Automobile tail gate assembly and process technology thereof

A tailgate and automobile technology, which is applied in the direction of connection between vehicle components, doors, and upper structure subassemblies, can solve the problems of complex stamping process, overall rigidity reduction, and durability decline of the rear tailgate cover, and achieve The effects of beautiful and diverse shapes, weight reduction, and avoidance of complexity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

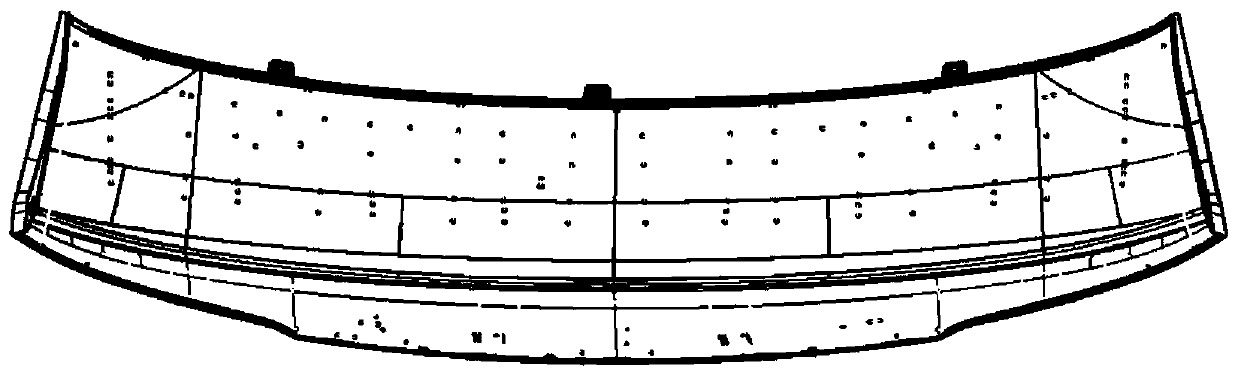

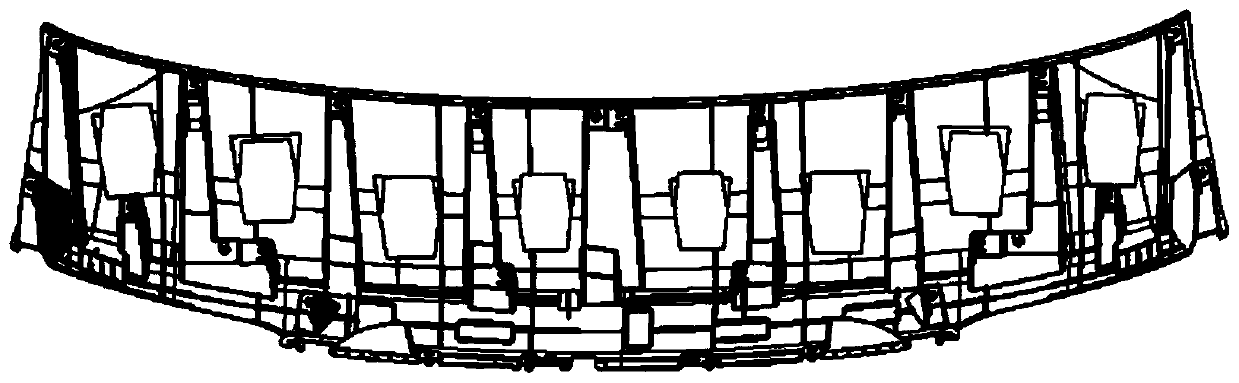

[0026] Such as figure 1, figure 2 As shown, the present invention is an automobile tailgate assembly, which includes an integrally injection-molded tailgate panel. The inner wall of the tailgate panel is provided with a locking structure connected to the tailgate lock of the rear wall panel of the vehicle body. The locking structure is close to the tailgate panel and its free The inner wall of the tailgate panel is fixedly provided with a hinge shaft hinged with the rear end of the roof; the tailgate panel is clamped with a taillight box.

[0027] The process of processing the automobile tailgate in the automobile tailgate assembly includes the following process steps:

[0028] S1: Material preparation: The amount of material to be prepared is based on the ratio of polycarbonate and ABS plastic ×: ×, and the proportion of recycled materials is less than 10%;

[0029] S2: Use a dehumidifier to dry the prepared materials, use a moisture meter to detect the moisture content of...

Embodiment 2

[0043] The difference from Embodiment 1 is that, as image 3 , Figure 8 As shown, the specific parameters for making the tailgate for the Lynk & Co DCY11 model are as follows:

[0044] Material requirements:

[0045] Tailgate cover outer panel: PC+ABS HAC8265G (black)

[0046] Tailgate cover inner panel: PC+ABS HAC8265G (black)

[0047] The material meets the requirements of "E-TP-GEELY801";

[0048] Before injection molding, raw material drying requirements: 95-105°C, 4-6h;

[0049] Ontology requirements:

[0050] product weight:

[0051] The weight of the plastic part of the outer panel of the tailgate cover: 1252±5g, the weight of the plastic part of the inner panel of the tailgate cover: 924±5g.

