Preparation method for covalent triazine framework compound and MoS2 compound hydrogen evolution catalyst and application of hydrogen evolution catalyst

A framework compound and triazine technology, applied in the field of catalyst preparation, can solve the problems of high price, lack of platinum resources, and poor development of platinum catalysts, and achieve low cost, abundant pores, accelerated mass transfer and charge transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Covalent Triazine Skeleton Compound and MoS 2 Preparation method of composite hydrogen evolution catalyst

[0031] In this implementation, proceed in the following order of steps:

[0032] (1) The preparation of the covalent triazine skeleton compound comprises the following steps carried out in sequence:

[0033] A1) Add anhydrous zinc chloride and terephthalonitrile into the container and mix them into a heat-resistant glass tube, then use a vacuum pump to remove oxygen, keep it for 8 minutes, use a vacuum pump to remove air, and use an alcohol blowtorch to remove the oxygen. Sealed heat-resistant glass tube.

[0034] A2) Put the sealed heat-resistant glass tube into a tube furnace, heat it at room temperature to 400° C. at a constant speed, keep it for 40 hours, then cool to room temperature, open the container, and obtain mixture A.

[0035] A3) Mixture A was ground into powder, washed 5 times with deionized water, then added with 0.1 mol / L dilute hydro...

Embodiment 2~8

[0040] Examples 2-8 Covalent triazine skeleton compound and MoS 2 Preparation method of composite hydrogen evolution catalyst

[0041] Examples 2-8 are respectively a covalent triazine skeleton compound and MoS 2 The preparation method of the composite hydrogen evolution catalyst, the preparation method is the same as the preparation method of Example 1, the difference is that the reaction conditions involved in each step, the substances used and the consumption are different, see Table 1 for details

[0042] Table 1

[0043]

Embodiment 9

[0044] Example 9 Covalent Triazine Skeleton Compound and MoS2 Application of hydrogen evolution catalyst

[0045] This embodiment provides a method using any one of the covalent triazine skeleton compounds in Examples 1 to 8 and MoS 2 Covalent triazine skeleton compound and MoS prepared by the preparation method of composite hydrogen evolution catalyst 2 The application of the composite hydrogen evolution catalyst, which is used as a catalyst in the industrial electrocatalytic hydrogen evolution reaction to prepare hydrogen.

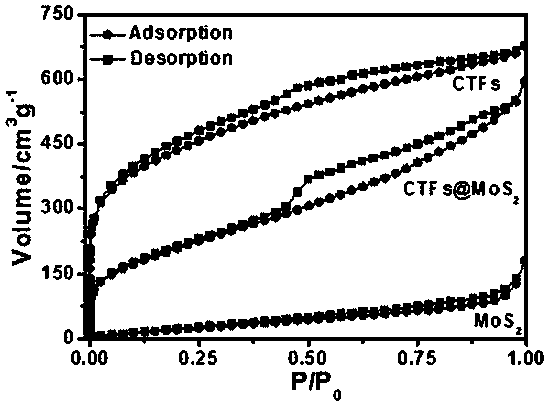

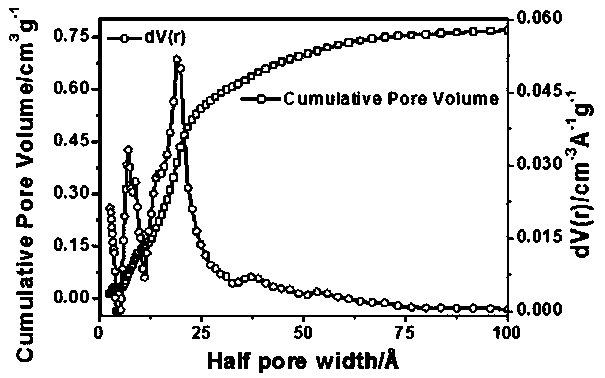

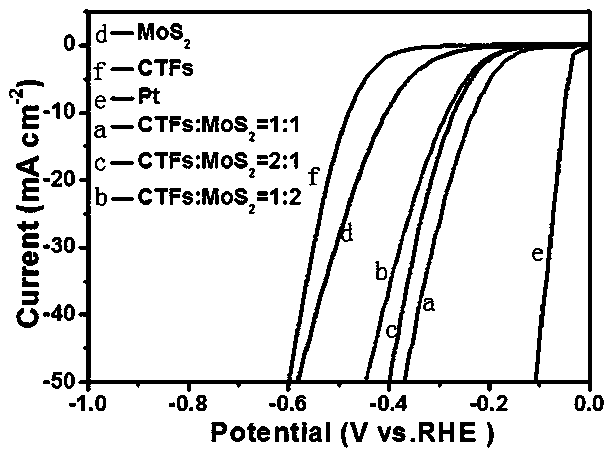

[0046] The covalent triazine skeleton compound obtained in Examples 1-8 and MoS 2 MoS in Composite Hydrogen Evolution Catalyst 2 : The mass ratio of the covalent triazine skeleton compound A is 1:1. When it is applied to the electrocatalytic hydrogen evolution reaction, the linear scanning curve of the performance is as follows figure 2 As shown in the curve a of , at the same time, this example also obtained MoS by changing the amount of ammonium mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com