Device and method for detecting quantitative relation of interaction action of molten iron sulfide in furnace cylinder

A technology of interaction and quantitative relationship, applied in the field of blast furnace ironmaking, can solve the problem of not obtaining the quantitative relationship of the interaction of molten iron, sulfur and titanium, and achieve the effect of scientific and reasonable method and prolonging the life of the hearth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Select hearth molten iron samples with known composition in different periods of a specific blast furnace. Select the molten iron sample between [S]=0.02~0.08%, and select the molten iron sample between [Ti]=0.05~0.15% when [S] is relatively fixed. Each sample 200g, the composition of the selected molten iron sample is as shown in Table 1:

[0069] Table 1 Composition of hearth molten iron samples

[0070]

[0071]

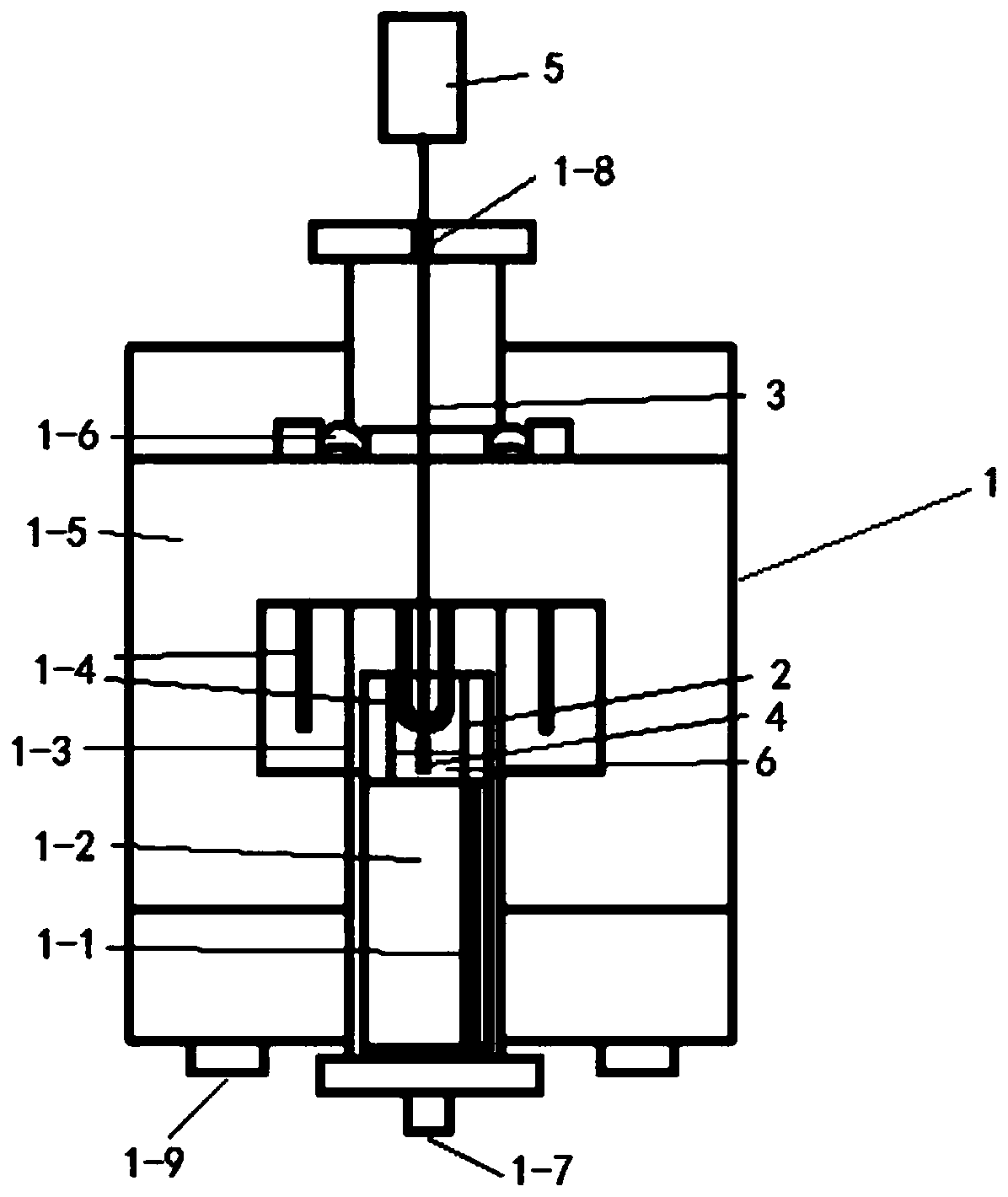

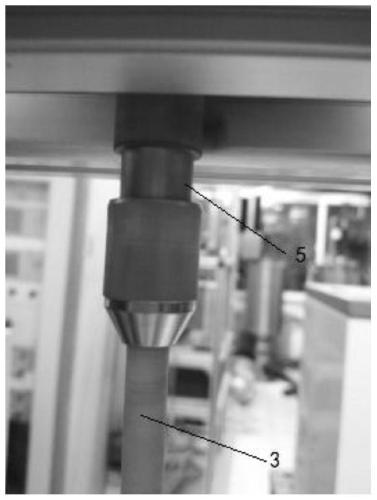

[0072] (2) Cut the hearth carbon brick into a cylindrical rod sample of Φ12×50mm with a special drill. Before the experiment started, the carbon brick cylindrical rod sample and the corundum rod were bonded together to form a stirring rod (such as figure 2 shown). The specific process is: 1) Use 302 glue to stick the carbon brick cylindrical rod sample and the corundum rod, and dry it; 2) Mix the high-temperature binder and fiber powder to a paste; 3) Put a layer of paste binder The first layer is coated on the junction of the carbon brick cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com