Automatic ball feeder

A ball machine, automatic technology, applied in grain processing and other directions, can solve the problems of poor accuracy, unstable transmission, ball jamming, etc., to prevent bunker and ball jamming, strong conveying stability, and reduce equipment loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

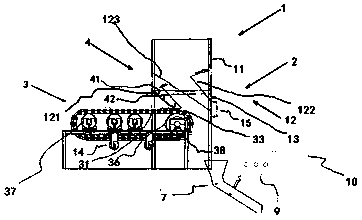

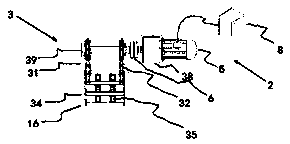

[0015] see Figure 1 to Figure 2 , these two figures provide the appearance overall structure of an embodiment of the automatic ball adding machine proposed by the present invention. The automatic ball adding machine includes a delivery assembly 1 and a drive assembly 2, wherein the delivery assembly 1 includes a ball storage box 11, a movable baffle 13, a transmission mechanism 3, and a barrier 4; the drive assembly includes a motor 5 and is arranged on the motor 5 and Coupling 6 between transmission mechanisms 3 .

[0016] The bottom of the ball storage box 11 is provided with a slideway 12 inclined at a certain angle, and the slideway 12 includes a main slideway 121 fixedly arranged on one side of the ball storage box and a main slideway 121 movably connected to the other side of the ball storage box through a flap 123 . Auxiliary slideway 122, and below the slideway 12 is installed the movable baffle 13 that is provided with roller 14 at the bottom end, is provided with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com