Steel scrap crusher dust removal and impurity removal device based on waterpower and wind power

A crusher and wind power technology, which is applied in the field of dust removal and impurity removal devices of scrap steel crushers, can solve the problem of inability to remove a small amount of plastic and other debris from scrap steel, and achieve the effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

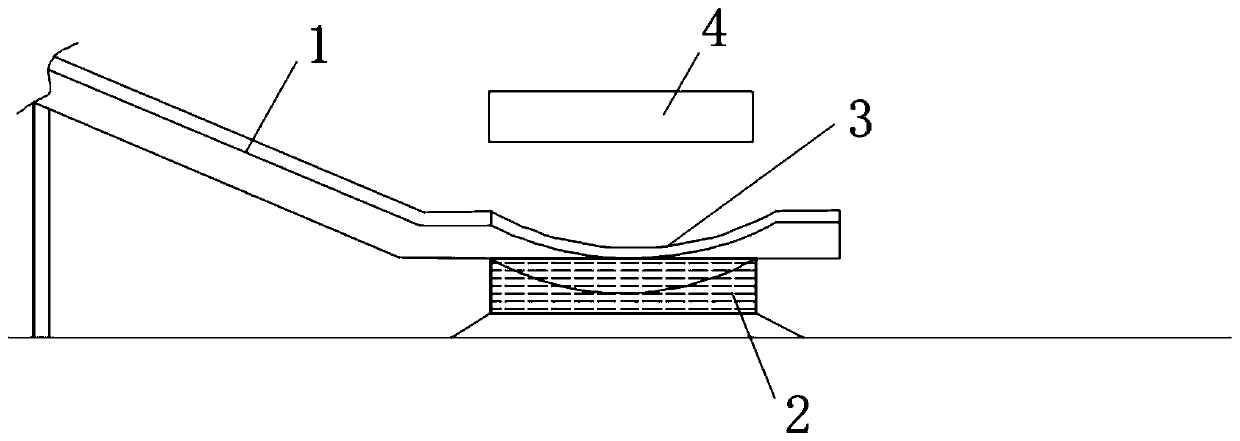

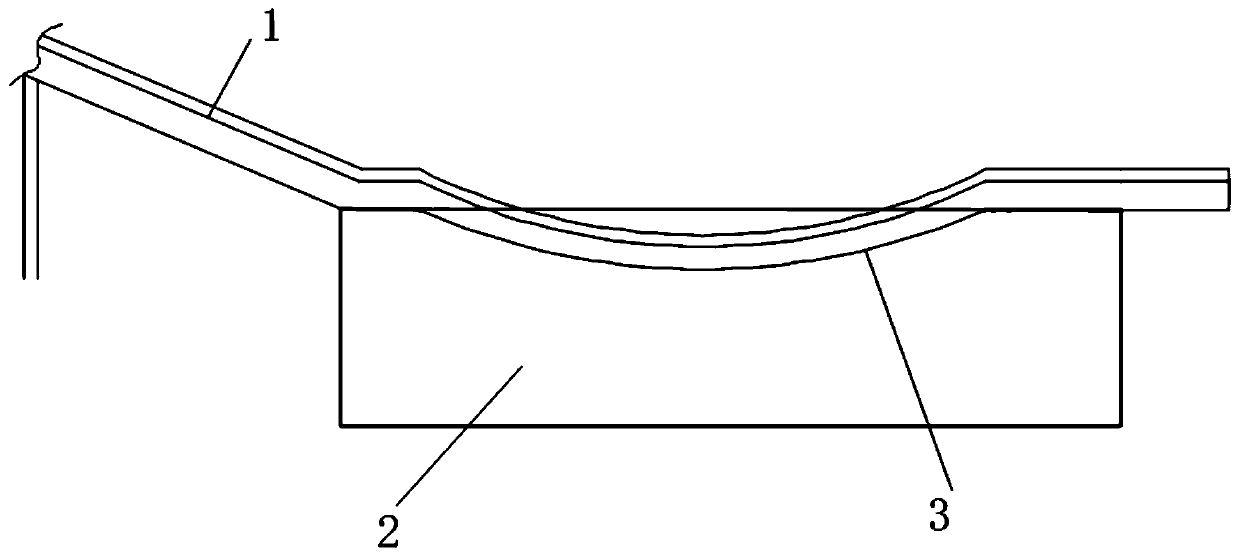

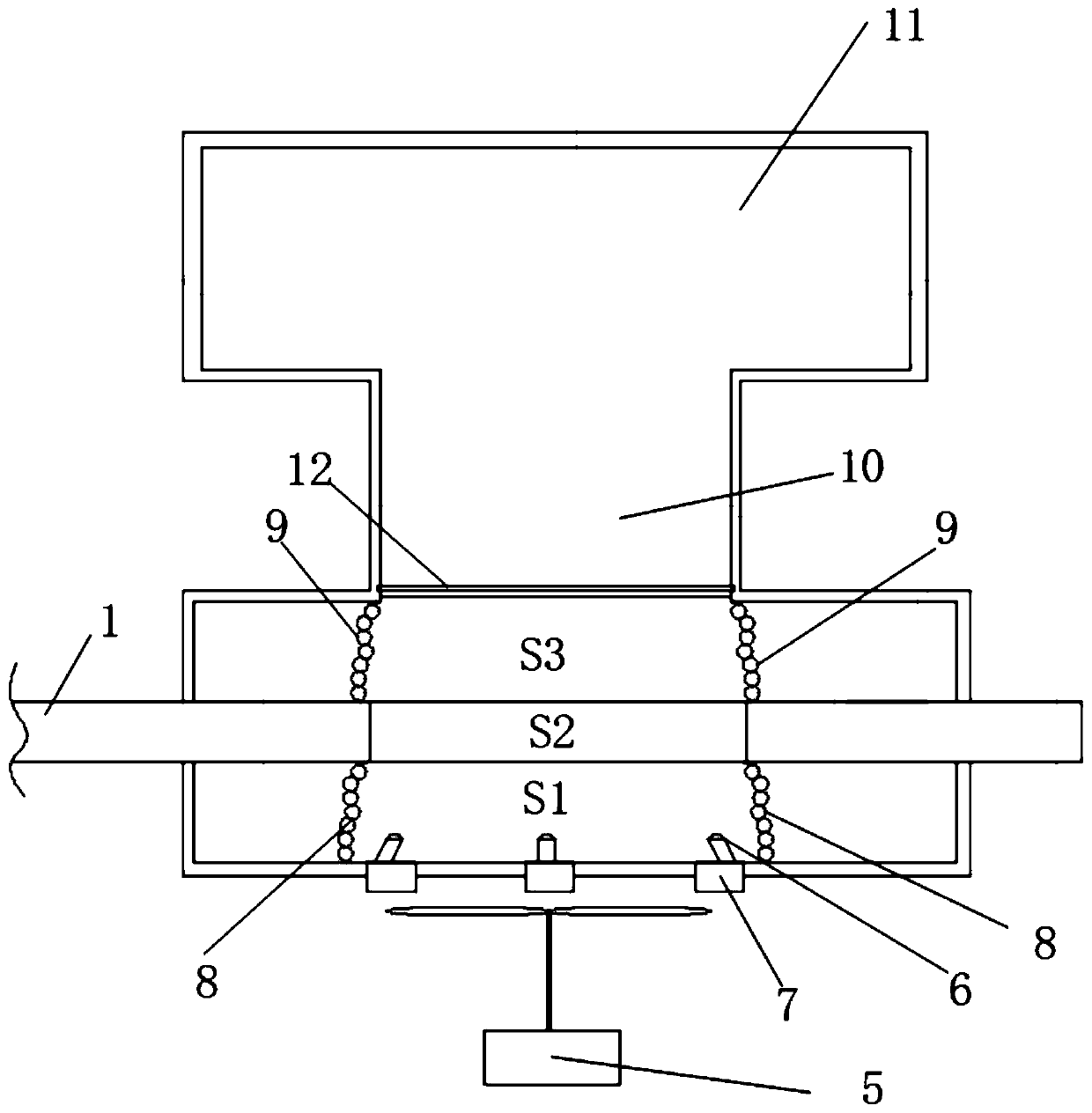

[0029] Such as Figure 2-3 , a scrap steel crusher dust removal and impurity removal device based on hydraulic and wind power, which includes: a heavy-duty feeding conveying crawler belt 1 installed at the feeding port of the scrap steel crusher, and the input end of the heavy-duty feeding conveying crawler belt 1 has a downward concave The arc-shaped transmission structure section 3, the arc-shaped transmission structure section 3 is immersed in the pool 2 matched therewith, the arc-shaped transmission structure section 3 sinks under the water surface of the pool 2, and the arc-shaped transmission structure section 3 A water surface for floating objects is formed above, the front of the pool is provided with an air supply device 5 towards the water surface for floating objects, such as a fan, and the front wall of the pool is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com