New technology for treating production wastewater generated from effective component extraction of coal tar

A technology for active ingredients and waste water production, applied in biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low treatment cost, air pollution, complex composition, etc., and achieve low and stable treatment cost The effect of meeting emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

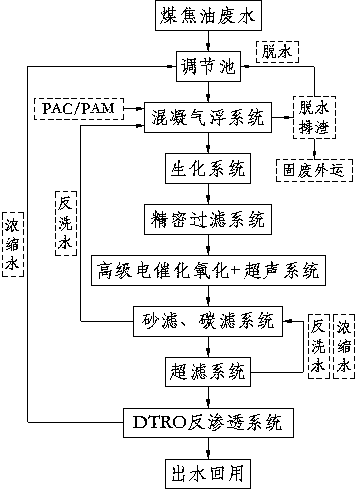

[0017] Such as figure 1 Shown, a kind of coal tar active ingredient extraction production wastewater treatment new technology, comprises the following steps:

[0018] (1) Pump the coal tar wastewater into the regulating tank, and keep stirring to make it evenly mixed;

[0019] (2) Send the uniformly mixed wastewater in step (1) to the coagulation air flotation system, and add PAC / PAM to it for flocculation, and use the dissolved air flotation to spray the flocs formed after adding the medicine with tiny air bubbles Lift it from the water body to the surface of the wastewater, and use a mechanical slag scraper to scrape the flocs from the surface of the wastewater and scrape them to the scum collection tank;

[0020] (3) Dehydrating the scum obtained after flocculation in step (2), wherein the dehydrated solid waste is transported outside, and the dehydrated waste water is sent back to the regulating tank;

[0021] (4) After the wastewater after flocculation in step (2) passe...

Embodiment 2

[0027] Such as figure 1 Shown, a kind of coal tar active ingredient extraction production wastewater treatment new technology, comprises the following steps:

[0028] (1) Pump the coal tar wastewater into the regulating tank, and keep stirring to make it evenly mixed;

[0029] (2) Send the uniformly mixed wastewater in step (1) to the coagulation air flotation system, and add PAC / PAM to it for flocculation, and use the dissolved air flotation to spray the flocs formed after adding the medicine with tiny air bubbles Lift it from the water body to the surface of the wastewater, and use a mechanical slag scraper to scrape the flocs from the surface of the wastewater and scrape them to the scum collection tank;

[0030] (3) Dehydrating the scum obtained after flocculation in step (2), wherein the dehydrated solid waste is transported outside, and the dehydrated waste water is sent back to the regulating tank;

[0031] (4) After the wastewater after flocculation in step (2) passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com