Tank-wall heat tracing dirty oil sedimentation method and device

A settling device and technology for dirty oil, applied in the direction of separation method, grease/oily substance/suspended substance removal device, chemical instrument and method, etc., can solve unfavorable gravity settlement, poor separation effect of sewage oil settlement, and inconspicuous dehydration effect, etc. problem, to achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention discloses a tank wall heat tracing method for settling dirty oil. Specifically, the heat tracing method is evenly arranged from top to bottom along the height of the tank, and the temperature of the heat tracing medium is controlled to be less than 100°C, so as to achieve three-phase separation of oil, water, and slag of the waste oil.

[0031] The heating medium is heat medium water.

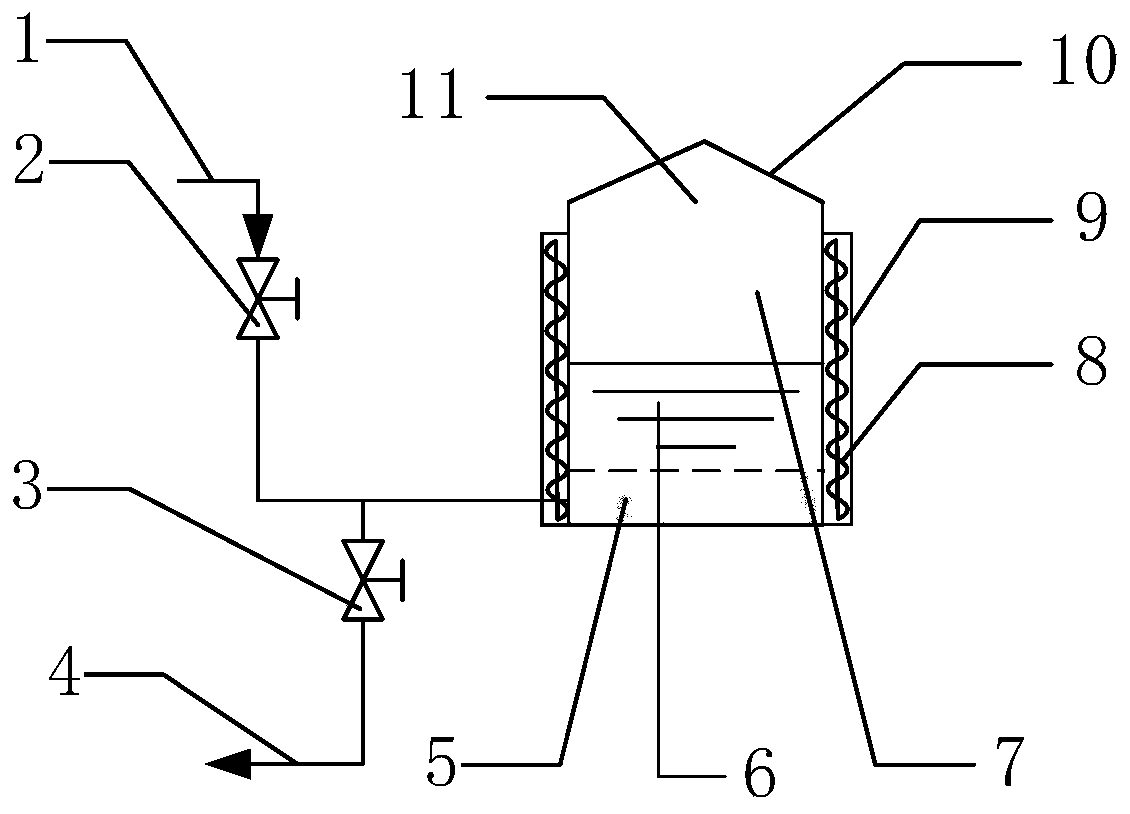

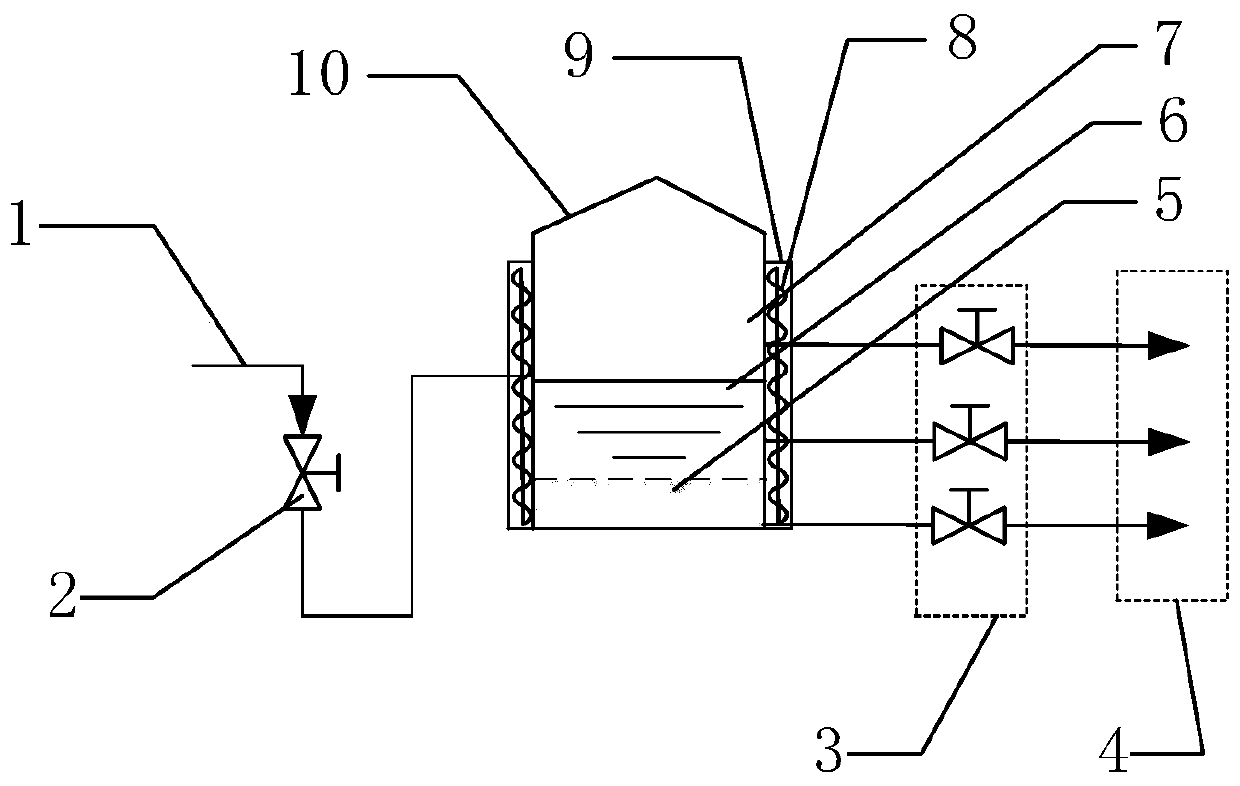

[0032] A tank wall heating type sewage oil settling device, comprising a feed sewage oil pipeline 1, a feed sewage oil pipeline 1 connected to a feed switch valve 2 through a pipeline, and a feed switch valve 2 connected to a settling tank 11 through a pipeline The settling tank 11 includes a tank body 10, the upper part of the tank body 10 is a cone, and the lower part is a cylinder. The heating line 8 is arranged outside the lower cylinder of the tank body 10, and the heat insulation layer 9 is arranged outside the heating line 8.

[0033] The heating line 8 is arranged e...

Embodiment 2

[0047] The invention relates to a method for settling waste oil with heat tracing on the tank wall. The heat tracing method is evenly arranged from top to bottom along the height of the tank, and the temperature of the heat tracing medium is controlled to be less than 100°C, so as to achieve the three-phase separation of oil, water, and slag of the waste oil.

