Fiber preheating device for pultrusion of composite material products and pultrusion preheating method thereof

A composite material and heating method technology, which is applied in the field of fiber heating devices, can solve problems such as product defects, uneven speed fiber heating, etc., and achieve the effects of convenient operation, reasonable structure design, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

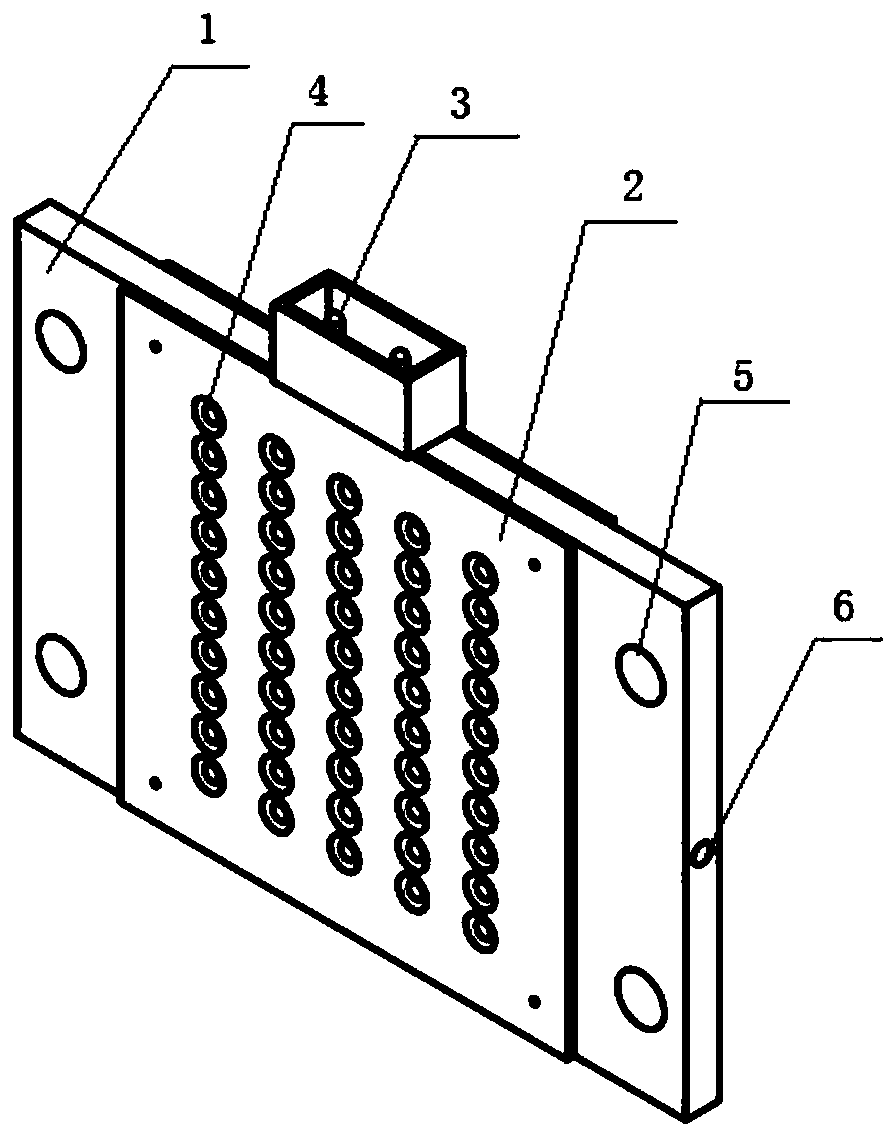

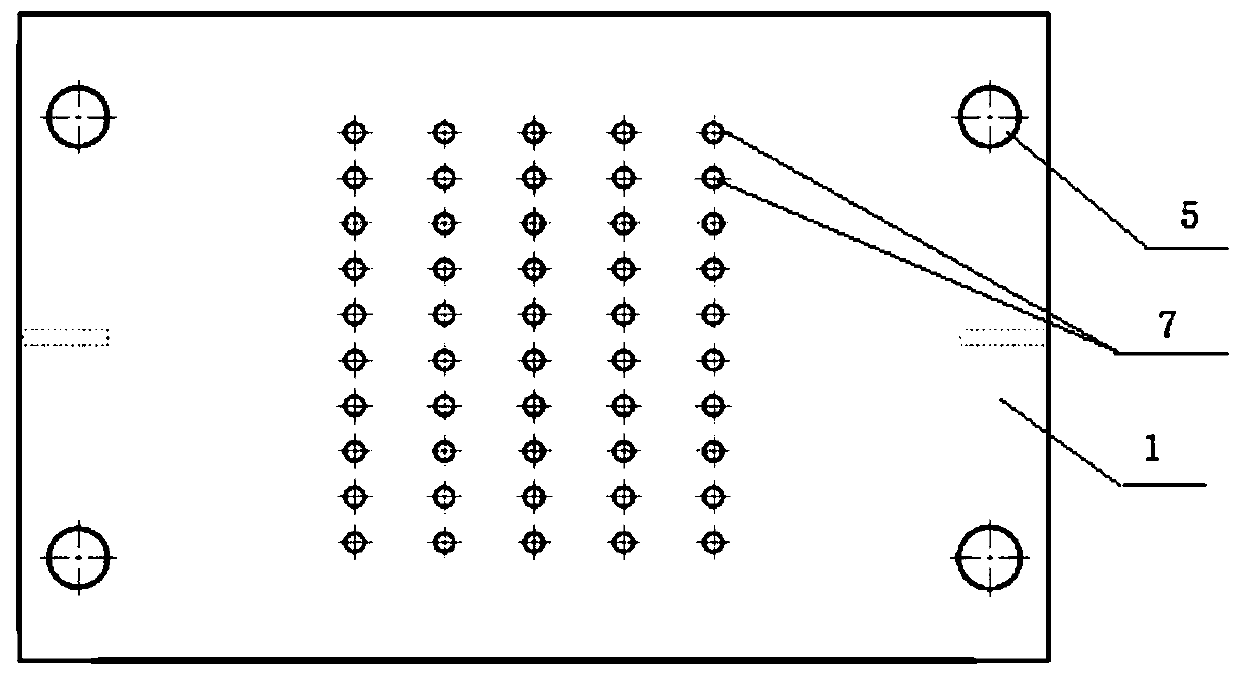

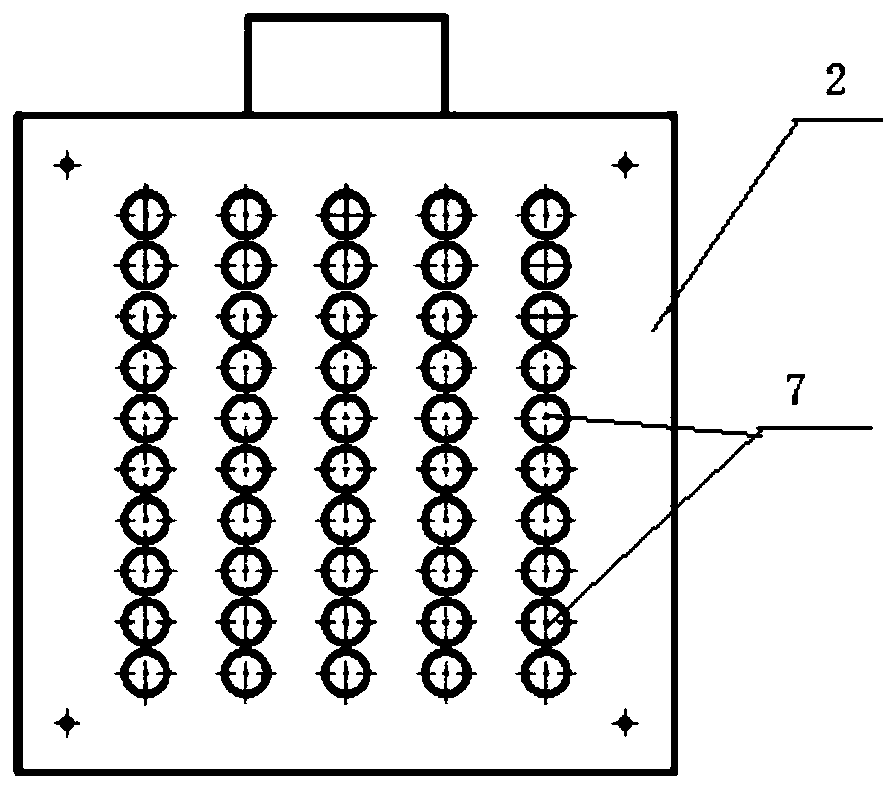

[0028] Such as Figure 1 to Figure 4 , a fiber preheating device for pultruded composite products, which includes a PTFE extruded sheet 1, an electric heating aluminum plate 2 fixed to the PTFE extruded sheet 1 by bolts, and a power plug connected to the electric heating aluminum sheet 2 3. Both the PTFE extruded rubber plate 1 and the electric heating aluminum plate 2 are provided with 50 counterbore holes 7 of equal size, and the small mouth 4 passes through the counterbore holes on the PTFE extruded rubber plate 1 and the electric heating aluminum plate 2; The outer periphery of the PTFE extrusion board 1 is provided with a through hole 5 matched with the pre-cured mold tooling,

[0029] The two sides of the electric heating aluminum plate 2 are respectively provided with temperature measuring holes 6 .

[0030] The pre-curing mold is composed of PTFE extrusion board, small nozzle and electric heating aluminum plate, in which the small nozzle is installed on the correspond...

Embodiment 2

[0032] A fiber heating method for a pultruded composite product, comprising the steps of:

[0033] Step a: Tightly connect the PTFE extrusion board 1 and the electric heating aluminum board 2 with bolts through the screw holes;

[0034] Step b: install small nozzles 4 in sequence on the counterbore corresponding to the PTFE extrusion board 1 and the electric heating aluminum board 2;

[0035] Step c: through the through hole 5 reserved on the PTFE extruded sheet 1, fix the spliced PTFE extruded sheet 1, the electric heating aluminum plate 2 and the small nozzle 4 on the pre-cured mold;

[0036] Step d: Pass the glass fiber through the PTFE extrusion board 1 and the small nozzle 4 on the electric heating aluminum plate 2, plug in the power plug 3 above the electric heating aluminum plate 2 and heat it to 80-140°C;

[0037] Step e: Under the traction of the tractor, the glass fiber passes through the resin glue tank, and then passes through the PTFE extrusion board 1 for extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com