Polypropylene thin film capacitance end cover explosion-proof pressure measuring device

A polypropylene film, explosion-proof pressure technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of long destructive test time, waste, batch scrapping, etc., to ensure safety performance and reliability, improve measurement accuracy, and reduce cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

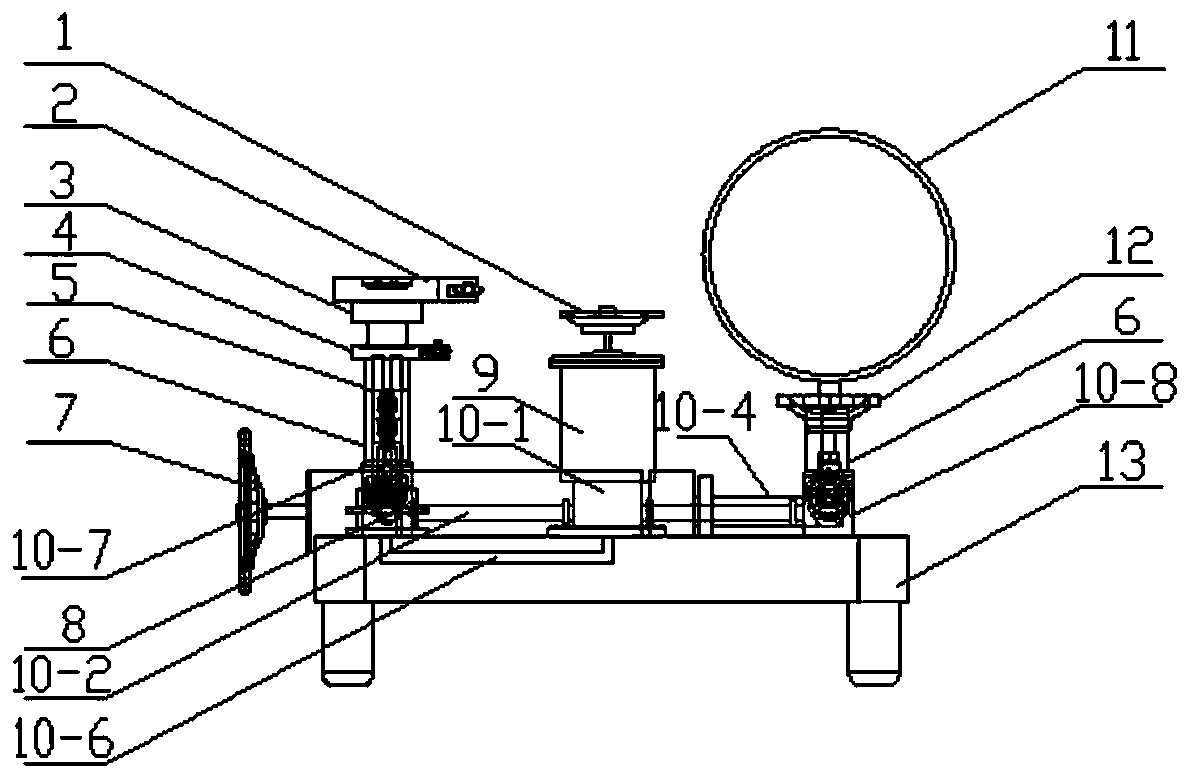

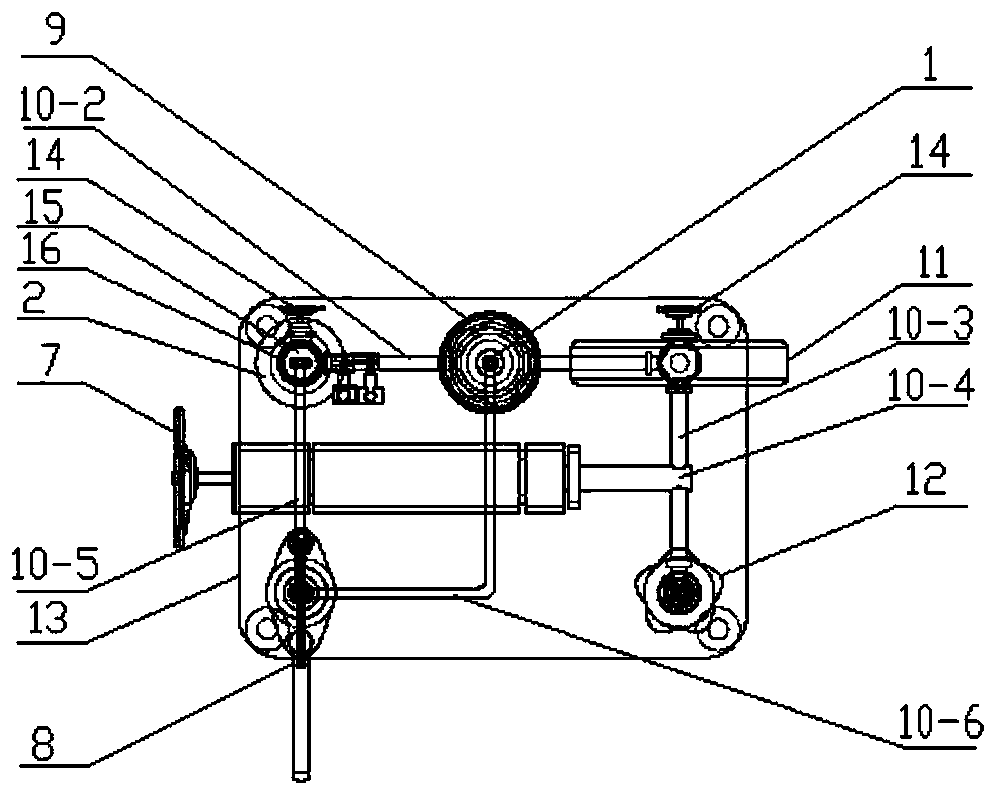

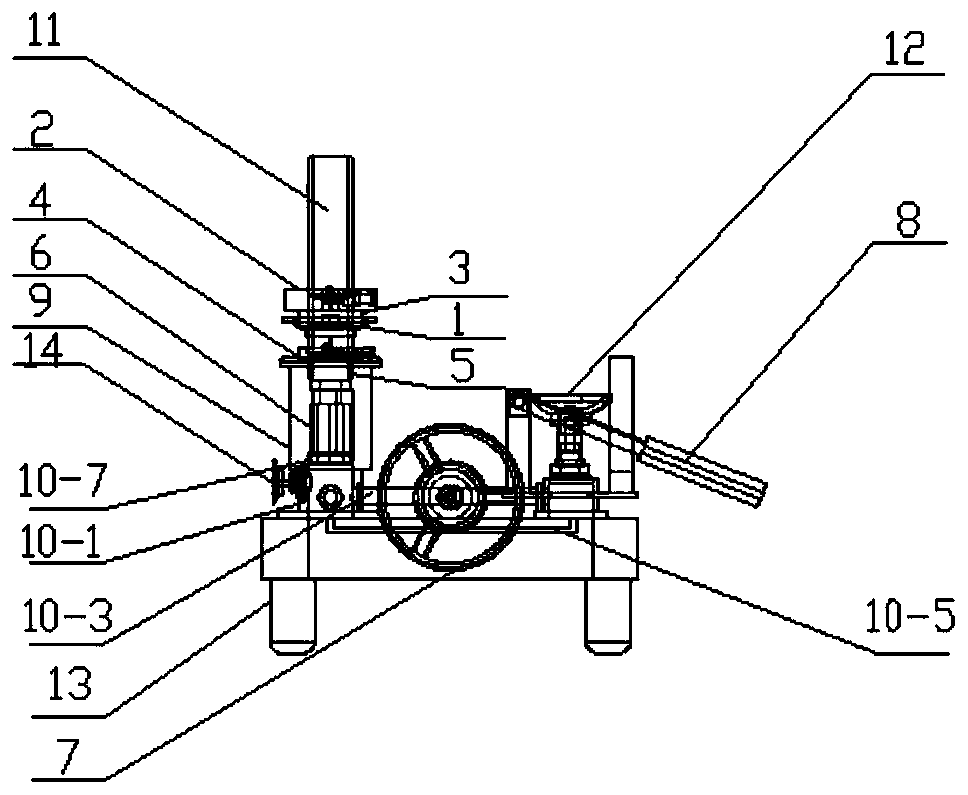

[0029] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0030] Such as Figure 1-Figure 4As shown in the figure, a new type of polypropylene film capacitor end cover explosion-proof pressure gauge consists of an oil cup valve 1, an upper hoop 2, an oil pressure groove 3, a lower hoop 4, a connecting bottom bracket 5, a one-way valve 6, a manual Shaker pump 7, hand pump 8, oil cup 9, first connecting conduit 10-1, second connecting conduit 10-2, first connecting conduit 10-3, first connecting conduit 10-4, fifth connecting conduit 10 -5. Sixth connecting conduit 10-6, seventh connecting conduit 10-7, eighth connecting conduit 10-8, precision pressure gauge 11, shut-off valve 12, base 13, needle valve 14, end cap to be tested 15, Hollow pressing sheet 16, sealing ring 17, gasket 18 and other parts constitute. All metal parts are designed to be made of stainless steel, which is anti-corrosion and anti-rust, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com