Multi-functional mixed transportation pump

A mixed-infusion pump and multi-functional technology, applied in the field of multi-functional mixed-infusion pumps, can solve the problems of easy air lock, high medium state requirements, poor power output stability, etc., to improve reliability and stability, and operation adaptability Strong, de-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

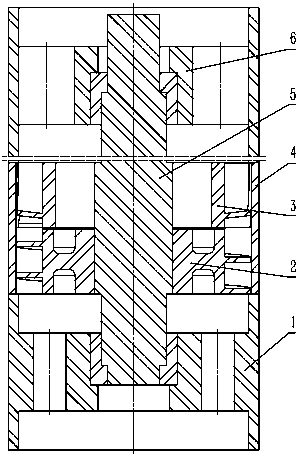

[0040] refer to Figure 1 to Figure 4 As shown, a multifunctional mixed pump includes a pump barrel 4 , a pump shaft 5 , a suction head 1 and a discharge head 6 .

[0041] The lower end of the pump barrel 4 is connected to the suction head 1, and the upper end of the pump barrel 4 is connected to the discharge head 6. The cavity of the pump barrel 4 is provided with a guide wheel 3 and an impeller 2 sequentially from top to bottom. end contact.

[0042] The suction head 1, the discharge head 6, the impeller 2 and the guide wheel 3 are all provided with shaft holes adapted to the pump shaft 5, and the shaft holes on the suction head 1, the discharge head 6, the impeller 2 and the guide wheel 3 are all aligned with the pump shaft. The cylinder 4 is located on the same axis, and the pump shaft 5 passes through the cavity of the pump cylinder 4 along the axis of the pump cylinder 4, and passes through the shaft holes of the suction head 1, the guide wheel 3, the impeller 2 and th...

Embodiment 2

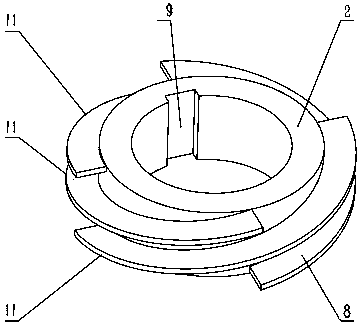

[0055]In this embodiment, on the basis of Embodiment 1, the combination of one impeller 2 and one guide wheel 3 is set as a set of power mechanisms, and multiple sets of power mechanisms are stacked and assembled on the pump shaft 5 .

[0056] During assembly: the upper end surface of the impeller 2 in the same group of power mechanisms is in contact with the lower end surface of the adjacent guide wheel 3, and the upper end surface of one set of guide wheels 3 in the adjacent two sets of power mechanisms is in contact with the lower section of the other set of impeller 2, It can be realized by repeated superposition. According to the difference of the output power of the pump, the height of the pump barrel 4 can be increased to install a power mechanism combining the 1-700-stage impeller 2 and the guide wheel 3, and drive multiple sets of power through a single pump shaft 5. The impeller 2 in the mechanism rotates, so that the present invention has the characteristics of high ...

Embodiment 3

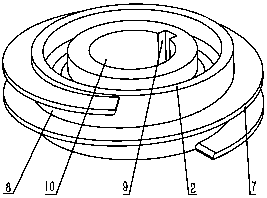

[0060] In this embodiment, on the basis of Embodiment 1, the number of longitudinal guide vanes 12 arranged on the outer circumference of the guide wheel 3 is specifically 4-20 pieces, and the guide vanes 12 are equally spaced around the outer circumference of the guide wheel 3;

[0061] The guide vane 12 presents a curved surface that smoothly transitions from a curved section to a straight section from the guide inlet end 14 to the guide outlet end 15, and the curved surface faces the direction of the outlet of the spiral flow channel 8, thereby facilitating the flow direction of the fluid and making it easier for the fluid to leave the spiral flow channel 8 and then directly into the longitudinal fluid passage 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com