[0048] The tank wall heating type sewage oil settling device used in Example 2 is the same as that in Example 1.

[0049] A kind of tank wall heating type sewage oil settling device, refer to figure 1 method, transforming the 200L settling tank, and evenly installing silica gel electric heating cables from bottom to top along the tank wall, and settling and separating the dirty oil that could not be effectively separated in Comparative Example 1, settling at 90°C for 5 days, and separating the oil and water slag The effect is obvious. Divide 10 sampling points equally along the height of the settling tank, and analyze ...

Embodiment 3

[0051] The invention relates to a method for settling waste oil with heat tracing on the tank wall. The heat tracing method is evenly arranged from top to bottom along the height of the tank, and the temperature of the heat tracing medium is controlled to be less than 100°C, so as to achieve the three-phase separation of oil, water, and slag of the waste oil.

[0052] A tank wall heating type sewage oil settling device, comprising a feed sewage oil pipeline 1, a feed sewage oil pipeline 1 connected to a feed switch valve 2 through a pipeline, and a feed switch valve 2 connected to a settling tank 11 through a pipeline The settling tank 11 includes a tank body 10, the upper part of the tank body 10 is a cone, and the lower part is a cylinder. The heating line 8 is arranged outside the lower cylinder of the tank body 10, and the heat insulation layer 9 is arranged outside the heating line 8.

[0053] The heating line 8 is arranged evenly from bottom to top along the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com