Double-shaft shredding machine for shredding cylinders

A dual-shaft shredder and cylinder technology, used in grain processing and other directions, can solve problems such as easy slippage, achieve the effects of not easy to slip, prolong service life, and facilitate shredding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

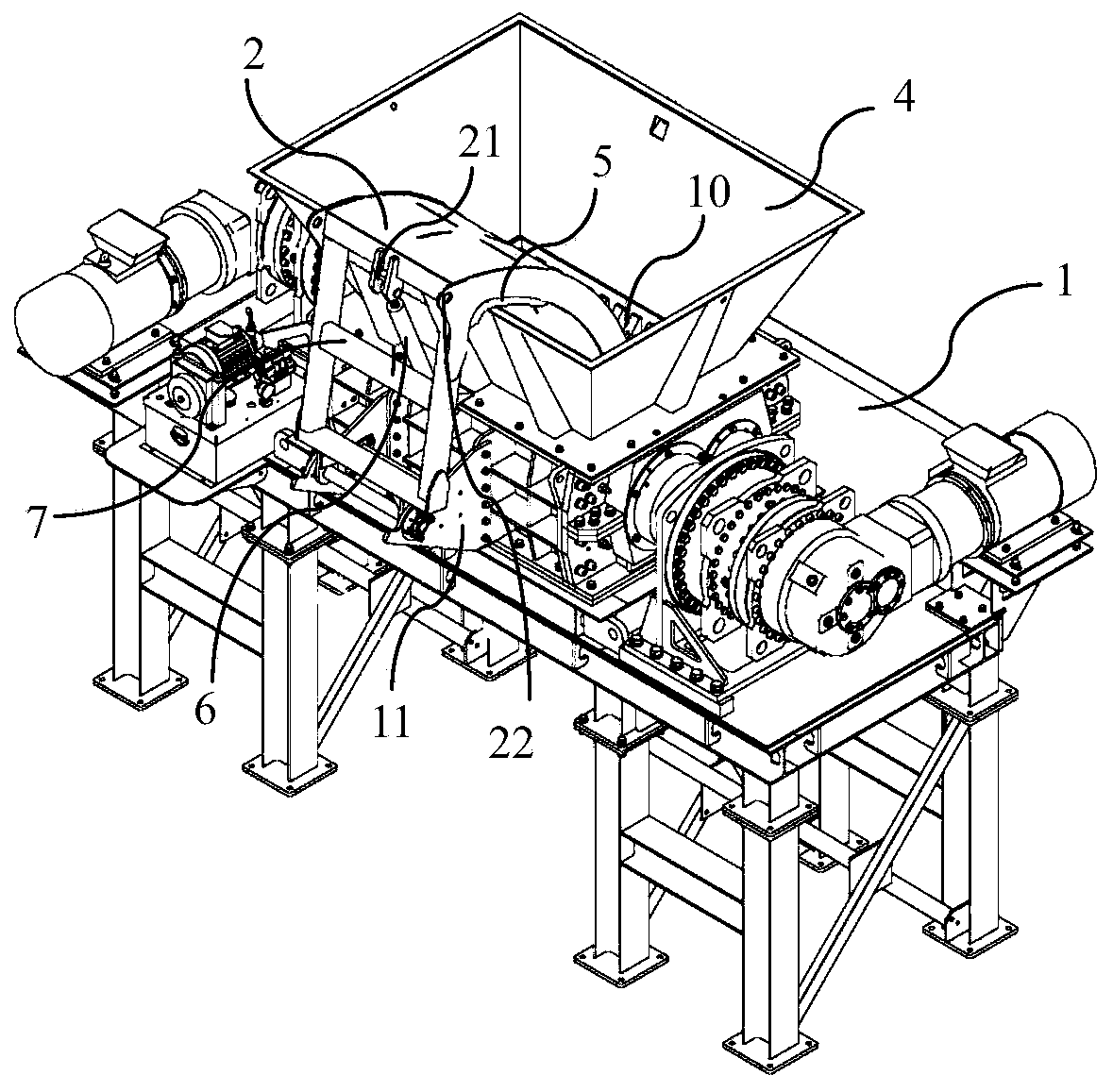

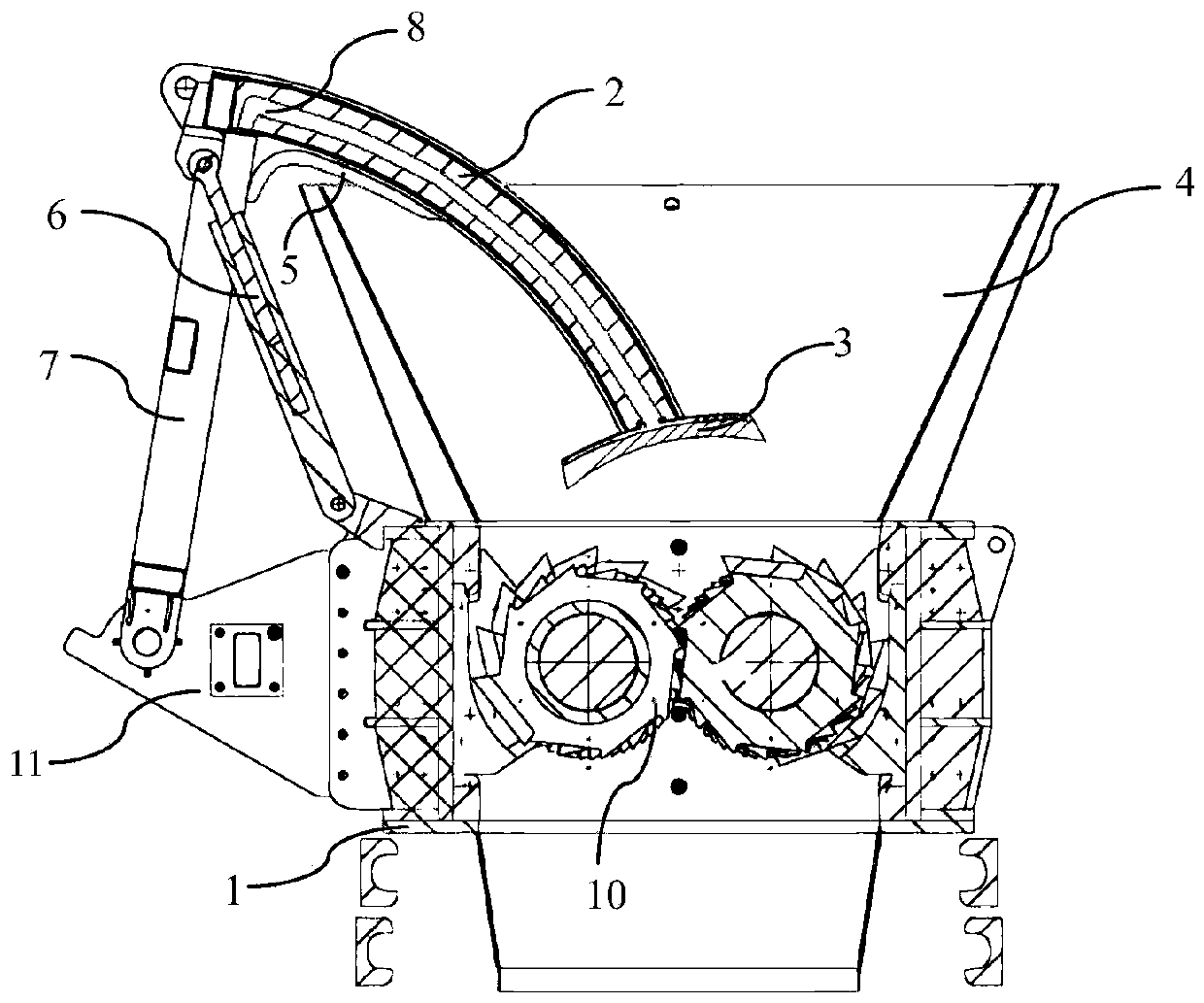

[0032] Such as figure 1 , figure 2 As shown, a shredding cylinder twin-shaft shredder includes a stand 1 , a pressure plate 2 , a contact 3 , a hydraulic cylinder 6 , a support rod 7 , a knife roller 10 , a support plate 11 and a conduit 8 .

