Spiral TiO2/graphene composite fiber and preparation method and application thereof

A graphene composite and helical technology, which is applied in the chemical characteristics of fibers, the preparation of spinning solutions, and the measurement of ultrasonic/sonic/infrasonic waves, etc. Simple and easy process, high sensitivity and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

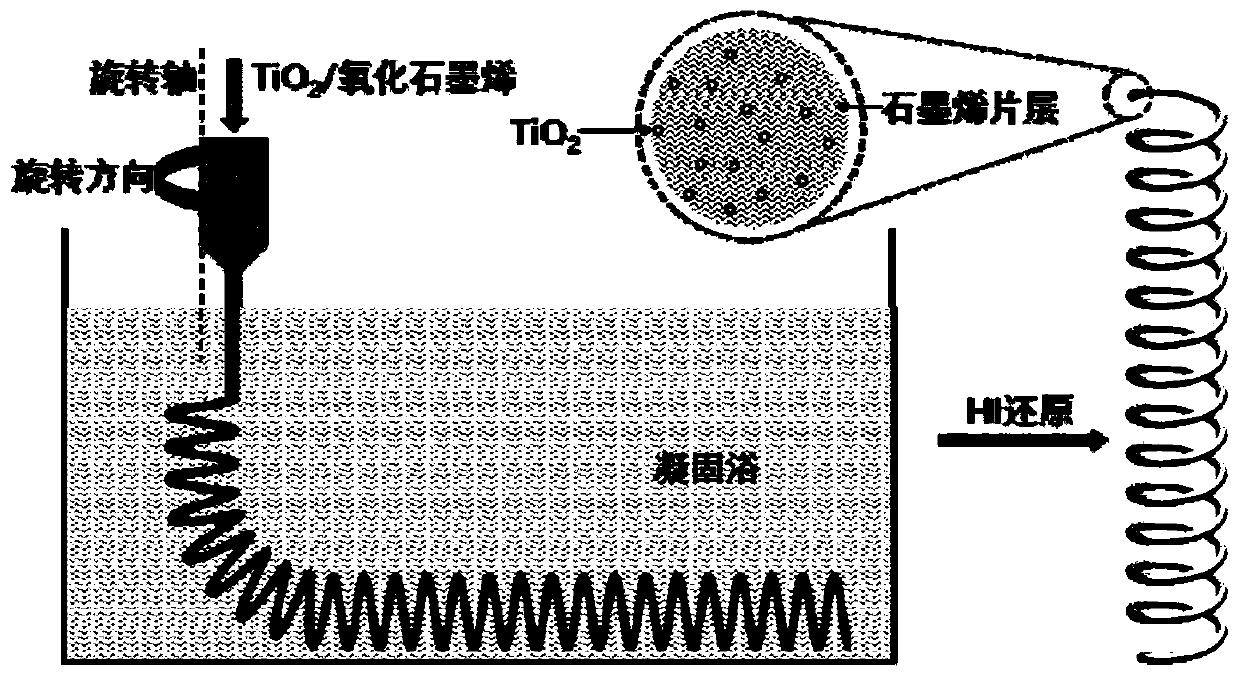

[0034] One aspect of the embodiments of the present invention provides a helical TiO 2 / The preparation method of graphene composite fiber, it comprises:

[0035] Provide a spinning solution comprising uniformly dispersed nano-titanium dioxide and / or nano-hydrogenated titanium dioxide and graphene oxide;

[0036] By wet spinning technology, the spinning solution is spun into helical TiO 2 / graphene oxide composite fiber;

[0037] The helical TiO 2 / Graphene oxide composite fiber reduction, then heating and setting to obtain helical TiO 2 / graphene composite fibers.

[0038] In some embodiments, the particle size of the nano-titanium dioxide and / or nano-hydrogenated titanium dioxide is 5-300 nm.

[0039] In some embodiments, the mass ratio of nano titanium dioxide and / or nano hydrogenated titanium dioxide to graphene oxide in the spinning solution is below 1:1.

[0040] Further, the number of layers of the graphene oxide is 2-10, and the sheet size is 4-150 μm.

[0041...

Embodiment 1

[0074] (1) Nano-titanium dioxide or hydrogenated nano-titanium dioxide with a particle size of 100nm and a graphene oxide dispersion liquid having 2-5 layers are mixed according to a mass ratio of 1:1 to prepare a spinning solution for subsequent use;

[0075] (2) Inject the spinning solution into figure 1 In the spinning device shown, with an injection speed of 15mm / s and a rotation speed of 48r / min, at a position of 3mm from the rotation axis, the helical TiO2 was prepared by wet spinning 2 / Graphite oxide composite ene fiber or helical H-TiO 2 / graphene oxide composite fiber;

[0076] (3) Helical TiO fixed on a glass rod of corresponding size by HI chemical reduction method 2 / graphene oxide composite fiber or helical H-TiO 2 / Graphene oxide composite fiber reduced to TiO 2 / graphene composite fiber or H-TiO 2 / graphene composite fiber, wherein the concentration of HI solution is 10wt%, and reduced at 90°C for 6h;

[0077] (4) the helical TiO 2 / graphene composite...

Embodiment 2

[0084] The conditions of this embodiment and embodiment 1 are basically the same, the difference is that the content of the added titanium dioxide is 10%, with the injection speed of 5mm / s and the rotation speed of 15r / min, the position of 3mm away from the rotation axis passes through the wet Spinning method, HI chemical reduction method adopts a temperature of 120°C and a time of 1h. The optical photo of the spring obtained after reduction annealing is shown in Figure 11 . Wherein, the annealing temperature is 400°C, and the annealing time is 6h. Finally, the fiber is used as the working electrode, and the liquid vibration of the three-electrode system is used for detection. For the results, please refer to Figure 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com