Quantitative feeding device of food material

A technology for food materials and equipment, applied in the field of quantitative cutting equipment for food materials, can solve the problems of difficult to collect and quantitative cutting waste water, and achieve the effect of ensuring sanitary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the food processing industry, it is necessary to unload the ingredients to be cooked. The existing unloading process cannot achieve accurate and quantitative unloading of the ingredients, and for soaked or washed ingredients, there is also the problem that waste water is difficult to collect.

[0025] In order to solve the above-mentioned technical problems, a device for quantitatively cutting food materials is proposed in the embodiment of the present invention. It should be noted that, in the embodiment of the present invention, the cutting-off shaft with a sinker is used to realize quantitative feeding of food materials. For this reason, the food materials can be powdery or granular food materials, and can be dry or wet. In order to achieve accurate quantification, the amount of feeding each time is controlled by the volume of the sink, so the inside of the sink must be clean, and the ingredients cannot be sticky or powdery, so as to avoid sticky ingredients sticki...

Embodiment 2

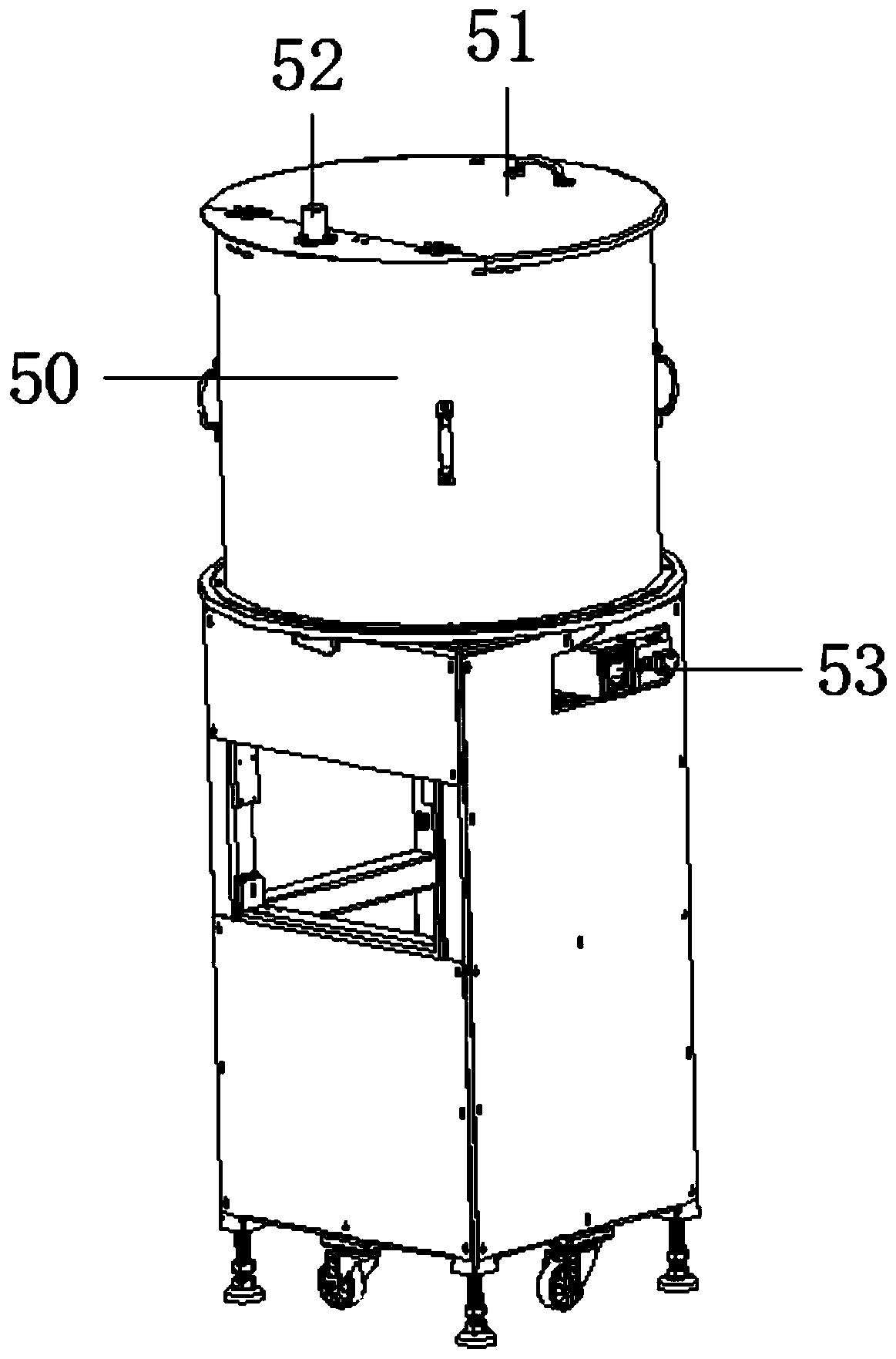

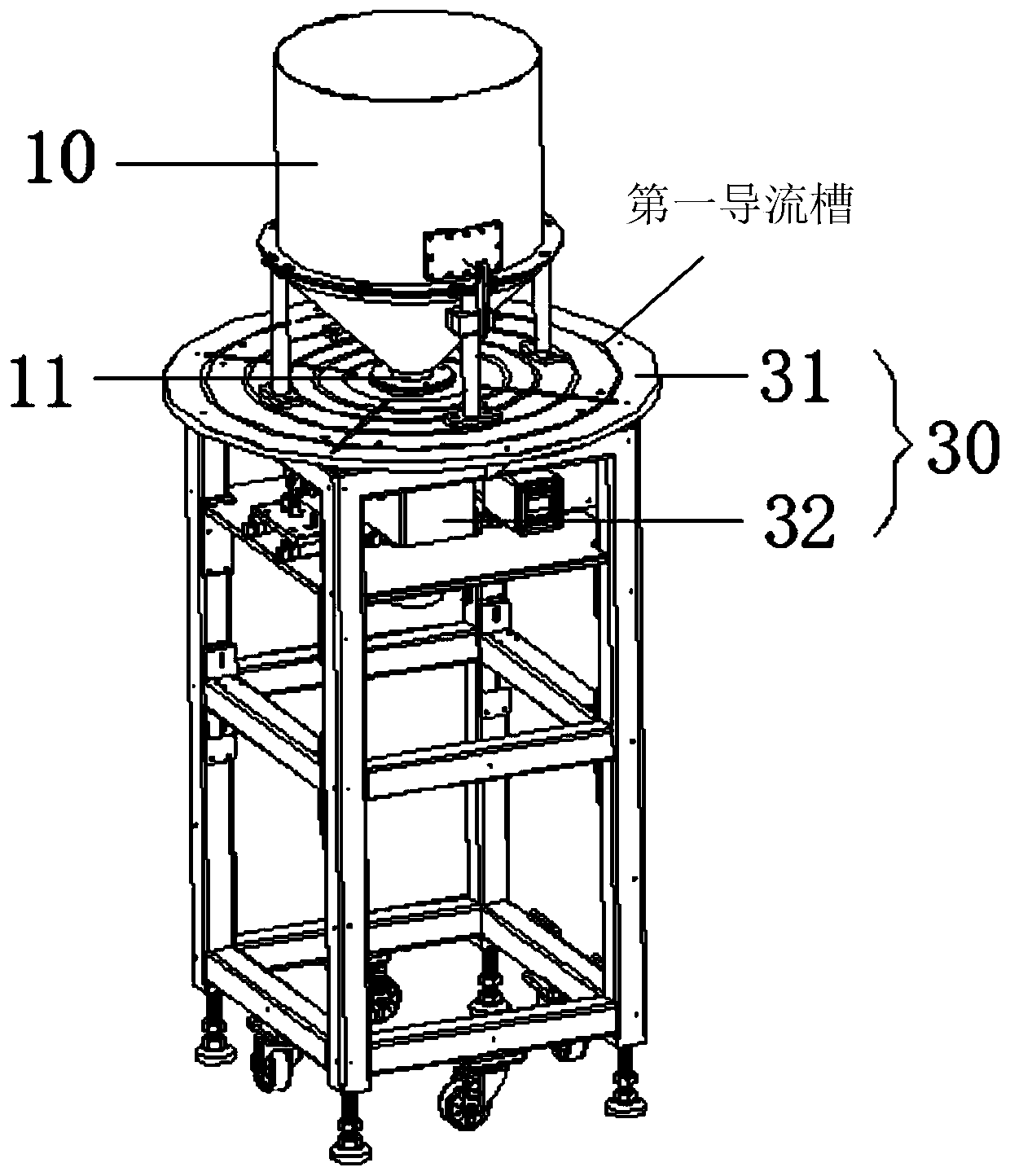

[0036] See Figure 1-4 , a rice quantitative cutting equipment provided in this embodiment also includes a storage bin 10 , a cutting shaft 20 and a water collecting device 30 . The storage bin 10 is used to store dried or soaked rice, the off-axis 20 is used to realize the quantitative feeding of rice, and the water collecting device 30 is used to collect waste water splashed from the rice.

