Diesel engine cylinder sleeve lifting appliance and lifting method

A diesel engine and cylinder liner technology, which is applied to the special spreader and hoisting of diesel engine cylinder liners, and special fixtures for diesel engine parts, which can solve the problems of increasing the manufacturing cost of the whole machine, delaying delivery, and easy deformation of cylinder liners. Achieve the effects of good versatility, improve lifting efficiency, and avoid bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

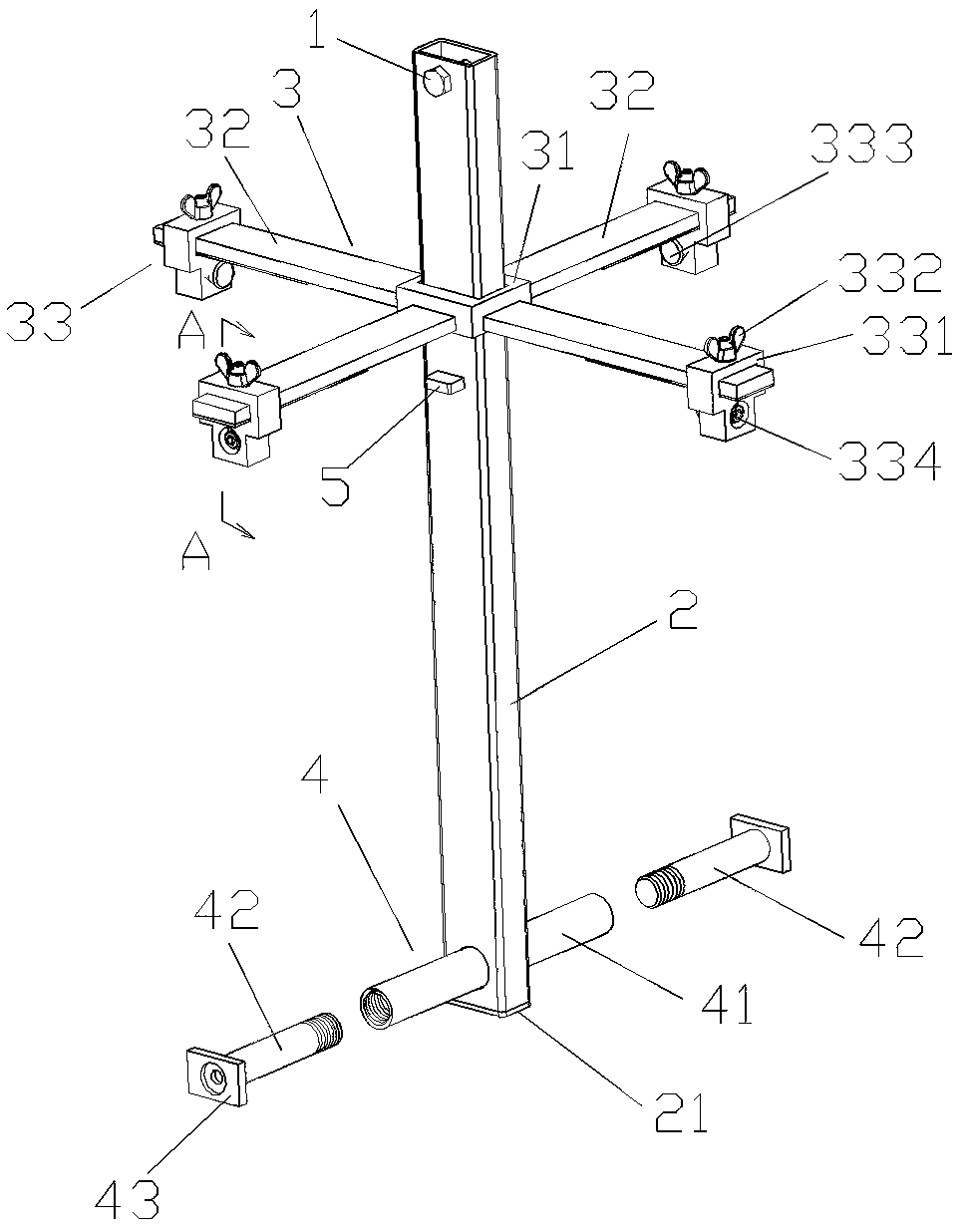

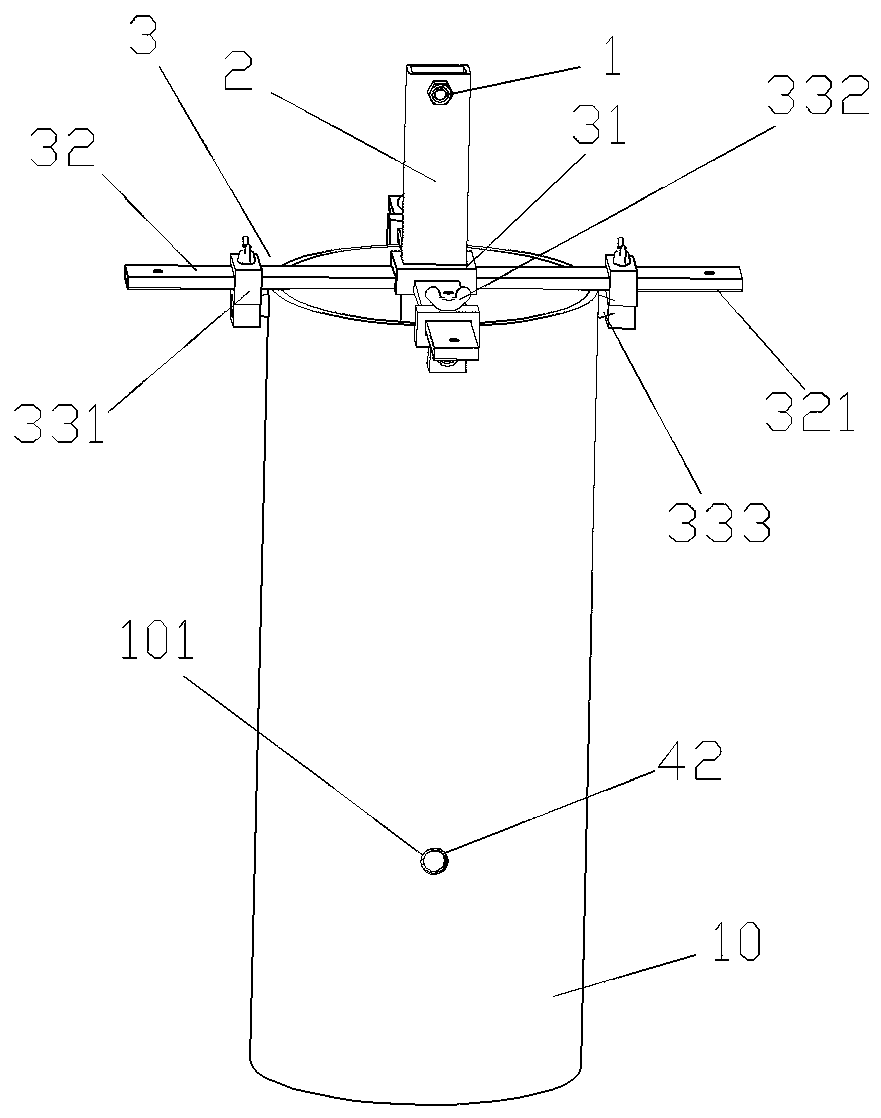

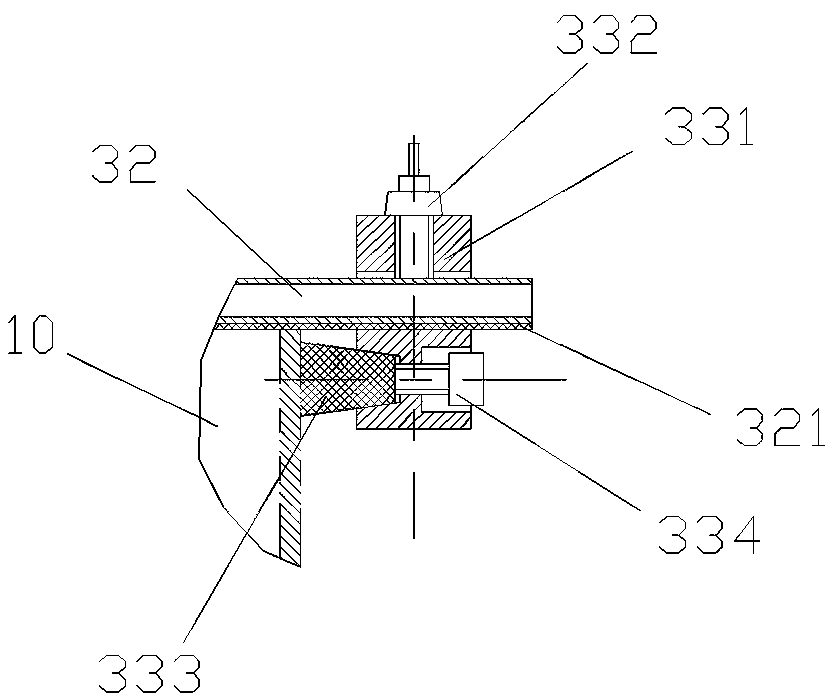

[0025] like Figure 1 ~ Figure 3 As shown, the present invention includes a lifting screw nut group 1, a central suspender 2, a gimbal assembly 3 and a fixed cross bar assembly 4, and the central suspender 2 is arranged vertically and is made of a rectangular steel pipe. The center suspender 2 bottom is closed by a stuffy cover 21. It can collect the rust or other impurities falling from the rusty wire rope or hook during the hoisting process, and prevent it from falling along the cylinder liner 10 to the scavenging air box and the oil pan, polluting the lubricating oil system inside the diesel engine. Lifting screw nut group 1 is placed horizontally and is fixed on the upper end of center suspender 2, also can adopt the structure that hoisting shackle is installed in center suspender 2 upper end and lifts.

[0026] The horizontal balance frame assembly 3 is used to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com