Combustor for gas stove

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and non-flammable liquid/gas transportation, etc. problem, to achieve the effect of increasing boundary conditions and combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

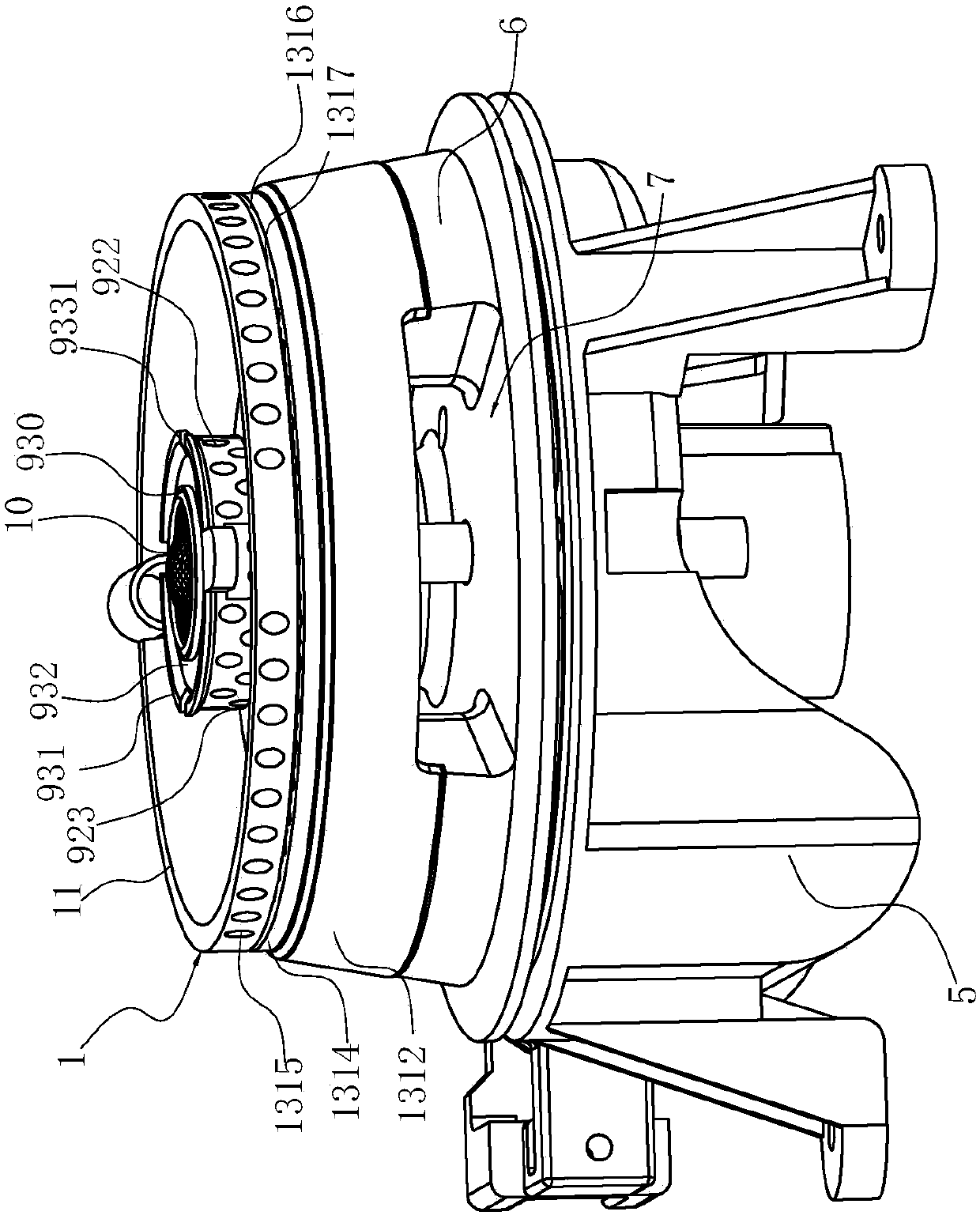

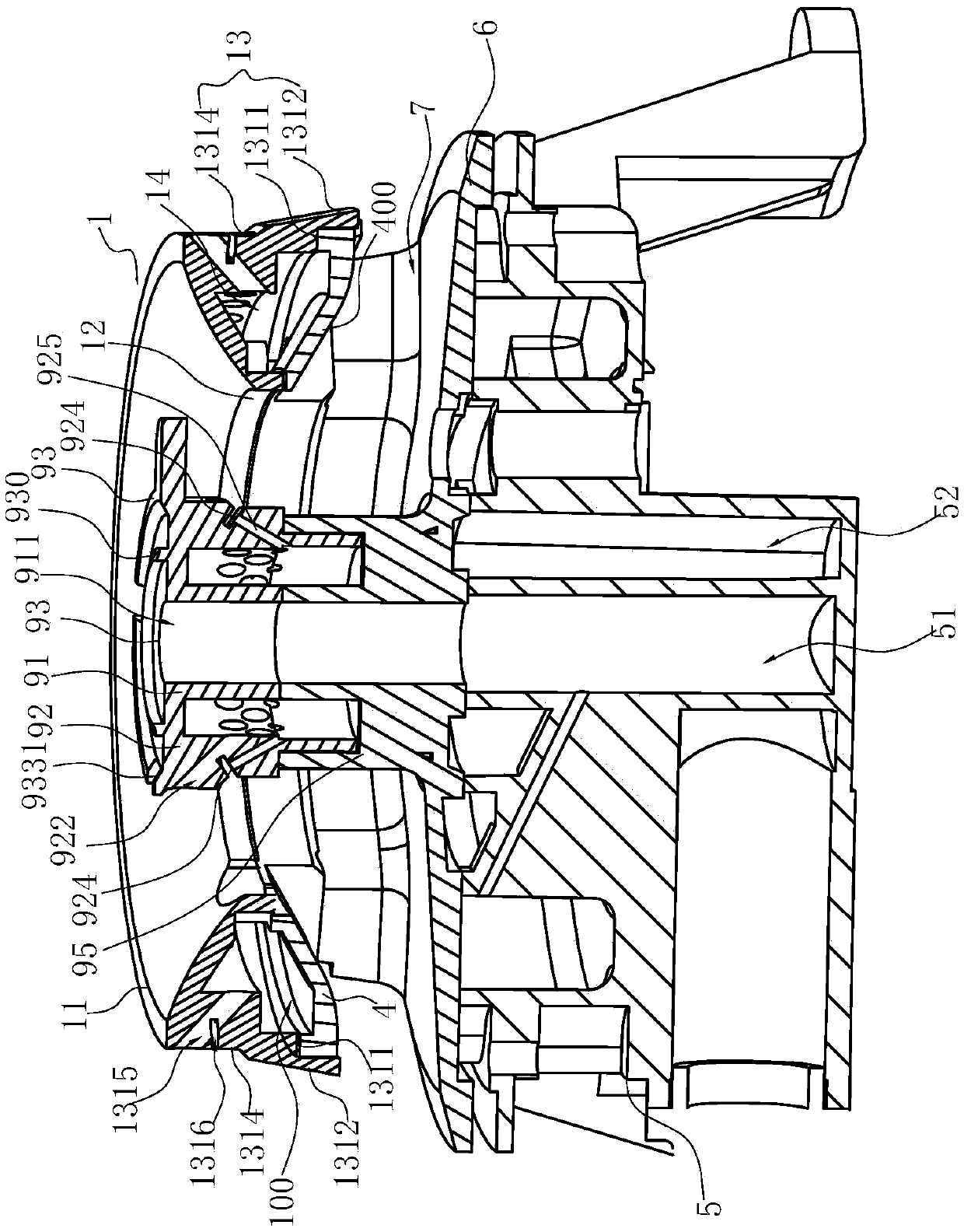

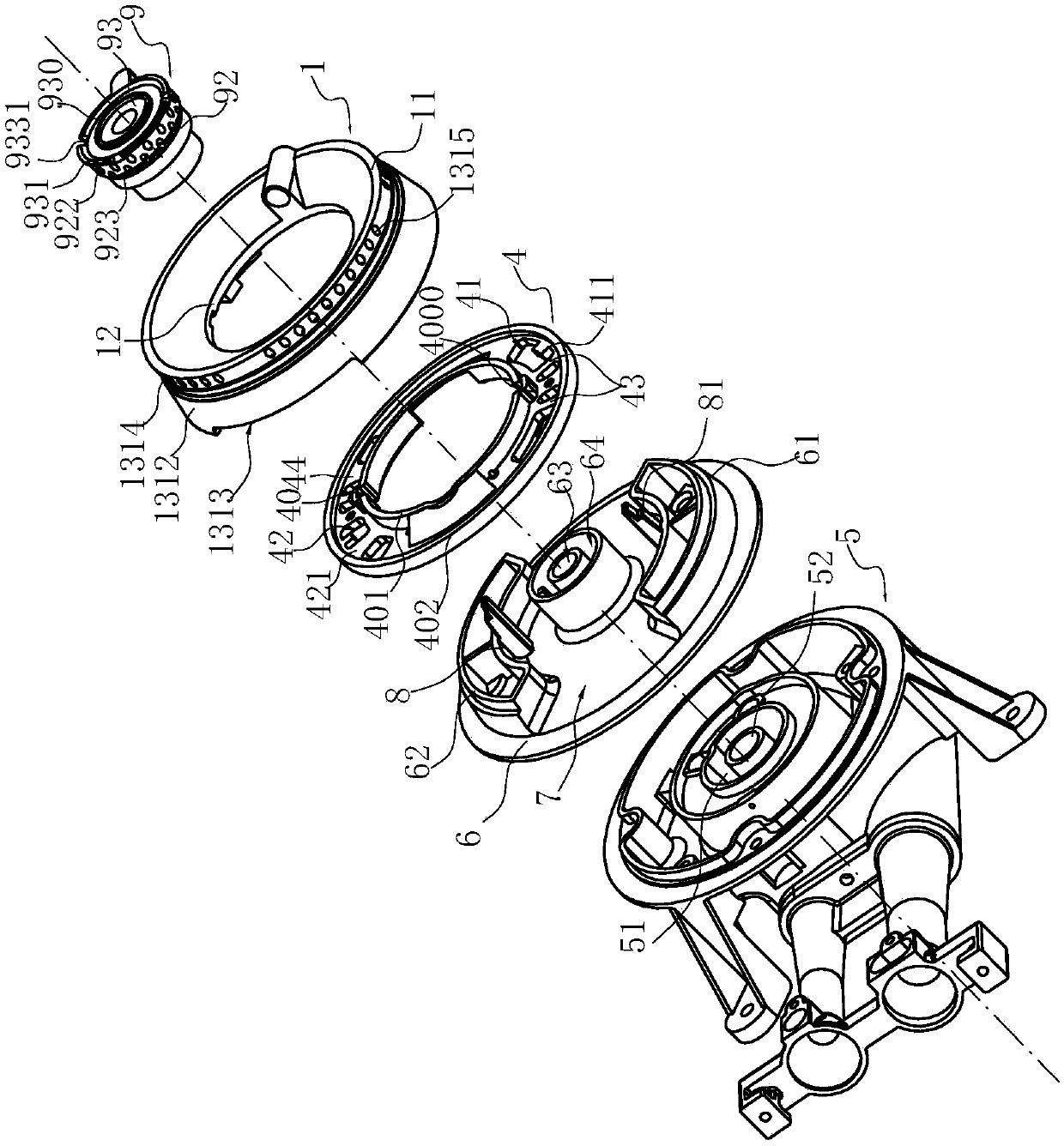

[0042] Such as Figure 1-10 Shown is the preferred embodiment of the present invention. In this embodiment, the burner used for the gas stove includes a first fire cover 1, and the first fire cover 1 includes a fire cover body, the annular top wall 11 of the fire cover body and the inner side A first air mixing chamber 14 is formed between the inner ring wall 12 and the outer ring wall 13 extending vertically downwards at the edge and the outer edge, and there are at least two first partitions 2 on the lower surface of the ring-shaped top wall 11 , There is a first distance D1 between adjacent first partitions 2, and a second partition 3 arranged on the lower surface of the annular top wall 11 and spaced apart from the first partition 2. In this embodiment, the first partition 2 and the second partition 3 are arranged oppositely, and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com