Control system and method for fixed mold table intelligent maintenance unit

A maintenance unit and control system technology, applied in chemical instruments and methods, manufacturing tools, auxiliary molding equipment, etc., can solve problems such as heat loss from steam, surface cracking, and difficulty in ensuring product quality, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

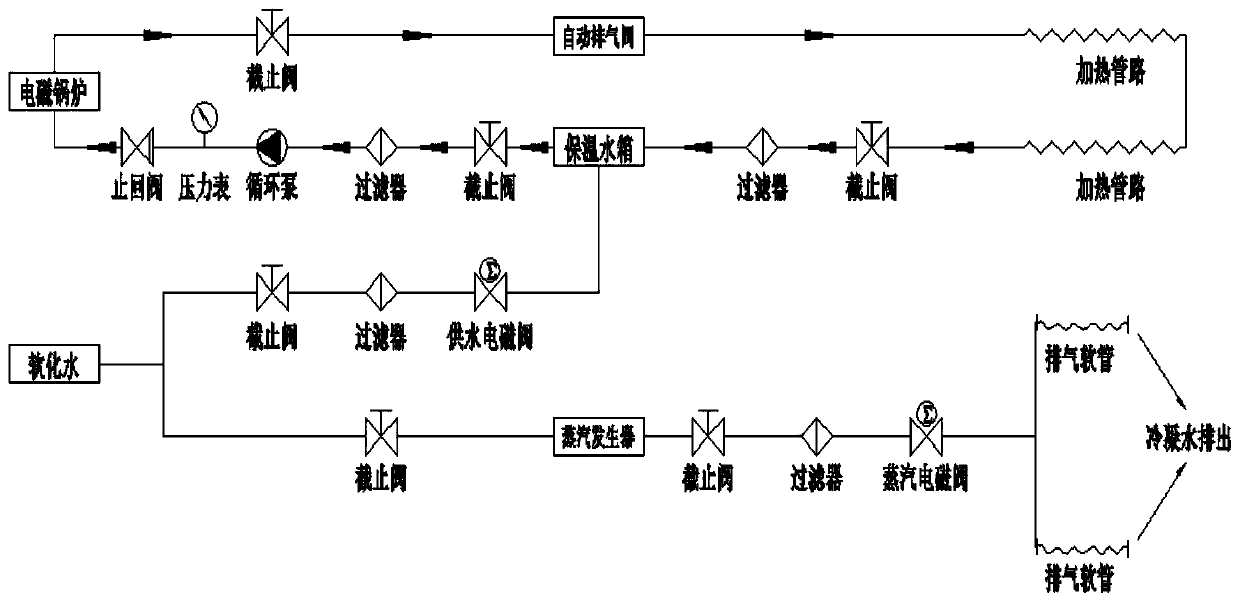

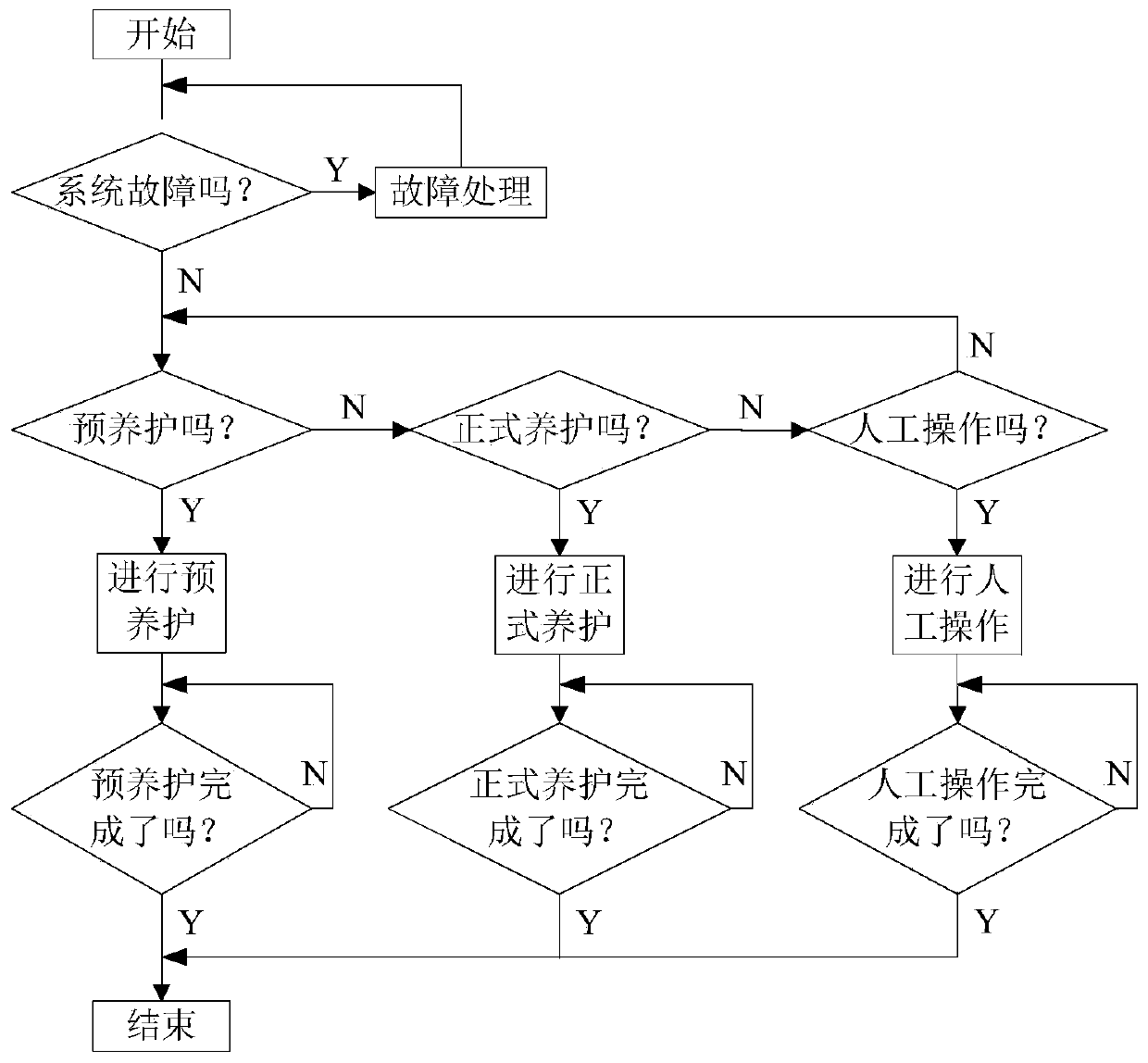

[0066] Such as Figure 1-2 As shown, an intelligent maintenance unit control system in an embodiment of the present invention includes a maintenance unit, a PLC controller, a human-computer interaction interface, a signal acquisition device, and a storage and printing device (not shown); the signal acquisition device includes: temperature and humidity sensors , liquid level gauge; the maintenance unit includes softened water equipment, electromagnetic boiler, steam generator, pipeline circulating water pump, water supply solenoid valve and steam solenoid valve; the human-computer interface is used for setting and inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com