Flotation technology for removing sesquioxides and magnesium impurities in silicon-calcium collophanite

A technology based on sesquioxide and silicon-calcium, which is applied in flotation, solid separation, etc., can solve the problems of large dosage, restricting development, heating flotation, etc. The effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

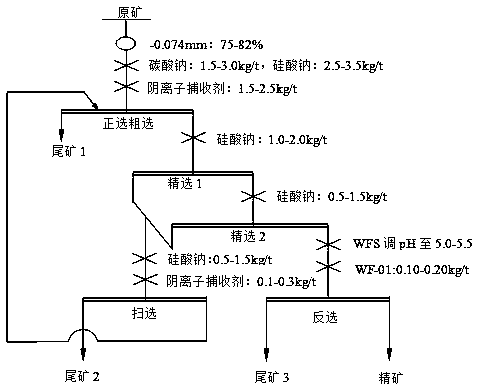

[0028] For a silicon-calcium colloidal phosphate rock in Guizhou, raw ore P 2 o 5 23.40%, MgO 2.82%, SiO 2 17.76%, R 2 o 3 5.61%, according to the following process methods:

[0029] 1) Crush and grind the raw ore to -0.074mm to account for 80%, add water to adjust the slurry to a mass concentration of 25%; the slurry temperature is 20°C; the sodium silicate modulus is 2.5;

[0030] 2) First roughing of positive flotation: add 2.0kg / t raw ore sodium carbonate and 3.0kg / t raw ore sodium silicate, pH is controlled at 9.5, then add 1.5kg / t raw ore unsaturated oleic acid soap anion collector, The material left in the flotation tank after aerated flotation is used as positive flotation roughing tailings, phosphate and carbonate minerals and some iron-aluminosilicate minerals enter the roughing foam product;

[0031]3) Two times of selection and one sweeping of positive flotation: add 1.0kg / t raw ore sodium silicate to the roughing foam product, perform a positive positive flo...

Embodiment 2

[0037] For a silicon-calcium colloidal phosphate rock in Guizhou, raw ore P 2 o 5 21.90%, MgO 2.77%, SiO 2 18.02%, R 2 o 3 6.42%, according to the following process methods:

[0038] 1) Crush and grind the raw ore to -0.074mm to account for 78%, add water to adjust the slurry to a mass concentration of 27%; the slurry temperature is 23°C; the sodium silicate modulus is 2.0;

[0039] 2) First roughing of positive flotation: add 2.2kg / t raw ore sodium carbonate and 2.8kg / t raw ore sodium silicate, control pH at 10.0, then add 2.0kg / t raw ore unsaturated oleic acid soap anion collector, The material left in the flotation tank after aerated flotation is used as positive flotation roughing tailings, phosphate and carbonate minerals and some iron-aluminosilicate minerals enter the roughing foam product;

[0040] 3) Two times of selection and one sweep of positive flotation: add 1.2kg / t raw ore sodium silicate to the roughing foam product, perform a positive positive flotation ...

Embodiment 3

[0046] For a silica-calcium collophosite in Hubei, raw ore P 2 o 5 23.35%, MgO 2.72%, SiO 2 18.65%, R 2 o 3 5.78%, according to the following process methods:

[0047] 1) Crush and grind the raw ore to -0.074mm to account for 82%, add water to adjust the slurry to a mass concentration of 25%; the slurry temperature is 25°C; the sodium silicate modulus is 3.0;

[0048] 2) First roughing of positive flotation: add 3.0kg / t raw ore sodium carbonate and 3.5kg / t raw ore sodium silicate, control the pH at 11, then add 2.5kg / t raw ore unsaturated oleic acid soap anion collector, The material left in the flotation tank after aerated flotation is used as positive flotation roughing tailings, phosphate and carbonate minerals and some iron-aluminosilicate minerals enter the roughing foam product;

[0049] 3) Two times of selection and one sweep of positive flotation: add 2.0kg / t raw ore sodium silicate to the roughing foam product, perform a positive positive flotation selection wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com