Sewage treatment method and special adjustment tank for same

A sewage treatment method and regulating tank technology, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of increasing maintenance costs of enterprises and increasing dosage , easily damaged inclined pipes and other problems, to achieve the effects of saving production costs and maintenance costs, balanced water quality, balanced and up-to-standard indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

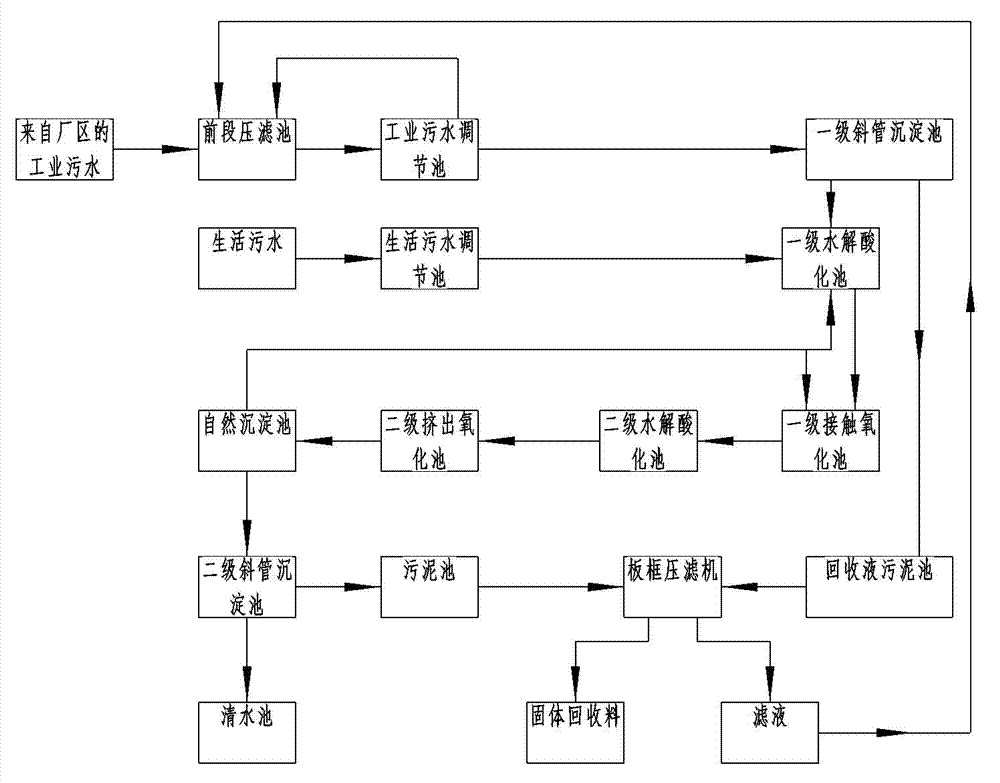

[0034] Embodiment 1: refer to figure 1 , is a process schematic diagram of Embodiment 1 of the present invention, comprising the following steps:

[0035] a. Sewage collection: collect the production sewage into the press filter tank;

[0036] b. Press filtration: In the press filter tank, the plate and frame filter press is used to perform pre-stage filter press treatment on the sewage to be treated, and the liquid obtained by the press filter is transported to the regulating tank, and the solid filter material obtained by the press filter is recovered;

[0037] c. Preliminary sedimentation: add sedimentation aiding agent in the adjustment tank, the aiding sedimentation agent contains one or more of flocculant, coagulant aid and neutralizing agent, and the dosage is flocculant (basic aluminum chloride): Concentration 8%, dosing amount 30mg / L; coagulation aid (PAM or polyacrylamide): concentration 1.0%, dosing amount 3mg / L; neutralizer (lime slurry): concentration 20%, dosing...

Embodiment 2

[0046] Embodiment 2: refer to figure 1 , is a process schematic diagram of Embodiment 1 of the present invention, comprising the following steps:

[0047] a. Sewage collection: collect the production sewage into the press filter tank;

[0048] b. Press filtration: In the press filter tank, the plate and frame filter press is used to perform pre-stage filter press treatment on the sewage to be treated, and the liquid obtained by the press filter is transported to the regulating tank, and the solid filter material obtained by the press filter is recovered;

[0049] c. Preliminary sedimentation: add sedimentation aiding agent in the adjustment tank, the aiding sedimentation agent contains one or more of flocculant, coagulant aid and neutralizing agent, and the dosage is flocculant (basic aluminum chloride): Concentration 8%, dosing amount 15mg / L; coagulation aid (PAM or polyacrylamide): concentration 0.7%, dosing amount 2.0mg / L; neutralizer (lime slurry): concentration 15%, dosi...

Embodiment 3

[0058] Embodiment 3: refer to figure 1 , is a process schematic diagram of Embodiment 1 of the present invention, comprising the following steps:

[0059] a. Sewage collection: collect the production sewage into the press filter tank;

[0060] b. Press filtration: In the press filter tank, the plate and frame filter press is used to perform pre-stage filter press treatment on the sewage to be treated, and the liquid obtained by the press filter is transported to the regulating tank, and the solid filter material obtained by the press filter is recovered;

[0061] c. Preliminary sedimentation: add sedimentation aiding agent in the adjustment tank, the aiding sedimentation agent contains one or more of flocculant, coagulant aid and neutralizing agent, and the dosage is flocculant (basic aluminum chloride): Concentration 9%, dosage 25mg / L; coagulation aid (PAM or polyacrylamide): concentration 0.5%, dosage 1.5mg / L; neutralizer (lime slurry): concentration 10%, dosage The amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com