[0037] Specifically, there is a rice pouring inlet at the top of the storage bin 10, and a feeding outlet 11 is formed at the bottom. The water collection device 30 includes a water collection pan 31 disposed below the storage bin 10 and a water collection tank 32 located below the water collection pan 31 and communicating with the lowest point of the water collection pan 31 .

[0038] The soaked rice is easy to deteriorate in high temperature environment and cannot be preserved for a long time. For this reason, as a further improvement of the technical solution, please refer to figure...

Embodiment 3

[0042] See Figure 1-4 , The rice quantitative cutting equipment provided in this embodiment includes a storage bin 10 , a cutting shaft 20 and a water collecting device 30 . The storage bin 10 is used to store dried or soaked rice, the off-axis 20 is used to realize the quantitative feeding of rice, and the water collecting device 30 is used to collect waste water splashed from the rice.

[0043] Specifically, there is a rice pouring inlet at the top of the storage bin 10, and a feeding outlet 11 is formed at the bottom. The cutting shaft 20 is rotatable and lies under the storage bin 10 , and the side wall fits with the feeding opening 11 . Its rotating drive part can be motor 40, and the end of cutting off shaft 20 is connected with motor 40 through coupling sleeve, realizes the linkage between motor 40 and cutting off shaft 20. On the cutting off axis 20, the position radially opposite to the feeding port 11 is provided with a sinking tank 21 whose volume is the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com