Method for performing backfilling and hydraulic ramming on stage back of bridges and culverts

A bridge and culvert, hydraulic technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of low compaction quality, increased construction costs, slow construction progress, etc., to ensure compaction quality, save construction costs, The effect of reducing the amount of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

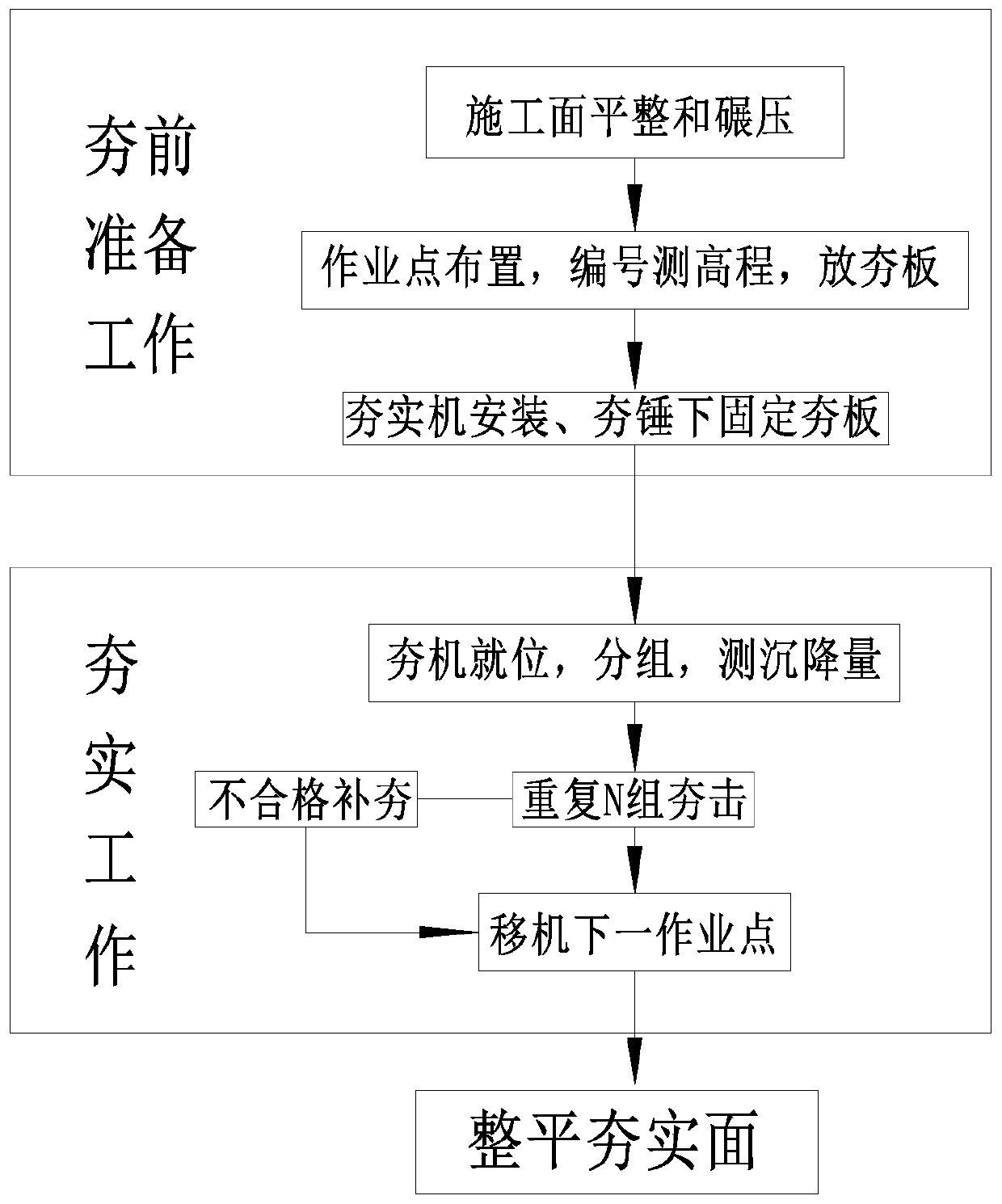

[0031] Such as figure 1 Shown, the present invention selects the backfill layer of sandy soil and fine-grained soil, comprises the following steps:

