Threaded pile drill pipe for reinforcing local silt layer and pile forming method thereof

A technology of silt layer and threaded piles, which is applied in the field of civil engineering pile forming technology, can solve the problems of loose concrete pile density, difficult control of pump pressure, and unavailable threaded piles, etc., to achieve reduced attenuation, controllable operation, and expanded spraying The effect of radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

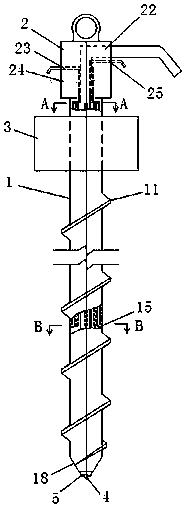

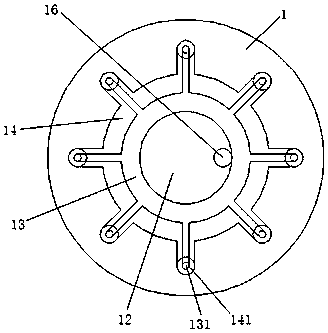

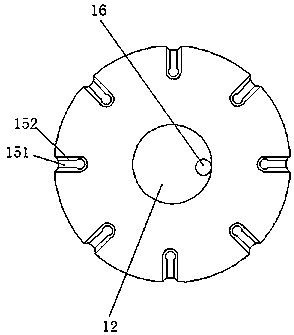

[0033] Such as Figure 1 to Figure 6As shown, a threaded pile drill pipe for reinforcing local silt layers according to the present invention includes a drill pipe 1, a rotary jet drilling tool diverter 2, and a power device 3. The surface of the drill pipe 1 has threads 11, and the inner shaft center Up and down through the perfusion chamber 12, the top of the drill pipe 1 is rotatably connected to the diverter 2 of the rotary jet drilling tool, the upper part of the drill pipe 1 is sleeved with the power unit 3, and the upper part of the drill pipe 1 is provided with a powder ring coaxial with the perfusion chamber 12 Cavity 13 and air ring cavity 14, and the rotary grouting drilling tool splitter 2 is equipped with a corresponding drill pipe perfusion cavity, powder ring cavity, and air ring cavity channel (that is, perfusion cavity channel 22, powder ring cavity channel 23, and air ring cavity channel 24 ), the outer entrances of each channel are respectively used to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com