Adhesive for high-density wear-resistant environment-friendly tires and preparation method thereof

An adhesive and dense technology, which is applied in the field of adhesives for high-density wear-resistant and environmentally friendly tires and its preparation, can solve the problems of not being able to balance quality and environmental protection, achieve green environmental protection in the production process, improve tear strength, The effect of enhancing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

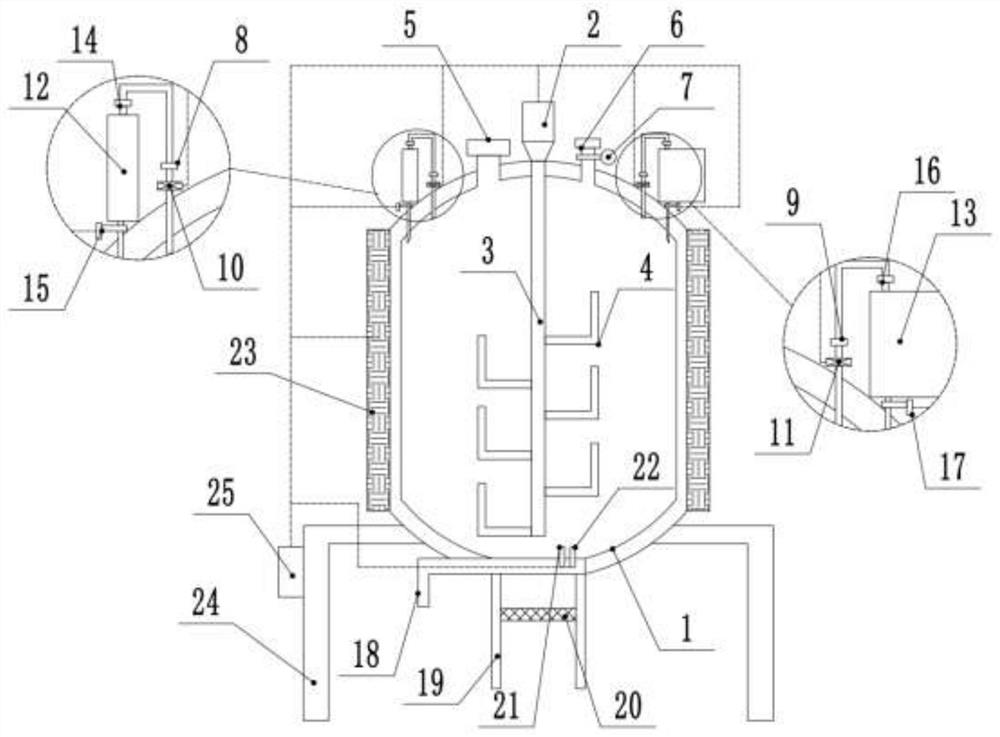

Image

Examples

Embodiment 1

[0033] A high-density wear-resistant type adhesive for environment-friendly tires, comprising:

[0034] 250 parts of hexamethylolmelamine;

[0035]40 parts of di-tert-butylbenzothiazole;

[0036] 10 parts of internal lubricants, which are any one or more of stearic acid, calcium stearate or fatty acid lower alcohol esters. The internal lubricant can reduce the cohesion between polymer molecules inside the polymer, further control the degree of polymerization of reactants, and prevent the gel phenomenon caused by self-polymerization.

[0037] 60 parts of film-forming compound, the film-forming compound is composed of hydroxypropyl methylcellulose, arabinose, polyvinyl alcohol and starch according to the mass ratio of 3:1:2:2. All film-forming compounds are hydroxyl-containing polymers. By adding film-forming compounds to form film layers on the inside and outside of the original adhesive, the bonding strength and aging resistance of the adhesive can be further improved.

[0...

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, the difference is:

[0057] A high-density wear-resistant type adhesive for environment-friendly tires, comprising:

[0058] 200 parts of hexamethylolmelamine;

[0059] 50 parts of di-tert-butylbenzothiazole;

[0060] 8 parts of internal lubricant, the internal lubricant is stearic acid, the internal lubricant can play a role in reducing the cohesion between polymer molecules inside the polymer, further control the degree of polymerization of the reactant, and prevent the gel produced by self-polymerization Phenomenon.

[0061] 50 parts of film-forming compound, the film-forming compound is composed of hydroxypropyl methylcellulose, arabinose, polyvinyl alcohol and starch according to the mass ratio of 3:1:2:2. All film-forming compounds are hydroxyl-containing polymers. By adding film-forming compounds to form film layers on the inside and outside of the original adhesive, the bonding strength and aging resistan...

Embodiment 3

[0076] This embodiment is basically the same as Embodiment 1, the difference is:

[0077] A high-density wear-resistant type adhesive for environment-friendly tires, comprising:

[0078] 220 parts of hexamethylolmelamine;

[0079] 45 parts of di-tert-butylbenzothiazole;

[0080] 9 parts of internal lubricant, described internal lubricant is calcium stearate, and internal lubricant can play the effect of reducing the cohesive force between polymer molecules inside the polymer, further controls the polymerization degree of reactant, prevents the coagulation that self-polymerization produces glue phenomenon.

[0081] 55 parts of film-forming compound, the film-forming compound is composed of hydroxypropyl methylcellulose, arabinose, polyvinyl alcohol and starch according to the mass ratio of 3:1:2:2. All film-forming compounds are hydroxyl-containing polymers. By adding film-forming compounds to form film layers on the inside and outside of the original adhesive, the bonding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com