Hot-rolled strip steel surface defect detection method based on generative adversarial network

A technology for hot-rolled steel strip and defect detection, applied in biological neural network models, artificial life, biological models, etc., can solve problems such as low fitting degree and few data samples, achieve data sample enhancement, avoid gradient descent, good recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

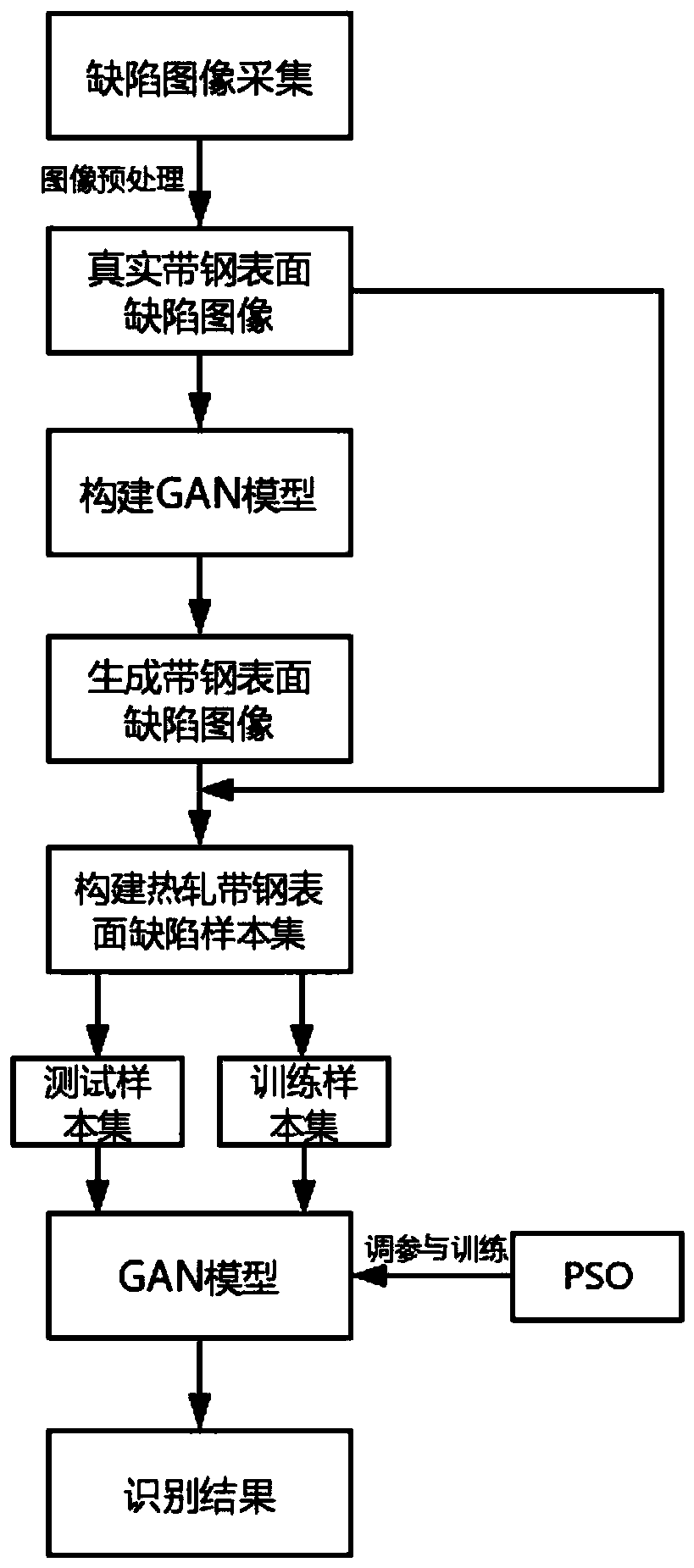

[0031] Such as figure 1 Shown as the realization process of the present invention is as follows:

[0032] Step 1: Collect defect images of hot-rolled strip steel at the industrial site, and do preliminary image preprocessing.