[0032] Step 1. Preparatory work before tamping:

[0033] A1. The construction surface must be leveled with a bulldozer before tamping, and then rolled by a road roller, and inspected according to the compaction standards and flatness required by the design, and repeated leveling and rolling for the construction surface that does not meet the design requirements until it meets the design It is required that when the construction surface is relatively dry, it is necessary to spray an appropriate amount of water to prevent the surface from becoming dusty, which will affect the transfer of energy to the deep layer;

[0034] A2. Release the operating points on the construction surface after passing the inspection. When laying out the operating points, the gap-type operating points are arranged. The gap-type operating points are arran...

Embodiment 2

[0045] The difference from Example 1 is that when the backfill layer of gravel and granular soil is selected, due to the small deformation of the gravel and granular soil, the gap-type arrangement operation points in step A2 are 30cm apart from the edge of each operation point, and are arranged in an equilateral triangle. , the distance between the working point on the side near the back of the platform and the back of the platform is 50cm; in step B1, repeat 5 groups, and in step B2, when the difference in relative settlement between the fifth group and the fourth group is less than 10mm, stop at this point According to the construction, the compaction coefficient within the depth range of 1m below the construction surface is 0.94, and the K30 value is 134Mpa / m.

Embodiment 3

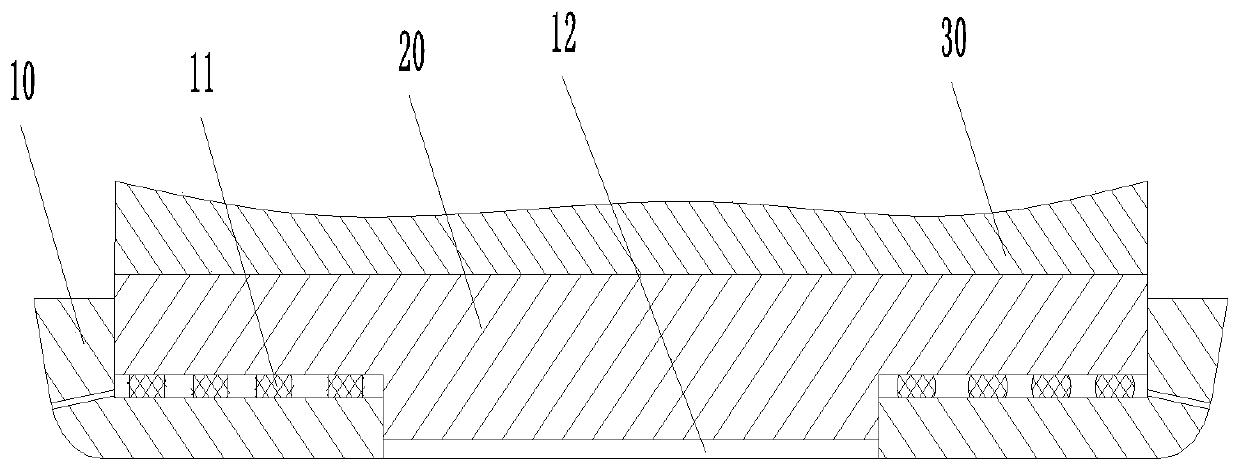

[0047] Such as figure 2 As shown, on the basis of Embodiment 1, the following improvements have been made: the ramming plate includes a first ramming plate 10 and a second ramming plate 20, the first ramming plate 10 is a conical structure, and the middle part of the first ramming plate 10 is provided with Step hole 12, buffer pad 11 on the step surface of step hole 12, the cross-section of the second tamping plate 20 is T-shaped, the second tamping plate 20 is sleeved in the step hole 12, the top surface of the second tamping plate 20 and the rammer 30 is fixedly connected and the thickness of the second tamping plate 20 is equal to the sum of the thickness of the first tamping plate 10 and the deformation of the buffer pad 11 . When the rammer hits, the second ramming plate 20 first moves downward, and the second ramming plate 20 then transmits the force to the first ramming plate 10 through the buffer pad 11, and the deformation process of the first ramming plate 10 occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com