A Controllable Depth Surface Defect Machining Method Based on Ultrasonic AFM Closed-loop System

A closed-loop system and processing method technology, applied in control/regulation systems, controllers with specific characteristics, electric controllers, etc., can solve problems such as excessive processing, needle tip wear, repeated processing, etc., to achieve precise control, improve reliability. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

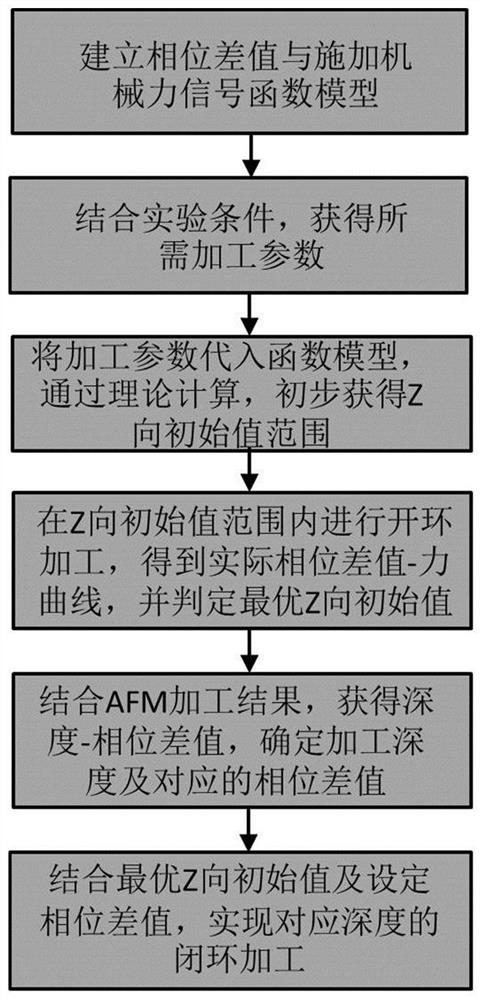

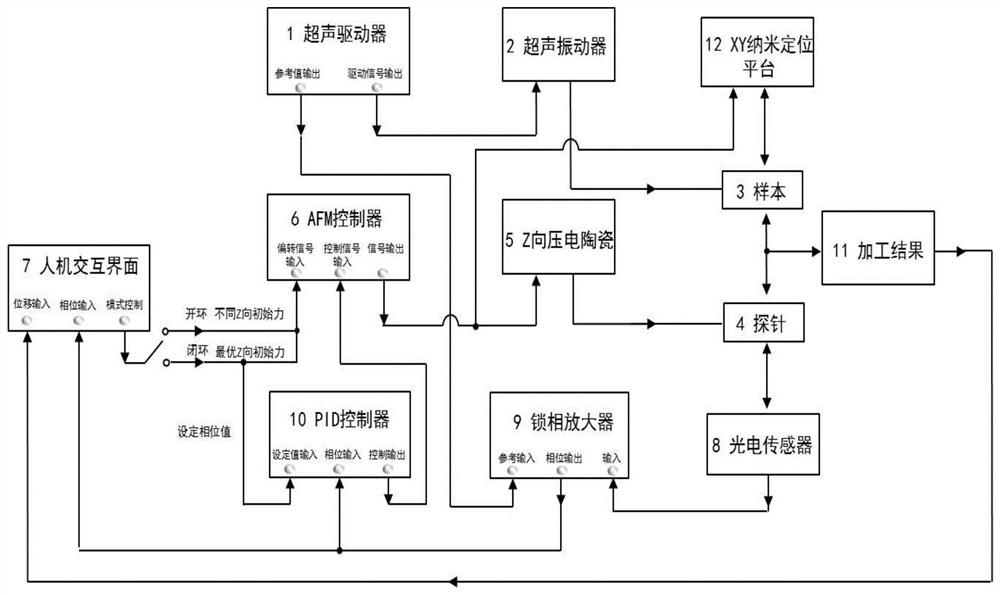

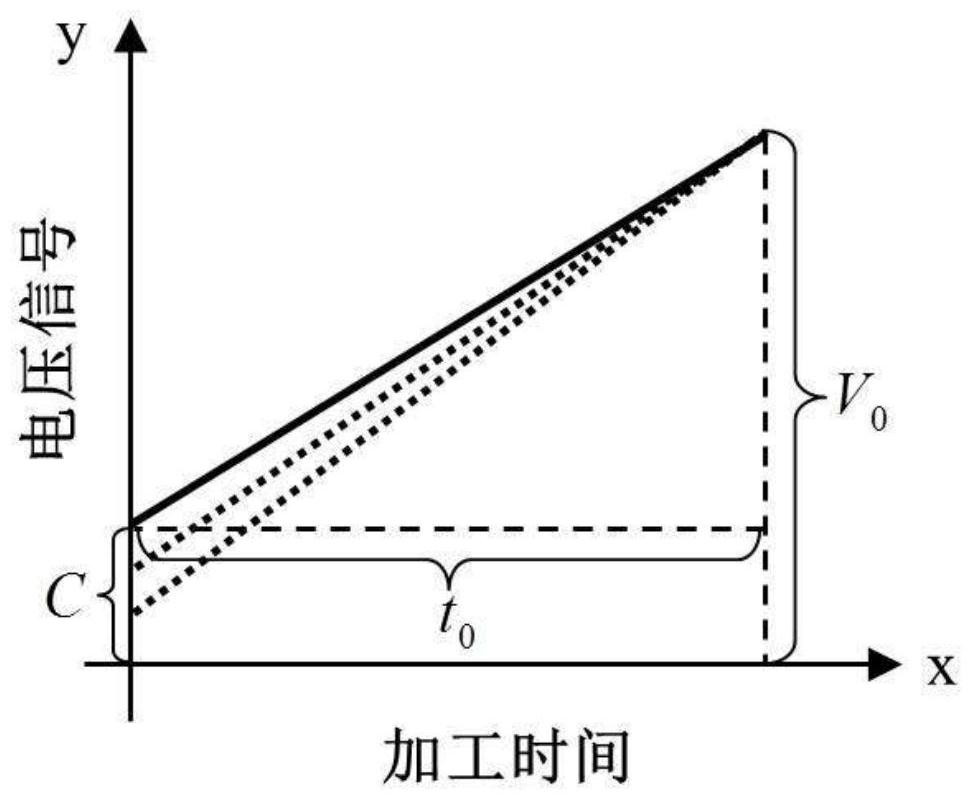

[0053] The present invention finally realizes precise processing of surface defects of nanometer materials at different depths by obtaining the information of processing depth and phase value. The invention relates to a method for processing surface defects of nanometer materials with controllable depth based on an ultrasonic AFM closed-loop system. The method includes establishing a function model of ultrasonic processing phase and applied mechanical force signal, substituting relevant processing parameters to obtain the range of Z-direction initial value of mechanical force signal; obtaining the actual phase difference-mechanical force curve and the optimal Z-direction initial value in open-loop mode; Combining the AFM processing results to obtain the phase value of different processing depths of nanomaterials; combining the optimal Z-direction initial valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com