Embodiment 3

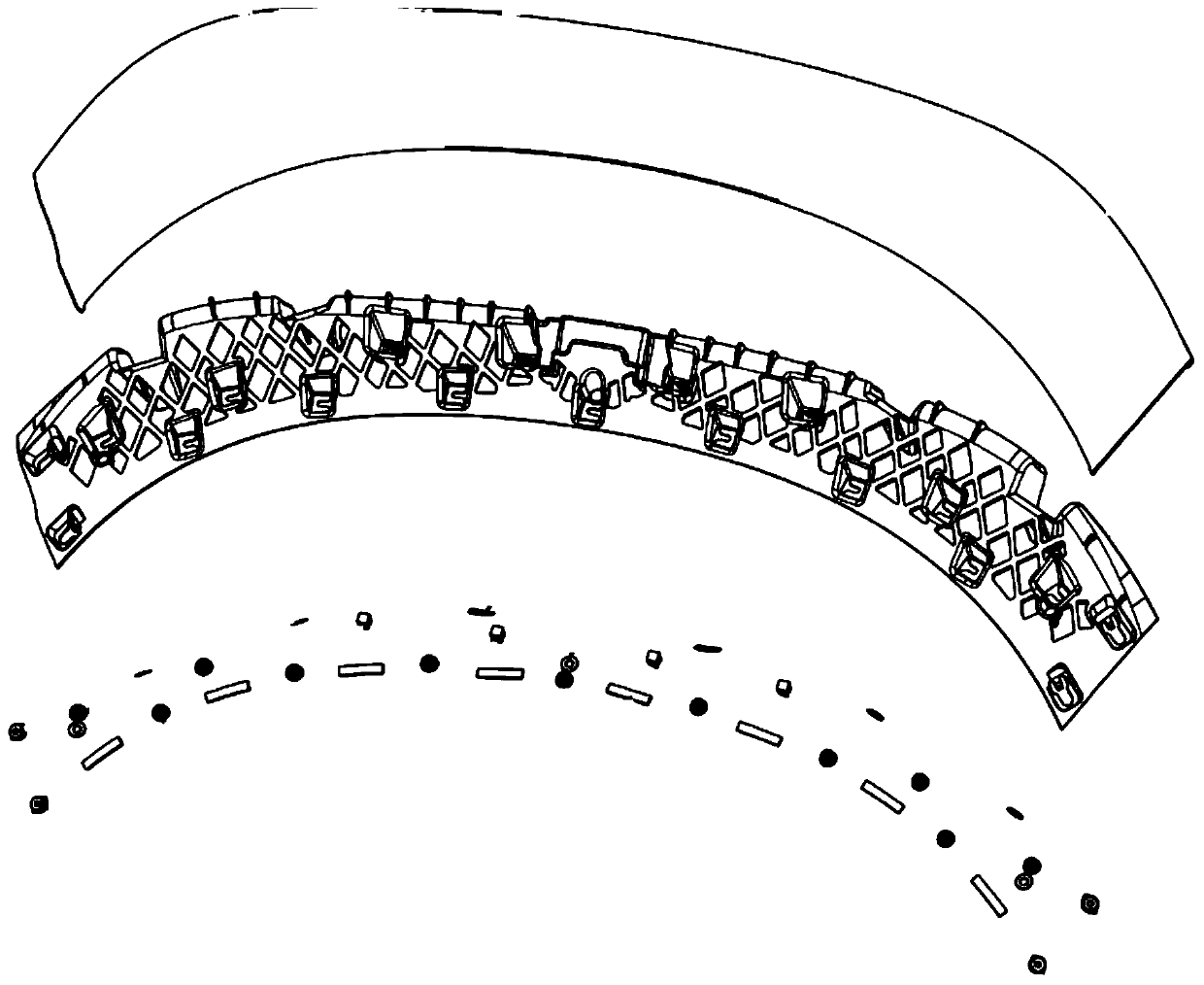

[0053] The difference from Embodiment 1 is that, as Figure 4 to Figure 7 shown (for ease of illustration, Figure 4 Blind holes and elastic friction layers are not shown; Figure 5 spring not shown; Figure 6 Blind holes are not shown; Figure 7 The blind hole and the elastic friction layer are not shown), the tailgate plate 1 is provided with a through hole 2, the through hole 2 is arranged near the free end of the tailgate plate 1, the through hole 2 is triangular prism or prism shape and the large size of the through hole 2 The end faces to the outside of the vehicle body, and is fitted with the through hole 2 to form a triangular prism-shaped locking member 3 hinged on the rear panel of the vehicle body. The vertical cross-sectional shape of the through hole 2 parallel to the traveling direction of the car body is trapezoidal, and the angle between the waist of the trapezoid and the horizontal plane near the wheel is smaller than the angle between the other waist and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com