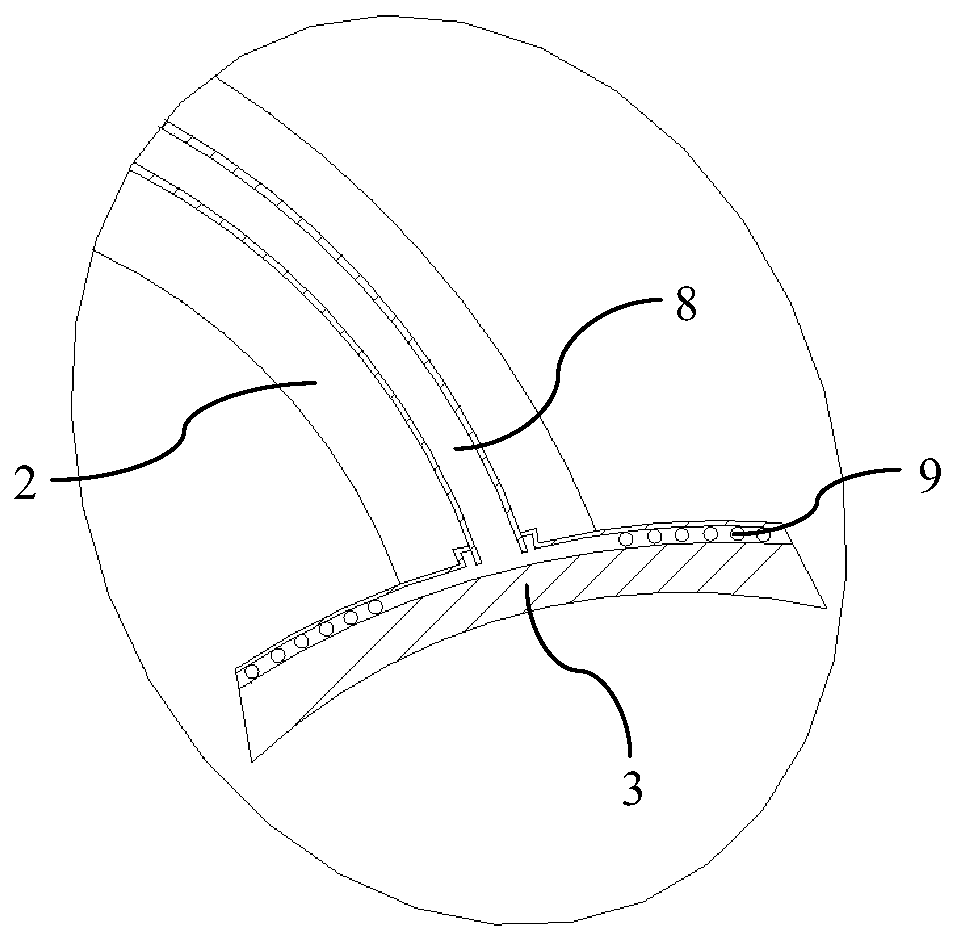

[0033] In this embodiment, the pressure plate 2 is provided with a connection block 21 and a lug 22, the connection block 21 of the pressure plate 2 is hinged with the piston rod of the hydraulic cylinder 6, and the end of the pressure plate 2 facing the knife roller 10 is connected by a threaded connection. Head 3; one end of the cylinder body of the hydraulic cylinder 6 is hinged to the stand 1; one end of the support rod 7 is fixed to the pressure plate 2 through the lug 22, and the other end of the support rod 7 is hinged to the support plate 11; the support plate 11 is fixed to the stand 1. The conduit 8 extends from the top of the pressure plate 2 to the bottom, and is connected to the contact 3 by threads, which can be sealed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com