Full-diameter switchable slide sleeve for fracturing and using method thereof

A full-bore, sliding-sleeve technology, used in natural gas extraction and oil fields, can solve the problems of complex rotating mechanism, increased additional workload, and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

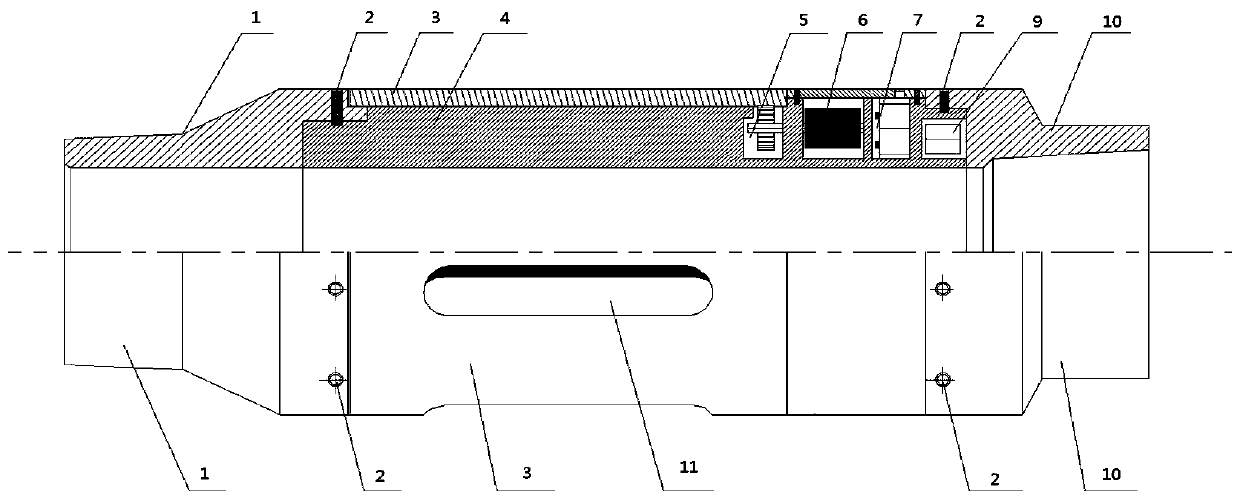

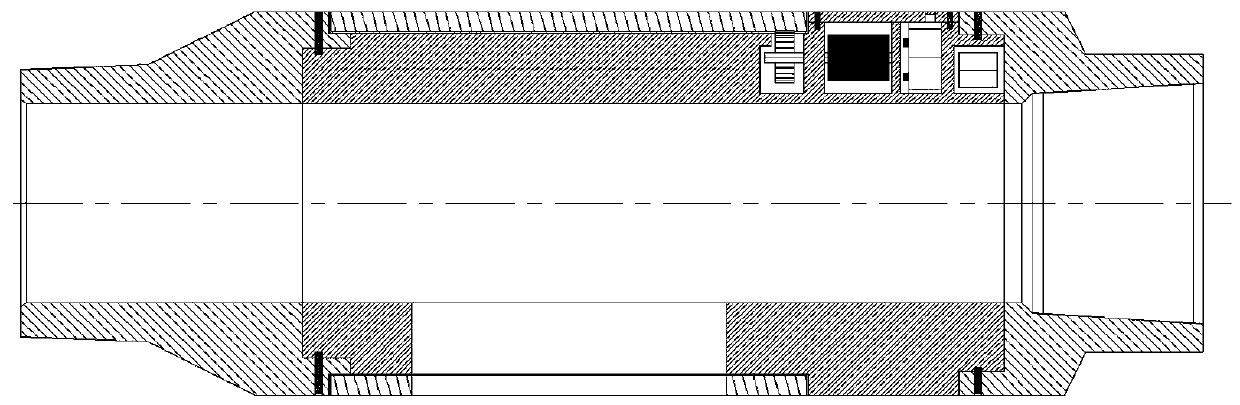

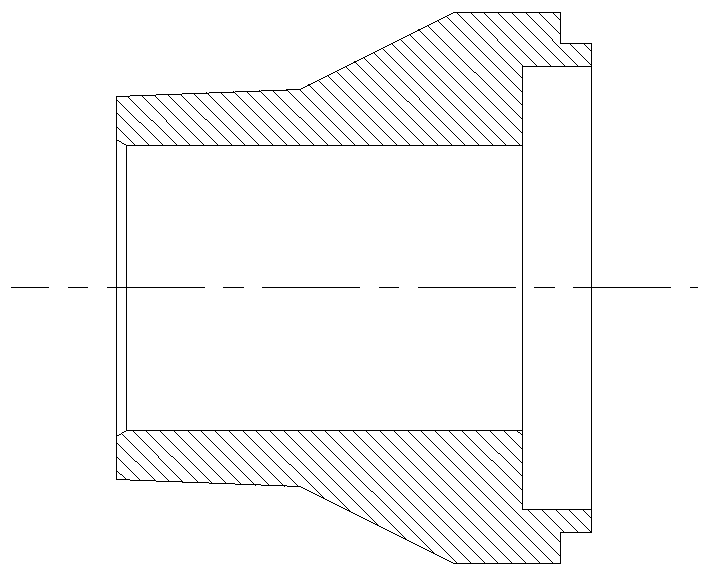

[0030] A full-diameter switchable sliding sleeve for fracturing, including an upper joint 1, a lower joint 10, a sliding sleeve body 4 and an outer sliding sleeve 3; the upper end of the sliding sleeve body 4 is connected to the upper joint 1 through a connecting pin 2, The lower end is connected to the lower joint 10 through the connecting pin 2; the outer sliding sleeve 3 is located on the outside of the sliding sleeve body 4, and is rotatably connected with the sliding sleeve body 4; the sliding sleeve body 4 and the outer sliding sleeve 3 are equipped with five Annular grooves 11 of the same size; the outer sliding sleeve 3 is provided with a driven gear, and the sliding sleeve body 4 is provided with a driving gear for driving the driven gear. The driving gear drives the passive gear and then drives the outer sliding sleeve 3 to rotate forward, so that the annular groove 11 on the sliding sleeve body 4 coincides with the annular groove 11 on the outer sliding sleeve 3, tha...

Embodiment 2

[0032] On the basis of Embodiment 1, the inner wall of the outer sliding sleeve 3 is provided with a driven gear, that is, an inner gear 24, and correspondingly, the outer wall of the sliding sleeve body 4 is also provided with an external gear 13 matching the inner gear 24, That is, the driving gear; also includes a driving device for driving the external gear 13 .

Embodiment 3

[0034]On the basis of embodiment 2, it also includes a communication chamber 9, a control chamber 7, a transmission chamber 6 and an execution chamber 5 that are located in the sliding sleeve body 4 and interact with each other; it also includes a ground control system; the communication chamber The chamber 9 includes an acoustic-electric conversion module 20 and an A / D conversion module 21 connected in sequence, the acoustic-electric conversion module 20 is electrically connected to the ground control system, and the A / D conversion module 21 is electrically connected to the MCU 22 . The control chamber 7 includes an MCU 22 and a power supply module 17 connected to the MCU 22; the power supply module 17 is a lithium battery, and the power supply module 17 is also provided with a charging interface 18 for charging. Described transmission chamber 6 comprises transmission bearing 12 and is connected with transmission bearing 12 and is the motor module 15 that provides electric ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com