Heat collecting heat exchange system and heat collecting heat exchange method for worked-out section

A heat exchange system and goaf technology, which is applied in the field of coal mining, can solve the problems that the heat source cannot be brought out of the ground and the gob heat source has not been developed and utilized, and achieves the effects of reducing energy consumption, improving heat utilization rate and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings. The terms "inner" and "outer" are used to refer to directions toward and away from, respectively, the geometric center of a particular component.

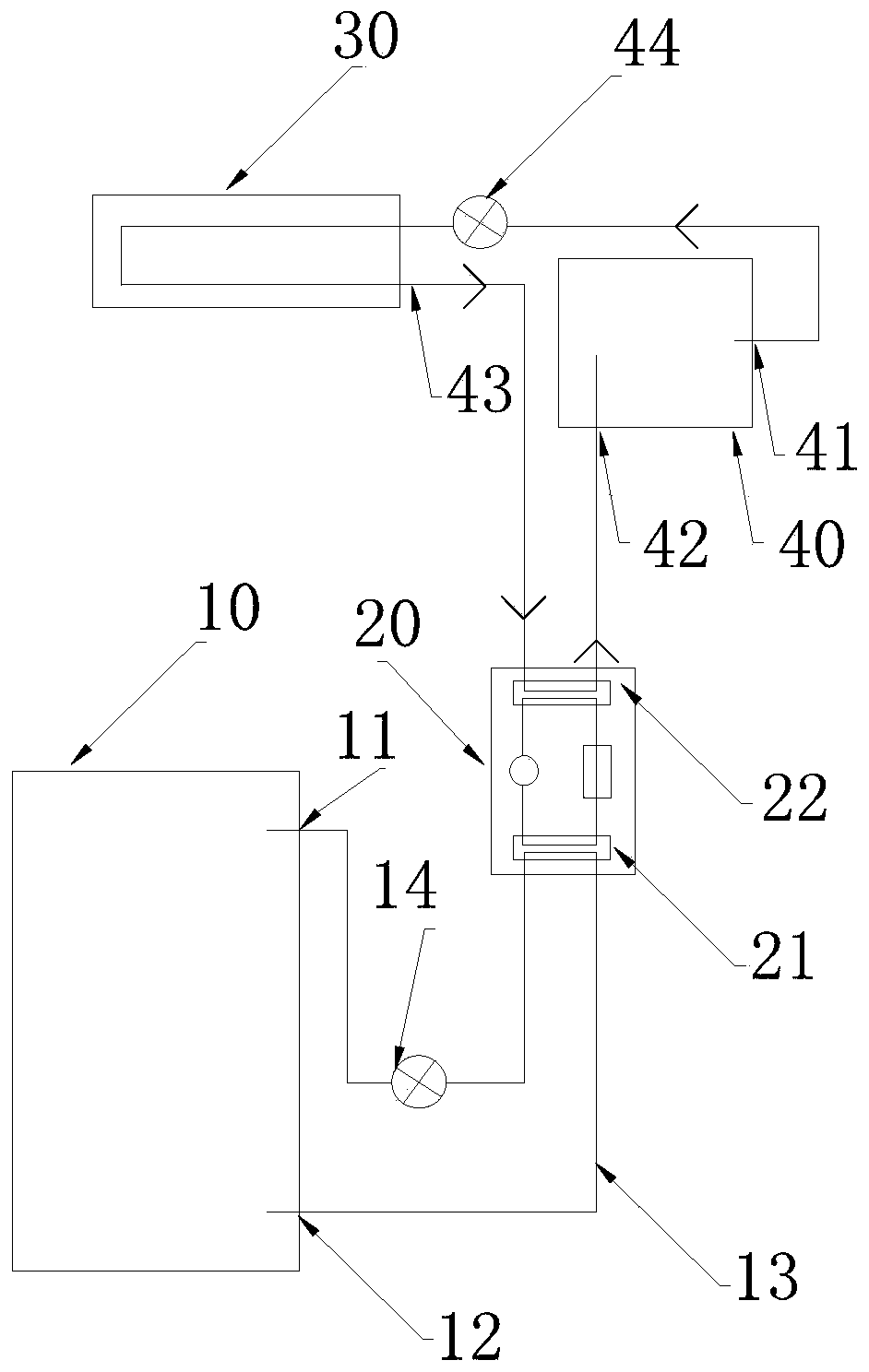

[0032] figure 1 It is a schematic diagram of the goaf heat collection and heat exchange system adopted in the specific embodiment of the present invention. Such as figure 1 As shown, the goaf heat collection and heat exchange system includes: a goaf catchment area 10, a water storage tank 40 and a heat pump device 20.

[0033] The goaf catchment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com