A dry low-pollution combustor double radial swirl nozzle for a gas turbine

A gas turbine and swirl nozzle technology, which is applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of fouling of turbine blades, large axial size requirements and high cost, and achieves refined mixing scale, processing Low difficulty and enhanced uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

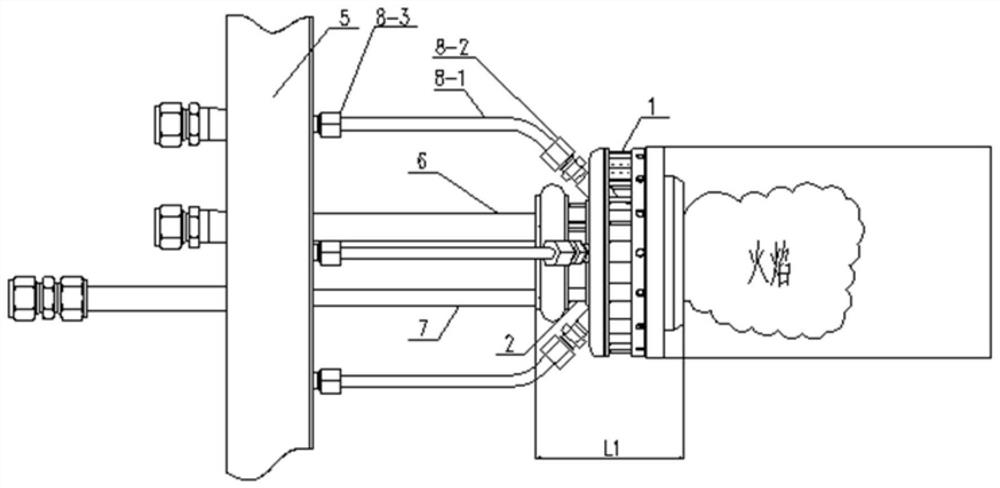

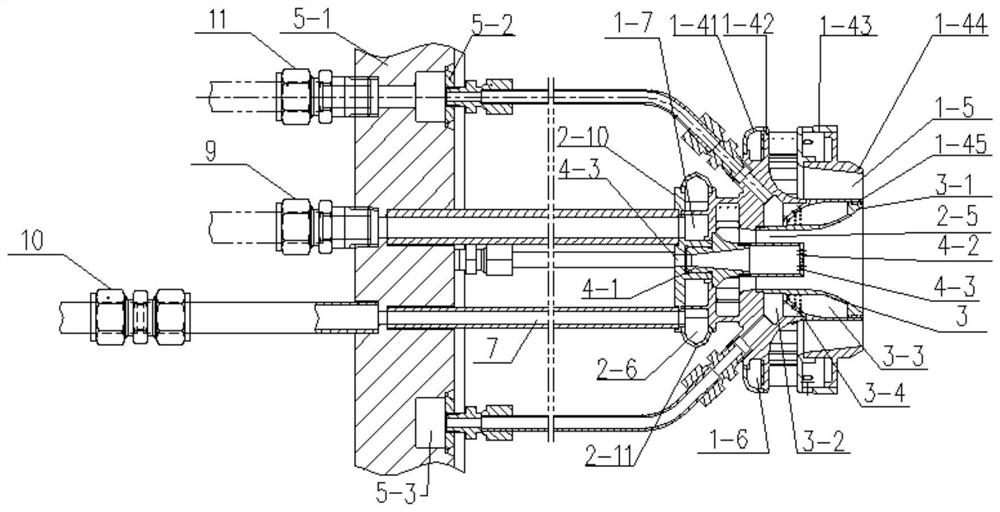

[0027] Specific implementation method: as attached Figure 1-5 As shown, this embodiment provides a dry-type low-pollution combustor double radial swirl nozzle for a gas turbine, including an outer swirler assembly 1, an inner swirler assembly 2, a diffusion combustion / cooling assembly 3, and a central purge Assembly 4 , end cap 5 , first pipe piece 6 , second pipe piece 7 , third pipe piece 8 , outer premix fuel fitting 9 , inner premix fuel fitting 10 and diffusion fuel fitting 11 .

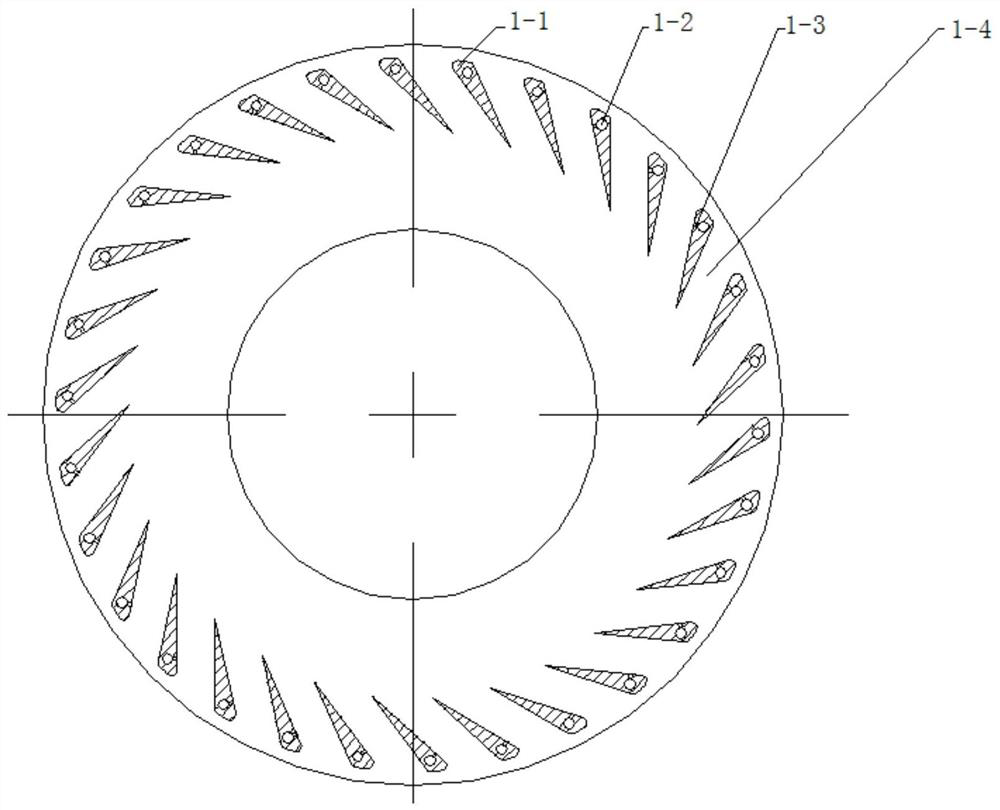

[0028] The outer swirler assembly 1 includes a swirler body 1-42, an outer holder for the outer swirl blades 1-43, an outer casing of the mixing section 1-44, a casing of the fuel chamber 1-41 and an inner casing of the premixing section 1-45; the cyclone body 1-42 includes N branches of external swirl blades 1-1, and the N branches of external swirl blades 1-1 are evenly arranged around the center line of the cyclone body 1-42; The outer swirl vane 1-1 divides the radial channel formed by the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com