Planting sand prepared from straws

A straw and solid waste technology, applied in the field of planting sand, can solve the problems of strong dependence on the bonding effect of the binder, poor water and fertilizer retention performance, and short service life of the planting sand, so as to facilitate the fixing of plants and enhance fertilizer retention ability, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

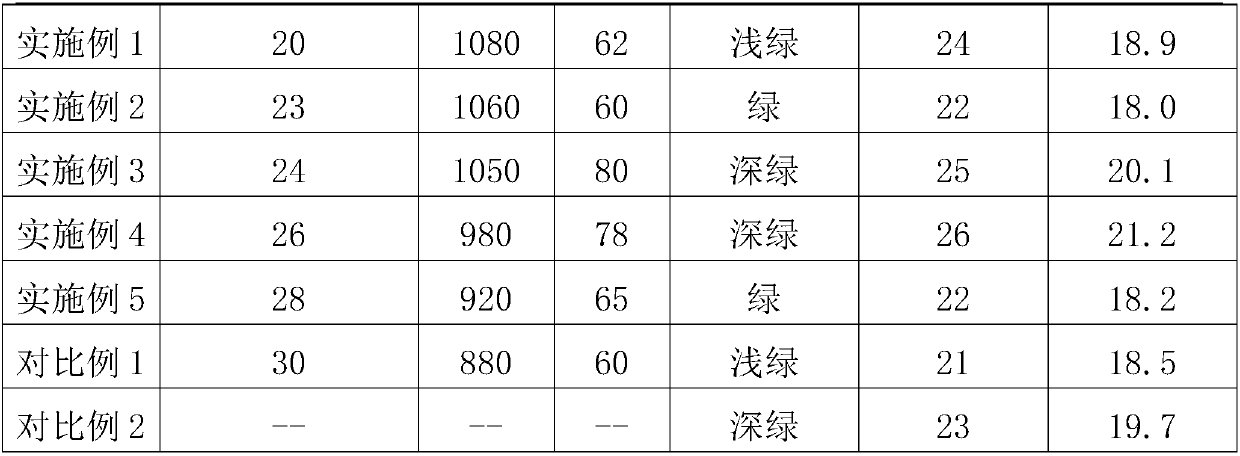

Examples

Embodiment 1

[0027] A planting sand prepared from straw, which is prepared from the following raw materials in parts by weight: 100 parts of fly ash, 5 parts of wheat straw, 5 parts of calcined kaolin, 1 part of quartz powder and 10 parts of water.

[0028] In this example, the planting sand prepared from straw was prepared by the following steps:

[0029] (1) Weigh 100 parts of fly ash, 5 parts of wheat straw, 5 parts of calcined kaolin, and 1 part of quartz powder, and place them in a mixer and mix them evenly to obtain a mixture;

[0030] (2) Pour the mixture and 10 parts of water in the step (1) into a high-speed granulator for granulation, and the rotating speed is 2000r / min;

[0031] (3) Put the granules made in step (2) into a drying oven for drying, and the drying temperature is 70° C.;

[0032] (4) Sinter the pellets dried in step (3) under anaerobic conditions. The sintering process is as follows: heat up to 300°C at 20°C / min, hold for 10 minutes, and then heat up to 700°C at 2°...

Embodiment 2

[0036] A planting sand prepared from straws, which is prepared from the following raw materials in parts by weight: 100 parts of coal gangue, 10 parts of rice straw, 5 parts of bentonite, 2.5 parts of silica fume, and 15 parts of water.

[0037] In this example, the planting sand prepared from straw was prepared by the following steps:

[0038] (1) Weigh 100 parts of coal gangue, 10 parts of rice straw, 5 parts of bentonite, and 2.5 parts of silica fume, place them in a mixer and mix them evenly to obtain a mixture;

[0039] (2) Pour the mixture and 15 parts of water in the step (1) into a high-speed granulator for granulation, and the rotating speed is 1500r / min;

[0040] (3) Put the granules made in step (2) into a drying oven for drying, and the drying temperature is 70° C.;

[0041] (4) Sinter the pellets dried in step (3) under low-oxygen conditions. The sintering process is as follows: heat up to 300°C at 25°C / min, hold for 10 minutes, and then heat up to 700°C at 2°C / m...

Embodiment 3

[0045] A planting sand prepared from straw, which is prepared from the following raw materials in parts by weight: 100 parts of slag, 10 parts of corn stalks, 5 parts of white mud, 5 parts of calcined kaolin, 1 part of quartz powder and 15 parts of water.

[0046] In this example, the planting sand prepared from straw was prepared by the following steps:

[0047] (1) Weigh 100 parts of slag, 10 parts of corn stalks, 5 parts of lime mud, 5 parts of calcined kaolin, and 1 part of quartz powder, and place them in a mixer and mix them evenly to obtain a mixture;

[0048] (2) Pour the mixture and 15 parts of water in the step (1) into a high-speed granulator for granulation, and the rotating speed is 3000r / min;

[0049] (3) Put the granules made in step (2) into a drying oven for drying, and the drying temperature is 80° C.;

[0050] (4) Sinter the pellets dried in step (3) under anaerobic conditions. The sintering process is as follows: heat up to 300°C at 40°C / min, hold for 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com