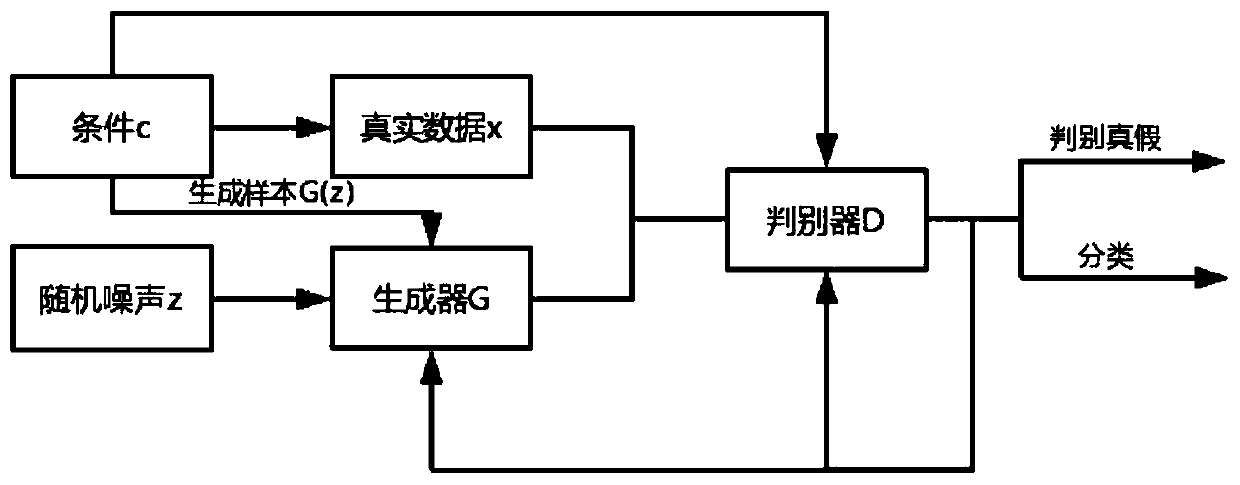

[0033] Step 2: Build and optimize the generative confrontation network model, input the processed real strip surface defect images and condition labels into the model, and observe the output generated images.

[0034] Step 3, the generated image is mixed with the collected hot-rolled strip surface defect image, and the image is processed as a hot-rolled strip surface defect sample set.

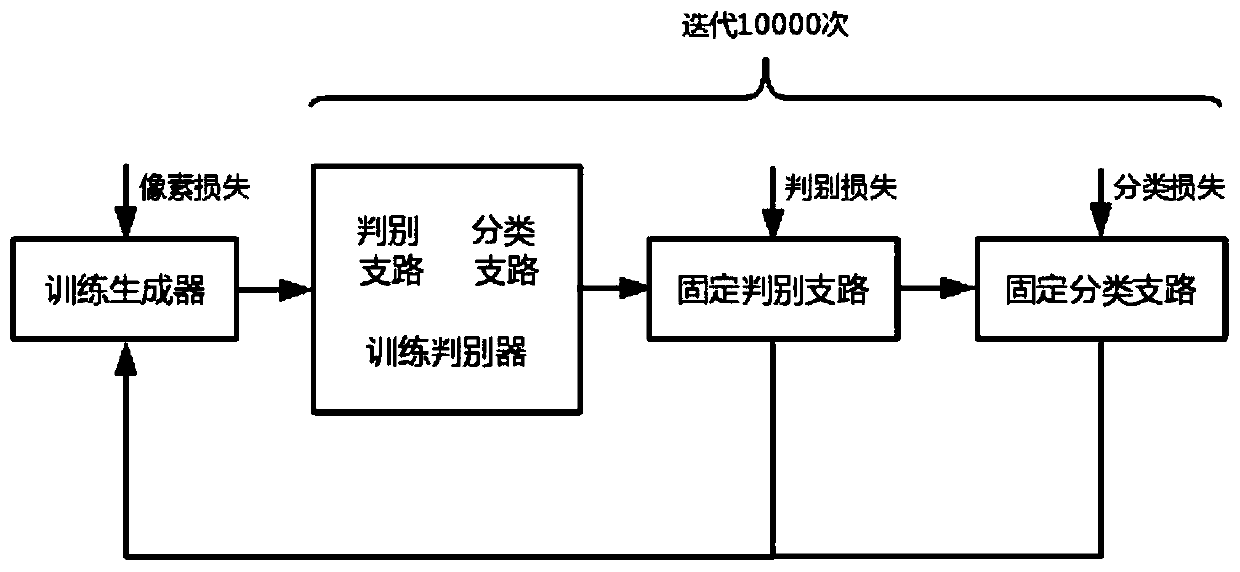

[0035] Step 4: Use the particle swarm optimization algorithm to train the improved GAN, extract the discriminant model as a classifier, adjust the parameters, and effectively identify the hot-rolled strip defect sample image data and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com