Pressure self-supply hybrid sliding bearing applied to gear pump

A sliding bearing, dynamic and static pressure technology, applied in the direction of bearings, liquid cushion bearings, shafts and bearings, etc., can solve the problems of small oil film thickness, low reliability, bumping and other problems, and achieve increased oil film thickness, high reliability, and improved The effect of operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

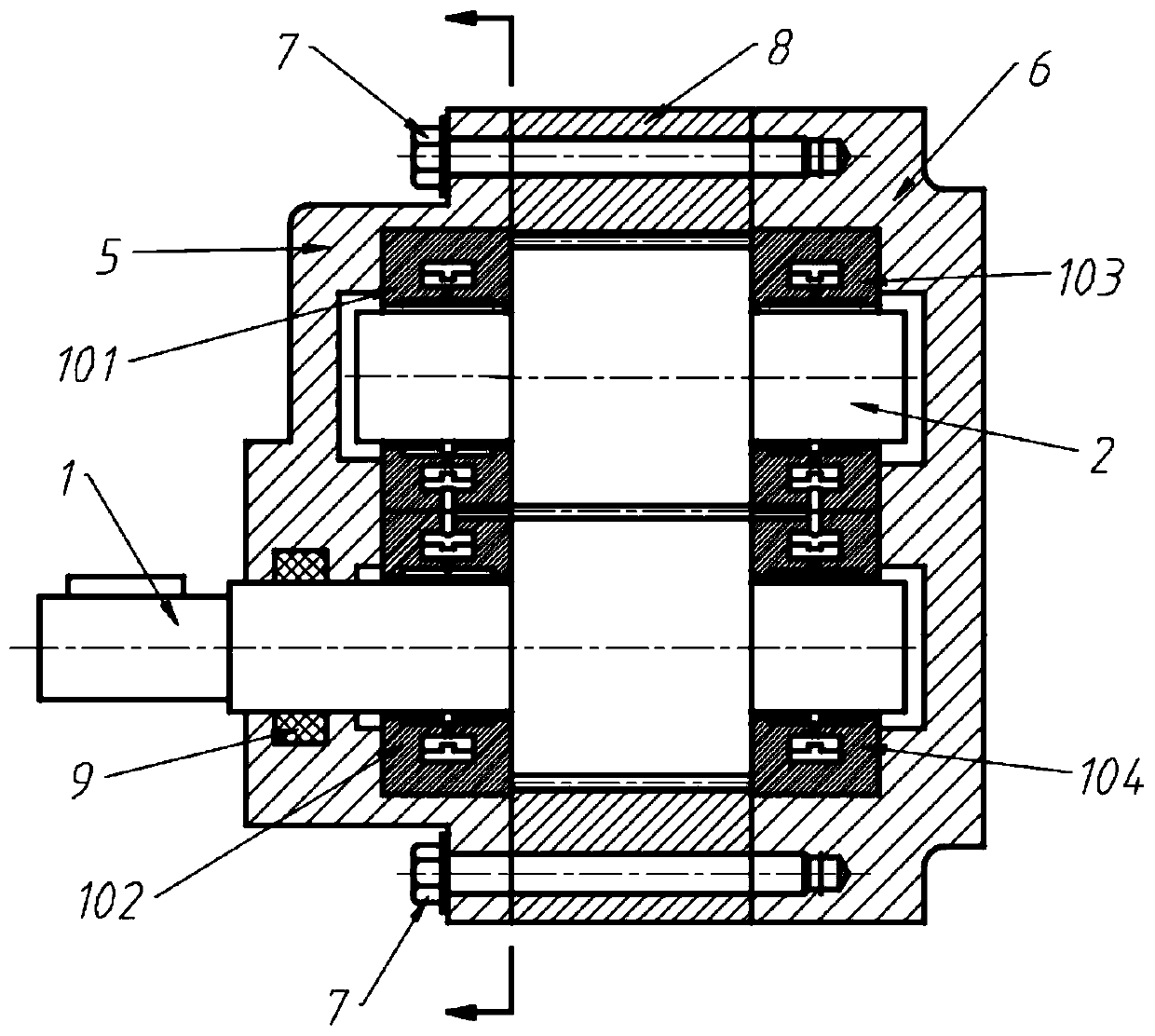

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a pressure self-supply dynamic and hydrostatic sliding bearing for gear pumps, including a driving gear shaft 1, a driven gear shaft 2, a front base 5, a rear base 6, a middle base 8, and a Drive shaft front end bearing 101 , drive shaft front end bearing 102 , driven shaft rear end bearing 103 and drive shaft rear end bearing 104 .

[0030] Such as figure 1 As shown, the inner wall of the front end bearing 101 of the driven shaft is assembled with the front journal of the driven gear shaft 2, and the outer side of the front end bearing 101 of the driven shaft is assembled with the front base 5; The front end journals are assembled together, the outer side of the front end bearing 102 of the driving shaft is assembled with the front base 5, and there is a sealing ring 9 between the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com