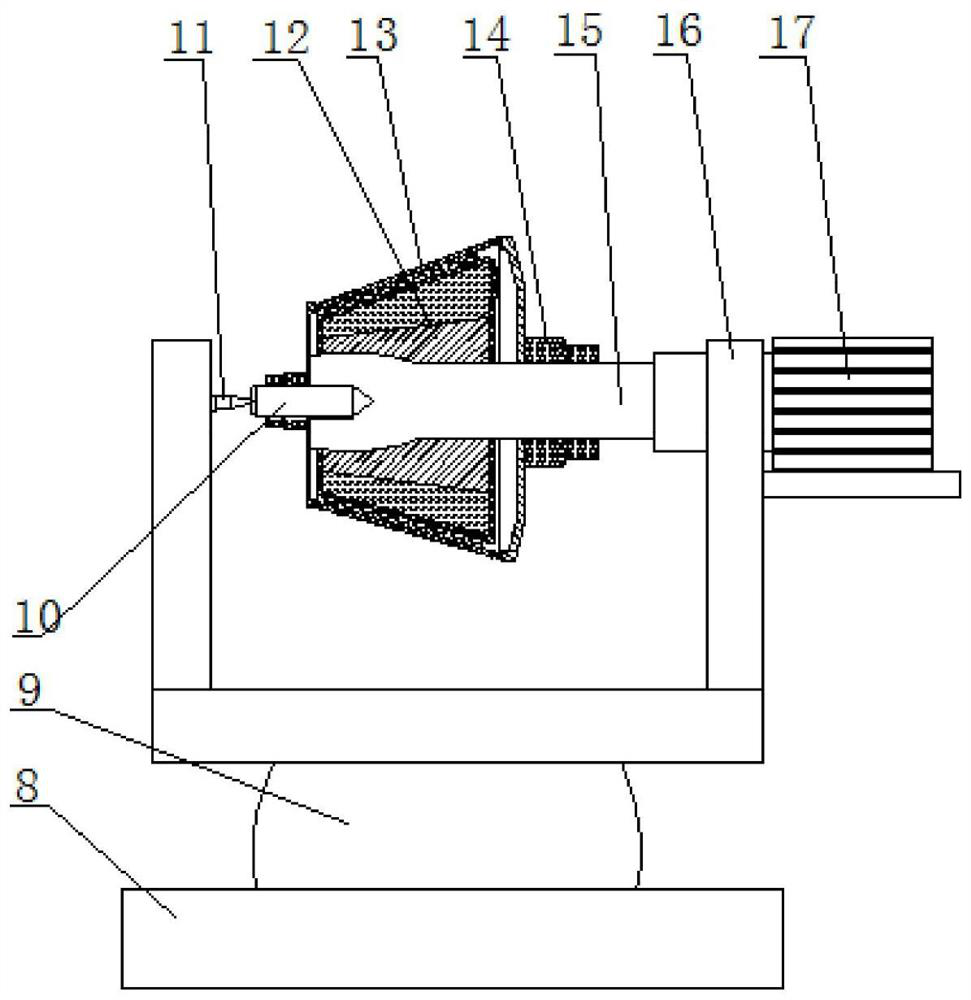

[0025] see Figure 1-6 , in the embodiment of the present invention, the special-shaped hardware laser cutting device includes a machine base 1, a feeding station 2, a cutting station 5, a laser cutting machine 3 and a special-shaped hardware positioning and locking mechanism 12, wherein the machine base 1 extends along its length direction and is provided with the feeding station 2 and the cutting station 5 in sequence, the laser cutting machine 3 is arranged above the cutting station, and the positioning and locking mechanism of the special-shaped hardware can be Move between the feeding station and the cutting station along the extension direction of the machine base; it is characterized in that the special-shaped hardware 13 is a thin-walled non-circular special-shaped ring, and the special-shaped hardware is positioned and locked The inner wall of the special-shaped hardware can be tightened, positioned and locked from the inner cavity of the special-shaped hardware to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com